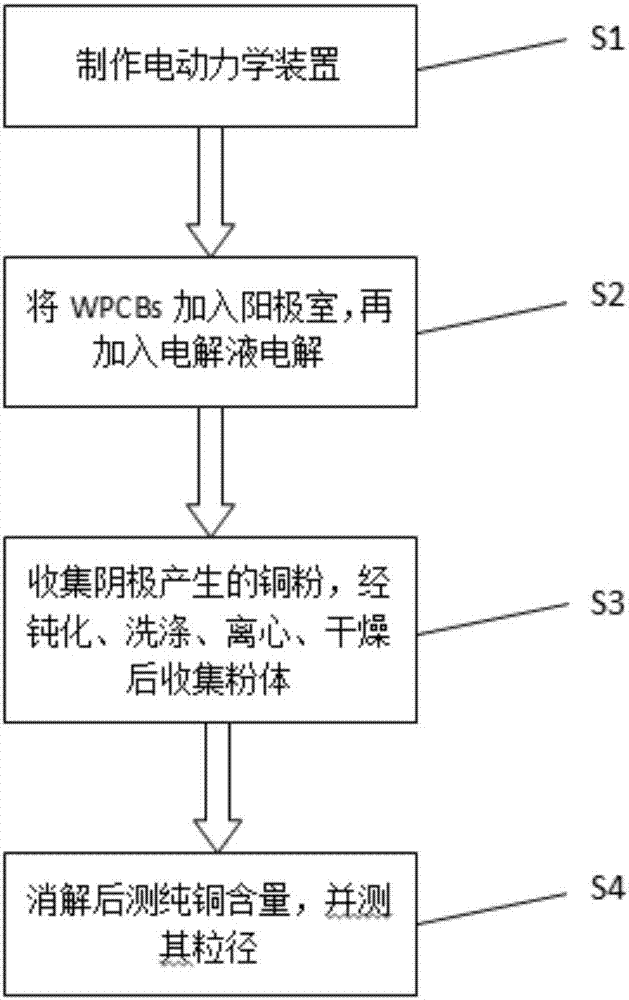

Method for recycling micro-nano copper powder from waste printed circuit boards

A printed circuit board, micro-nano technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of large particle size and uneven particle size frequency distribution of copper powder, so as to improve electronic conductivity and avoid secondary pollution , The effect of simple recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

