Lithium manganese silicate material for positive electrode material of lithium ion battery and preparation method thereof

A lithium ion battery, lithium manganese silicate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low energy density of lithium ion batteries, can not meet the requirements of electric vehicles, etc., and improve the low-voltage discharge cycle performance. , excellent electrochemical performance, the effect of improving theoretical capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

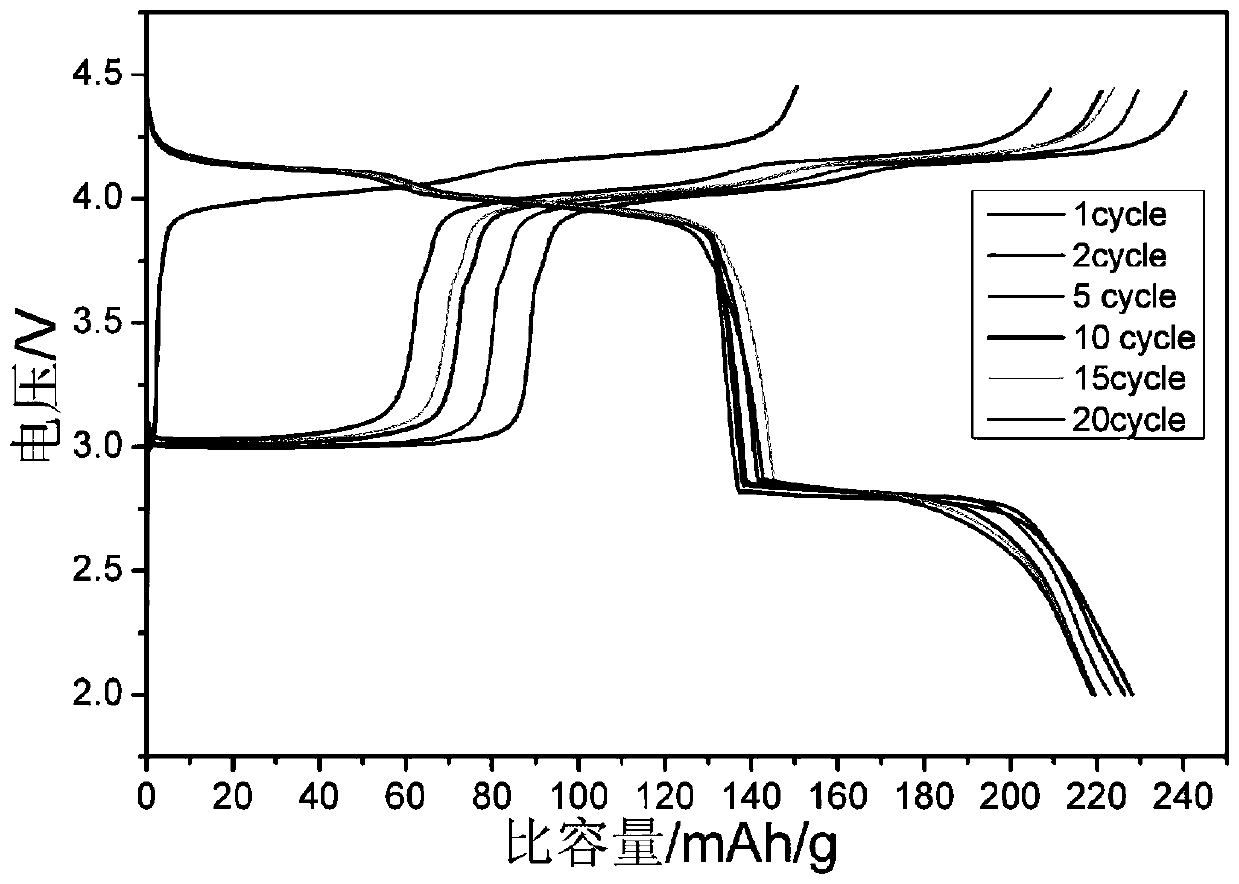

[0025] Battery preparation and electrochemical performance testing methods:

[0026] (1) Preparation of battery cathode sheet:

[0027] Mix the obtained lithium ion positive electrode material lithium manganese silicate, conductive carbon powder, and organic binder polyvinylidene fluoride (PVDF) according to the mass ratio of 8:1:1, add an appropriate amount of solvent NMP, and fully stir to form a viscous slurry The material was uniformly coated on the surface of aluminum foil, dried in a blast and then dried in a vacuum oven at 120°C for 8 hours, and the positive electrode sheet was obtained after rolling for many times.

[0028] (2) Battery assembly and performance testing:

[0029] The electrochemical performance of the lithium manganese silicate cathode material was evaluated using a 2016-type half-cell. Punch the rolled battery pole piece into a disc with a diameter of 12mm. After accurately weighing its mass, calculate the mass of lithium manganese silicate in the pol...

