Preparation method of long-chain alkyl amidopropyl dimethylamine with CO2 responsiveness

A technology of alkyl acid amidopropyl dimethylamine and CO2, which is applied in the field of preparation and purification of long-chain alkyl acid amidopropyl dimethylamine, can solve the problem of not having good conversion efficiency and purification steps, high temperature, and no There are problems such as reaction catalyst, purification process and final product characterization, so as to achieve the effect of high yield, simple method and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

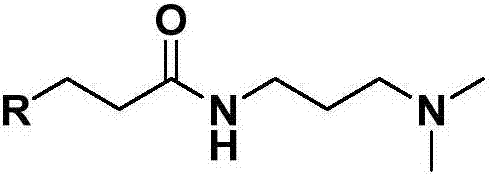

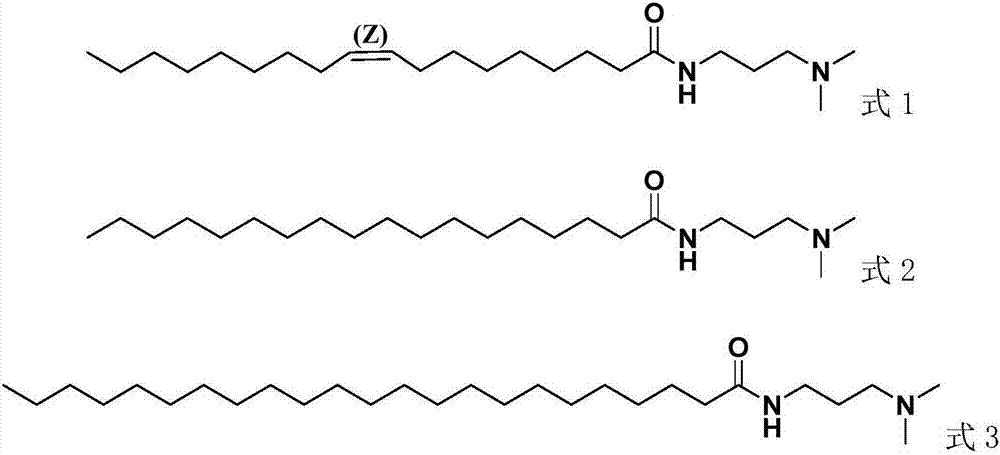

[0029] 1) Add stearic acid and N,N-dimethylaminopropylamine in a molar ratio of 1:1.1 into a three-necked flask with a condenser tube and a fractionating head, add sodium fluoride as a catalyst, and add calcium chloride as a catalyst in the fractionating head. The water remover is used to separate the by-product water in time, so that the reaction proceeds in the forward direction, and the condensation reaction is carried out under the protection of nitrogen gas, the reaction temperature is 130-150°C, and the reaction time is 8 hours.

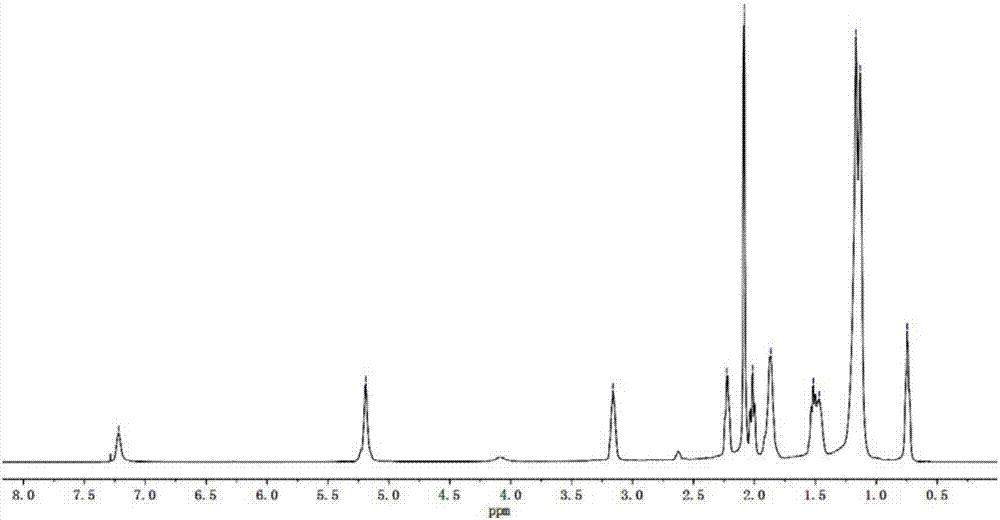

[0030] 2) Then the unreacted dimethylaminopropylamine was removed by rotary evaporation, washed several times with a mixed solution of acetone and water ratio of 2:1 until colorless, filtered, and dried to obtain C 23 h 48 N 2 O White solid. Yield: 99%, 1 HNMR(400MHz,Chloroform-d)δ7.22s,(s,1H),3.47(J=2.6Hz,1H),2.28(J=9.4Hz,2H),2.11–1.95(8H),1.84(2H), 1.51 (2H), 1.13 (J=13.2Hz, 28H), 0.78 (J=6.1, 3H). Elemental analysis results: theoretical...

Embodiment 2

[0032] Add oleic acid and N,N-dimethylaminopropylamine in a molar ratio of 1:1.1 into a three-necked flask with a condenser and a fractionating head, add sodium fluoride as a catalyst, and add calcium chloride as a water remover in the fractionating head In order to separate the by-product water in time and make the reaction proceed in the direction of positive reaction, the condensation reaction is carried out under the protection of nitrogen gas, the reaction temperature is 130-150°C, and the reaction time is 8 hours. Then the unreacted dimethylaminopropylamine was removed by rotary evaporation, washed several times with a mixed solution of acetone and water at a ratio of 2:1 until colorless, separated, and dried to obtain C 23 h 46 N 2 O dark yellow liquid. Yield: 99%, 1 HNMR (400MHz, Chloroform-d) ppm: δ7.22 (s, 2H), 5.19 (J = 2.5Hz, 2H), 3.17 (J = 4.5Hz, 2H), 2.22 (J = 9.1, 6.4Hz, 3H) , 2.12–1.88 (10H), 1.87 (s, 3H), 1.69–1.22 (7H), 1.15 (J=13.2Hz, 20H), 0.74 (J=6.3, ...

Embodiment 3

[0034] Add palmitic acid and N,N-dimethylaminopropylamine in a molar ratio of 1:1.1 into a three-necked flask with a condenser tube and a fractionating head, add sodium fluoride as a catalyst, and add calcium chloride in the fractionating head as a dehydrator In order to separate the by-product water in time, the reaction proceeds to the forward reaction direction, and the condensation reaction is carried out under the protection of nitrogen gas, the reaction temperature is 130-150 ° C, and the reaction time is 8 hours. Then the unreacted dimethylaminopropylamine was removed by rotary evaporation, washed several times with a mixed solution of acetone and water at a ratio of 2:1 until colorless, filtered, and dried to obtain C 21 h 44 N 2 O white solid powder. Yield: 99%, 1HNMR(400MHz,Chloroform-d)ppm:δ7.20(s,1H),3.29(2H),2.38(2H),2.15(8H),1.51(2H),1.16-1.21(J=11.2Hz,26H) , 0.74 (t, J=4.7Hz, 3H). Elemental analysis results: theoretical value: C, 74.06; H, 13.02; N, 8.22; O,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com