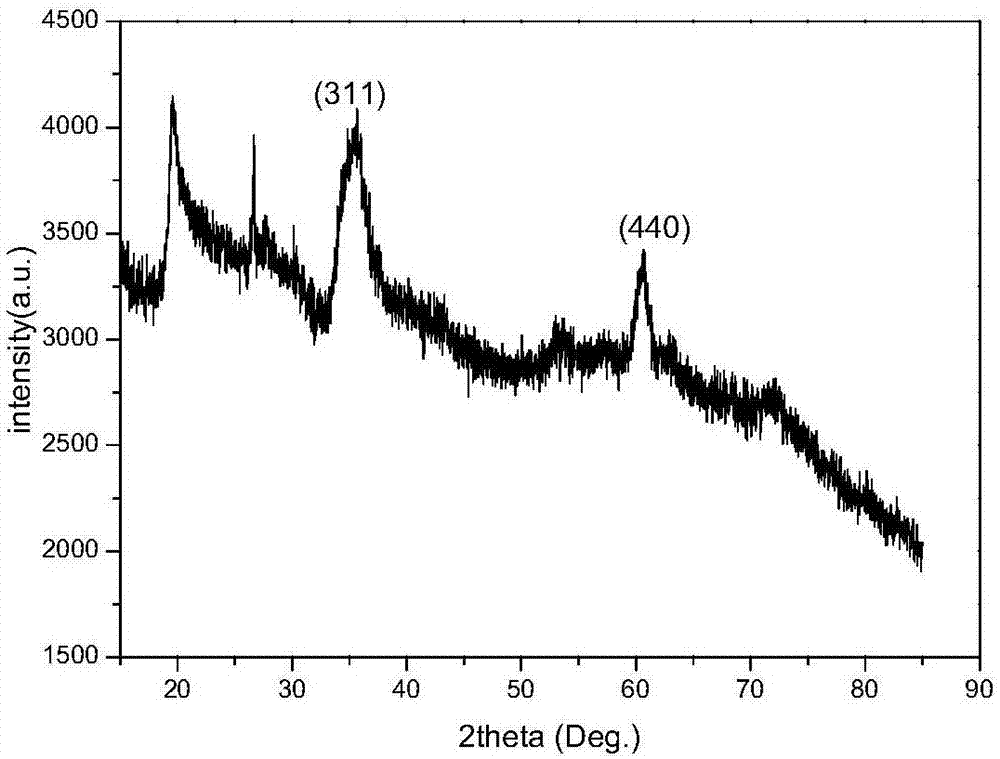

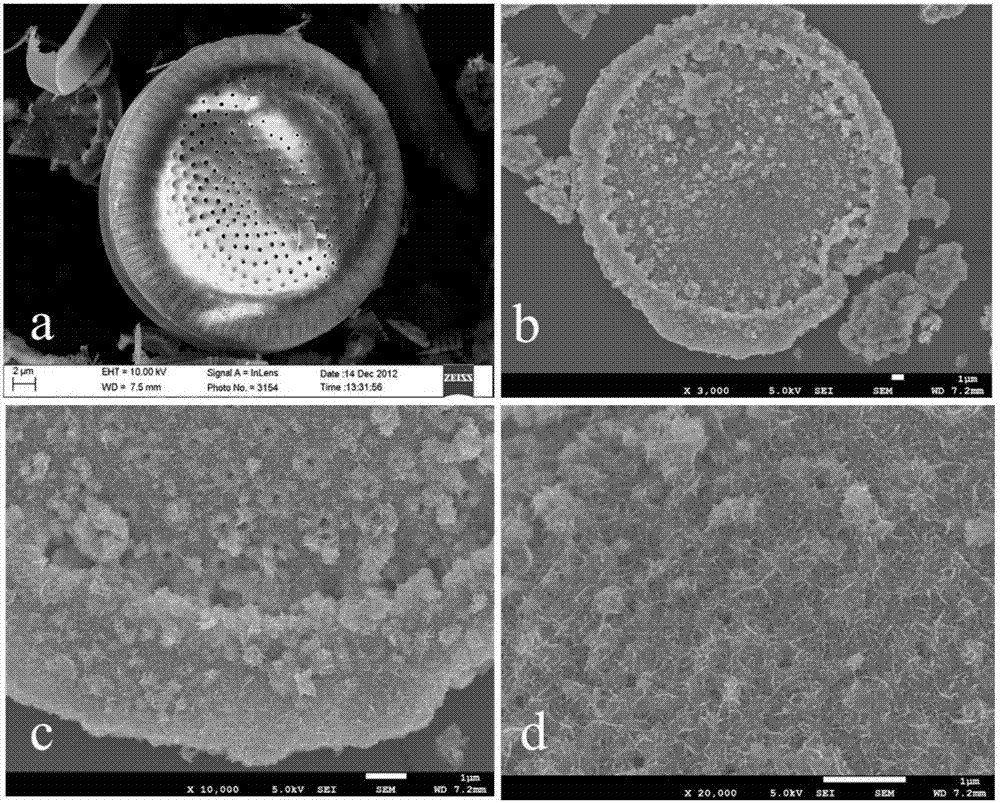

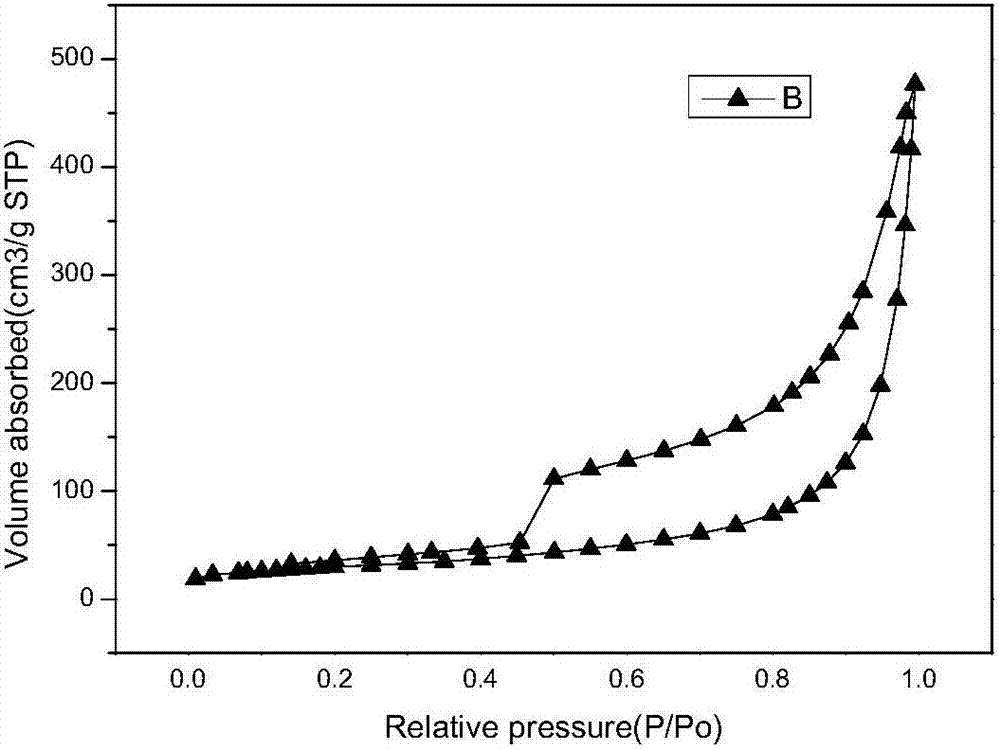

Preparation method of diatomite/magnesium ferrite composite material

A technology of composite materials and diatomite, applied in the field of materials, can solve the problems of low removal rate of heavy metal anions, low specific surface area, limited adsorption capacity, etc., and achieve the effect of solving subsequent pollution, large specific surface area and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment relates to a preparation method of a diatomite / magnesium ferrite composite material, comprising the following steps:

[0042] 1) Add 2.5g of diatomaceous earth to 30mL of ammonia water with a concentration of 25%, mix well

[0043] 2) Add 0.1 g of CTAB (cetyltrimethylammonium bromide) to the above suspension, and stir magnetically for 30 minutes at a temperature of 25°C;

[0044] 3) Weigh 1.5g MgCl 2 ·6H 2 O was added to a beaker filled with deionized water, stirred to dissolve it, then added 1.5g of ferrous oxalate powder and continued to stir to obtain a yellow suspension; Add it dropwise to the diatomaceous earth suspension at a high speed, and magnetically stir for 30 minutes at a temperature of 25°C to obtain a mixed solution;

[0045] 4) Transfer the mixed suspension to a reaction kettle, perform a hydrothermal reaction at 180°C for 8 hours for aging, cool to room temperature, wash with deionized water and absolute ethanol for 3 to 4 times, filt...

Embodiment 2

[0047] This embodiment relates to a preparation method of a diatomite / magnesium ferrite composite material, comprising the following steps:

[0048] 1) Add 2.5g of diatomaceous earth to 30mL of ammonia water with a concentration of 25%, mix well