Embodiment 1

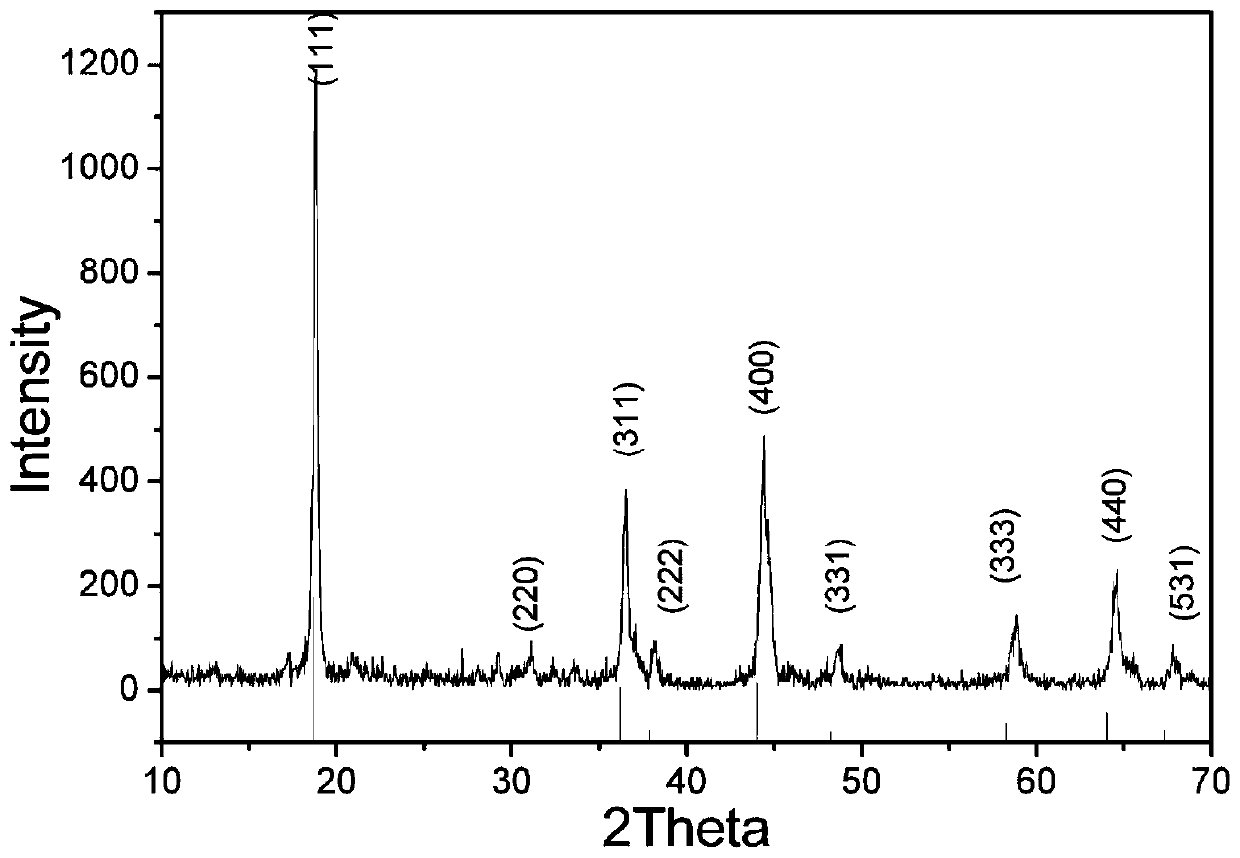

[0032] A preparation method of lithium manganese silicate lithium ion battery nano cathode material, specifically comprising the following steps:

[0033] (1) First put Li 2 CO 3 , MnO , SiO 2 40.7 parts by mass, 71 parts by mass, and 60 parts by mass, and then add 550 parts by mass of deionized water to mix the above three raw materials, and form a slurry after stirring for a period of time.

[0034] (2) Put the slurry obtained in step (1) into a nano-scale ball mill, control the grinding speed at 2000r / min, grind for 4 hours, and obtain the size D of suspended particles 50 It is a slurry of about 200nm.

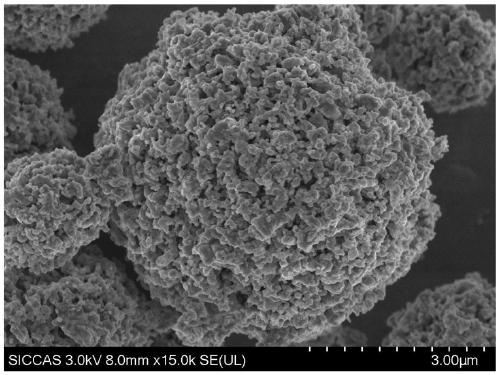

[0035] (3) The ball milling product obtained in step (2) was spray-dried at 180° C. to obtain spherical precursor powder of lithium manganese silicate.

[0036] (4) Press the precursor powder obtained in step (3) into briquettes with a pressure of 8 MPa using a tablet press.

[0037] (5) Put the block obtained in step (4) into a tube furnace for calcination, feed 90ml / ...

Embodiment 2

[0041] A preparation method of lithium manganese silicate lithium ion battery nano cathode material, specifically comprising the following steps:

[0042] (1) First put Li 2 CO 3 , MnO , SiO 2 According to the batching of 40.7 parts by mass, 71 parts by mass and 60 parts by mass, then add 550 parts by mass of deionized water to mix the above three raw materials, and form a slurry after stirring for a period of time.

[0043] (2) Put the slurry obtained in step (1) into a nano-scale ball mill, control the grinding speed at 2000r / min, grind for 3 hours, and obtain the size D of suspended particles 50 It is a slurry of about 250nm.

[0044] (3) The ball milling product obtained in step (2) was spray-dried at 180° C. to obtain spherical precursor powder of lithium manganese silicate.

[0045] (4) Press the precursor powder obtained in step (3) into briquettes with a pressure of 8 MPa using a tablet press.

[0046] (5) Put the block obtained in step (4) into a tube furnace for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com