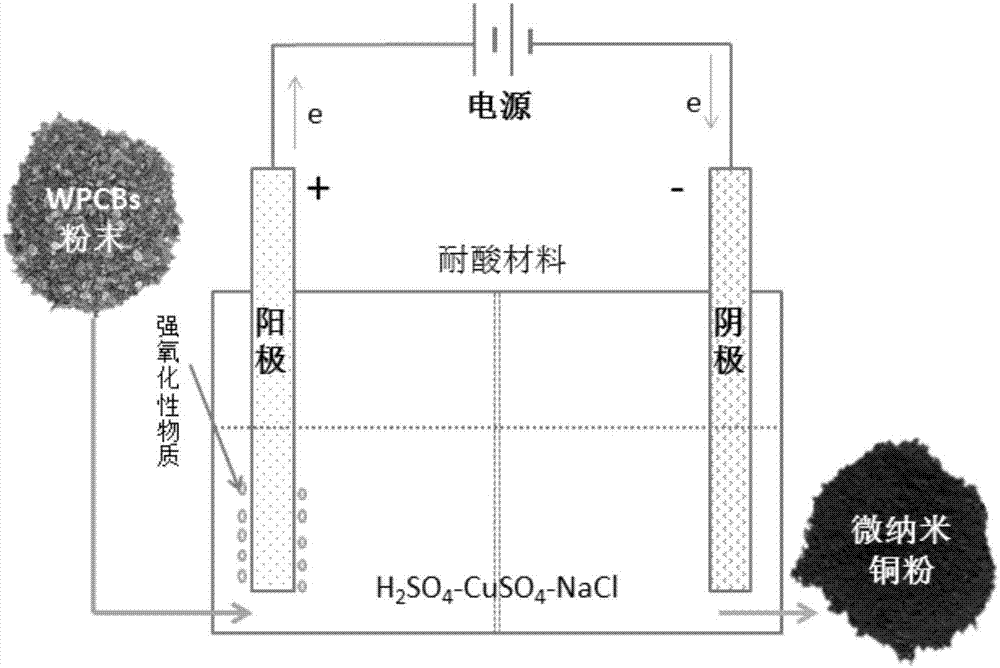

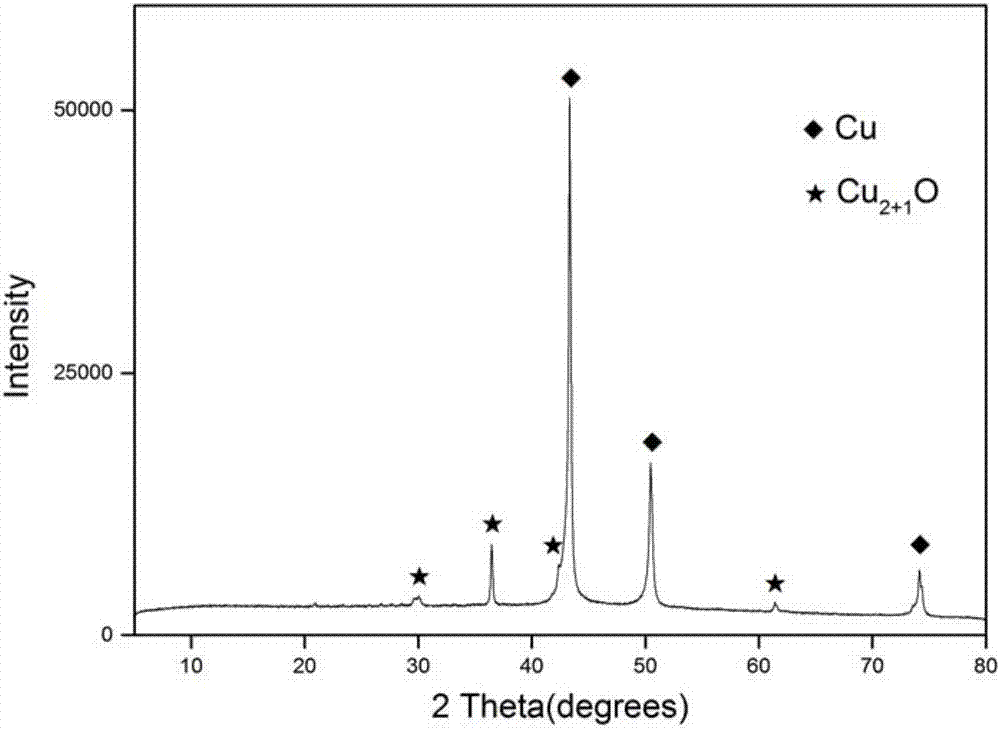

Embodiment 1

[0027] First, 6 g of metal-enriched body powder with a copper content of 80.34% after mechanical crushing and sorting was weighed and placed in the anode chamber, and a copper plate with a size of 6 cm×7 cm and a ruthenium-coated titanium plate were used as the cathode and anode, respectively; 200 mL electrolyte, the electrolyte composition is CuSO 4 ﹒ 5H 2 O (Cu 2+ 30 g / L) + NaCl (Cl - 60 g / L)+H 2 SO 4 (130 g / L) +PVP (4 g / L); Ozone was introduced into the electrolyte in the anode chamber (connected to the ozone generator, the air intake was 1.5 L / min); the power was turned on, and the current density was set to 80 mA / min. cm 2 , electrolysis 4h. After the electrolysis reaction is completed, the cathode copper plate and the copper powder deposited on the cathode are collected, and the copper powder obtained from the cathode is placed in a benzotriazole solution with a concentration of 5 g / L for passivation for 5 minutes to avoid its oxidation. Rinse three times with...

Embodiment 2

[0029] First, 6 g of metal-enriched body powder with a copper content of 80.34% after mechanical crushing and sorting was weighed and placed in the anode chamber, and a copper plate with a size of 6 cm×7 cm and a ruthenium-coated titanium plate were used as the cathode and anode, respectively; 200 mL electrolyte, the electrolyte composition is CuSO 4 ﹒ 5H 2 O (Cu 2+ 30 g / L) + NaCl (Cl - 60 g / L)+ H 2 SO 4 (130 g / L) +PVP (6 g / L); Ozone was introduced into the electrolyte in the anode chamber (connected to the ozone generator, the intake air volume was 1.5 L / min); the power was turned on, and the current density was set to 80 mA / min. cm 2 , electrolysis 4h. After the electrolysis reaction is completed, the cathode copper plate and the copper powder deposited on the cathode are collected, and the copper powder obtained from the cathode is placed in a benzotriazole solution with a concentration of 5 g / L for passivation for 5 minutes to avoid its oxidation. Rinse three ti...

Embodiment 3

[0032] First, 6 g of metal-enriched body powder with a copper content of 80.34% after mechanical crushing and sorting was weighed and placed in the anode chamber, and a copper plate with a size of 6 cm×7 cm and a ruthenium-coated titanium plate were used as the cathode and anode, respectively; 200 mL electrolyte, the electrolyte composition is CuSO 4 ﹒ 5H 2 O (Cu 2+ 30 g / L) + NaCl (Cl - 60 g / L)+ H 2 SO 4 (130 g / L) +PVP (8 g / L); Ozone was introduced into the electrolyte in the anode chamber (connected to the ozone generator, the intake air volume was 1.5 L / min); the power was turned on, and the current density was set to 80 mA / min. cm 2 , electrolysis 4h. After the electrolysis reaction is completed, the cathode copper plate and the copper powder deposited on the cathode are collected, and the copper powder obtained from the cathode is placed in a benzotriazole solution with a concentration of 5 g / L for passivation for 5 minutes to avoid its oxidation. Rinse three ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com