[0049] 2) Add 0.1 g of CTAB (cetyltrimethylammonium bromide) to the above suspension and stir magnetically for 30 minutes at a temperature of 25°C;

[0050] 3) Weigh the MgCl of 2g amount 2 ·6H 2 O was added to a beaker filled with deionized water, stirred to dissolve it, then added 2g of ferrous oxalate powder and continued to stir to obtain a yellow suspension, and the above suspension was pumped with a constant flow pump at a speed of 50 drops / min Add it dropwise to the diatomite suspension, and stir magnetically for 30 minutes at a temperature of 25°C to obtain a mixed solution;

[0051] 4) Put the mixed solution in a reaction kettle, age at 180°C for 8 hours, cool to room temperature, then wash with deionized water and absolu...

Embodiment 3

[0053] This embodiment relates to a preparation method of a diatomite / magnesium ferrite composite material, comprising the following steps:

[0054] 1) Add 2.5g of diatomaceous earth to 30mL of ammonia water with a concentration of 25%, mix well

[0055] 2) Add 0.1 g of CTAB (cetyltrimethylammonium bromide) to the above suspension and stir magnetically for 30 minutes at a temperature of 25°C;

[0056] 3) Weigh the MgCl of 2g amount 2 ·6H 2 O was added to a beaker filled with deionized water, stirred to dissolve it, then added 1.5 g of ferrous oxalate powder and continued to stir to obtain a yellow suspension, and the above suspension was mixed with a constant flow pump at a rate of 50 drops / min. Add it dropwise to the diatomaceous earth suspension at a high speed, and magnetically stir for 30 minutes at a temperature of 25°C to obtain a mixed solution;

[0057] 4) Put the mixed solution in a reaction kettle, age at 180°C for 8 hours, cool to room temperature, then wash with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com