Composite nanofiltration membrane and preparation method thereof

A technology of composite nanofiltration membrane and ultrafiltration base membrane, which is applied in the field of composite nanofiltration membrane and its preparation, can solve the problem of poor stability of modified membrane by surface modification method, difficult control of blending process, complex layer-by-layer self-assembly process, etc. problems, to achieve the effect of good hydrophilic performance, good separation performance and various forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Weigh PEG 1000 (0.125g), sodium hydroxymethylcellulose (0.125g), sodium lauryl sulfate (0.01g) and sodium hydroxide (0.05g) into 50ml of deionized water, Heat and stir to dissolve it completely, then cool to room temperature to obtain an aqueous phase solution;

[0042] (2) Soak the polysulfone ultrafiltration base membrane in the aqueous phase solution for 30 minutes;

[0043] (3) Remove excess aqueous phase solution, and then place the film in a constant temperature box to dry at 30°C (about 30min);

[0044] (4) Measure 1.0 g of hexamethylene diisocyanate and dissolve it in 50 ml of n-hexane solution to obtain an organic phase solution;

[0045] (5) Soak the dried film in the organic phase solution for 30 minutes;

[0046] (6) Remove the excess organic phase solution, place the reacted membrane in a constant temperature oven for drying at 60°C, rinse it with water, pre-press and form it, and then conduct a membrane performance test.

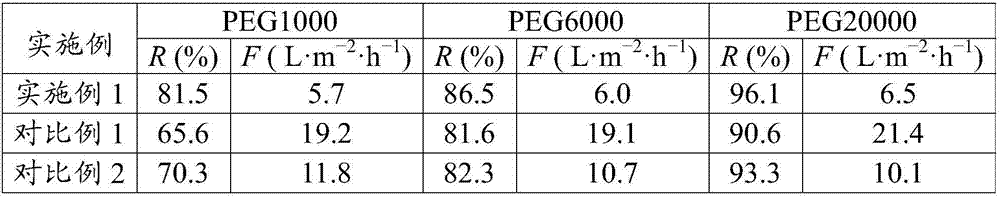

[0047] The prepared membrane...

Embodiment 2

[0068] (1) Weigh PEG200 (0.125g), sodium hydroxymethylcellulose (0.125g), sodium lauryl sulfate (0.01g) and sodium hydroxide (0.05g) into 50ml deionized water, heat Stir to dissolve it completely, then cool to room temperature to obtain an aqueous phase solution;

[0069] (2) Soak the polysulfone ultrafiltration base membrane in the aqueous phase solution for 30 minutes;

[0070] (3) Remove excess aqueous phase solution, and then place the film in a constant temperature box to dry at 30°C (about 30min);

[0071] (4) Measure 1.0 g of hexamethylene diisocyanate and dissolve it in 50 ml of n-hexane solution to obtain an organic phase solution;

[0072] (5) Soak the dried film in the organic phase solution for 30 minutes;

[0073] (6) Remove the excess organic phase solution, place the reacted membrane in a constant temperature oven for drying at 60°C, rinse it with water, pre-press and form it, and then conduct a membrane performance test.

[0074] The prepared membrane was pr...

Embodiment 3

[0076] (1) Weigh PEG600 (0.125g), sodium hydroxymethylcellulose (0.125g), sodium lauryl sulfate (0.01g) and sodium hydroxide (0.05g) into 50ml deionized water, heat Stir to dissolve it completely, then cool to room temperature to obtain an aqueous phase solution;

[0077] (2) Soak the polysulfone ultrafiltration base membrane in the aqueous phase solution for 30 minutes;

[0078] (3) Remove excess aqueous phase solution, and then place the film in a constant temperature box to dry at 30°C (about 30min);

[0079] (4) Measure 1.0 g of hexamethylene diisocyanate and dissolve it in 50 ml of n-hexane solution to obtain an organic phase solution;

[0080] (5) Soak the dried film in the organic phase solution for 30 minutes;

[0081] (6) Remove the excess organic phase solution, place the reacted membrane in a constant temperature oven for drying at 60°C, rinse it with water, pre-press and form it, and then conduct a membrane performance test.

[0082] The prepared membrane was pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com