Copper indium gallium diselenide thin film solar cell back electrode and preparation method thereof

A solar cell, copper indium gallium selenide technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems such as the decrease in the binding force between the absorber layer and the back electrode, the impact of subsequent battery processing, and the impact on the photoelectric conversion rate of CIGS thin film batteries. Achieve the effect of avoiding reaction and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

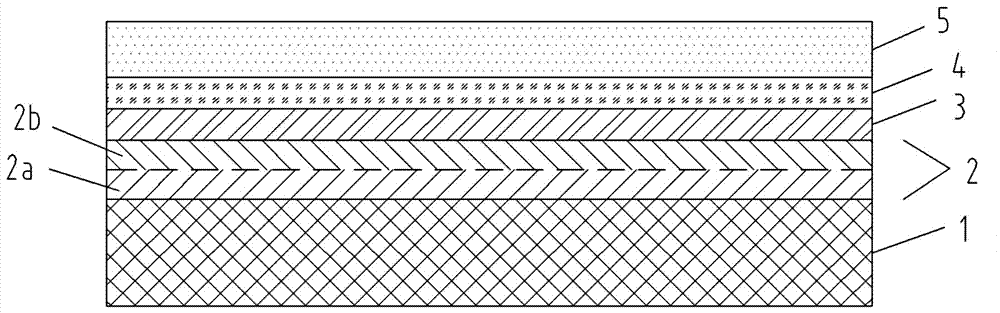

[0026] Such as figure 1 As shown, the present invention provides a back electrode of a copper indium gallium selenide thin film solar cell, including a substrate 1, a metal conductive layer 2, a barrier layer 3, a Na alloy layer 4 and an outer protective conductive layer 5 arranged in sequence from bottom to top;

[0027] Substrate 1 adopts glass substrate; Metal conductive layer 2 is wherein one or more than two kinds of Mo, W, Ta, Cu, as preferred, this embodiment adopts Mo, by Mo conductive inner layer 2a and Mo conductive outer layer 2b constitutes,

[0028] The thickness is 100-500nm in total.

[0029] The barrier layer 3 is transition metal nitride or oxynitride, titanium oxynitride is used in this embodiment; the thickness is 10-80 nm.

[0030] The Na alloy layer 4 is composed of Na and another alloy element, and the Na content in the Na alloy layer is 2 to 10% molar ratio; the thickness of the Na alloy layer 4 is 20 to 50 nm; the other in the Na alloy layer One allo...

Embodiment 2

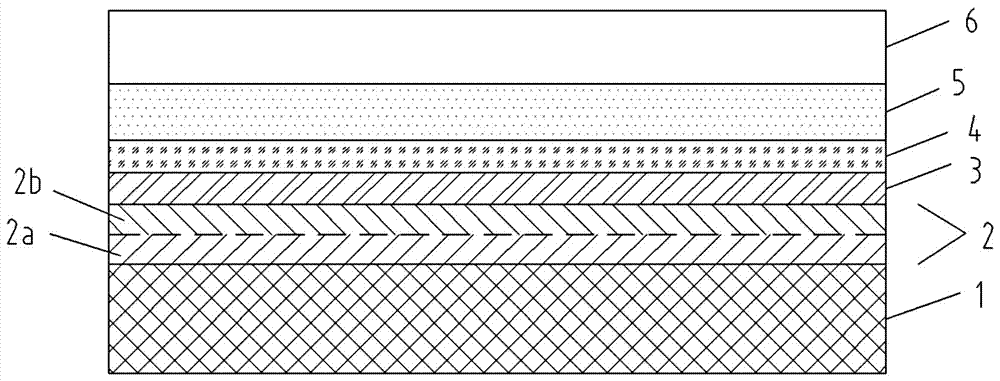

[0044] Such as figure 1As shown, the present invention provides a back electrode of a copper indium gallium selenide thin film solar cell, including a substrate 1, a metal conductive layer 2, a barrier layer 3, a Na alloy layer 4 and an outer protective conductive layer 5 arranged in sequence from bottom to top;

[0045] The substrate 1 adopts a flexible stainless steel substrate; the metal conductive layer 2 is one or more of Cr, Mo, W, Ta, Cu, as preferred, this embodiment uses Cr, Mo and Cu, and the conductive inner layer of Cr 2a is composed of MoCu alloy conductive outer layer 2b, with a total thickness of 100-500nm.

[0046] The barrier layer 3 is transition metal nitride or oxynitride, molybdenum nitride is used in this embodiment; the thickness is 10-80 nm.

[0047] The Na alloy layer 4 is composed of Na and another alloy element, and the Na content in the Na alloy layer is 2 to 10% molar ratio; the thickness of the Na alloy layer 4 is 20 to 50 nm; the other in the Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com