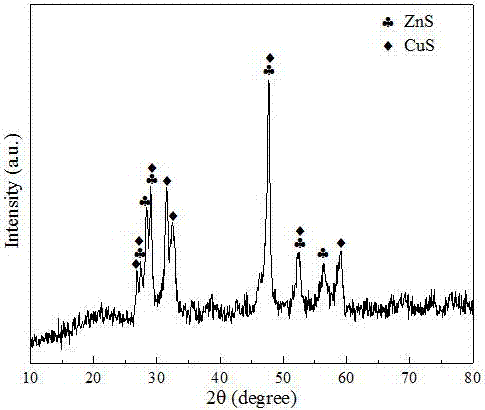

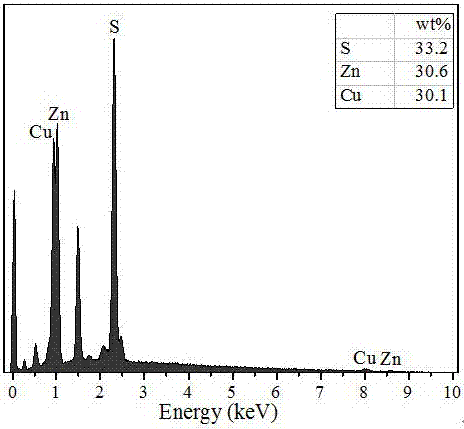

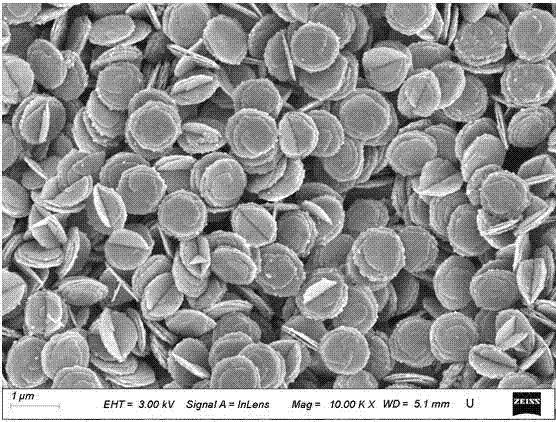

Preparation method of ZnS/CuS nanosheet composite photocatalyst

A technology of nanosheets and composite materials, which is applied in the field of preparation of ZnS/CuS nanosheet composite materials, can solve the problems of low solar energy utilization rate, difficult photocatalytic degradation, and unstable chemical properties, so as to improve light absorption efficiency and photocatalytic activity , improve the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 0.322g of copper nitrate trihydrate, 0.7934g of zinc nitrate hexahydrate, 0.6976g of thiourea, and 0.1g of polyvinylpyrrolidone (Mw=58000) into a mixed solution of acetonitrile with a volume of 160mL and a mass fraction of 50wt%, ultrasonicate for 5min, and Stir at a stirring speed of 500r / min at room temperature for 60min to form a copper-zinc mixed solution, put the above solution into a polytetrafluoroethylene high-temperature reaction kettle, and conduct a hydrothermal reaction at 200°C for 6h. After natural cooling, remove the supernatant and use The deionized water and absolute ethanol were washed three times respectively, and dried in an oven at 60°C for 5 hours, and the obtained product was a composite nanosheet with a CuS / ZnS molar ratio of 1:2.

Embodiment 2

[0037]Weigh 0.1932g of copper nitrate trihydrate, 0.9520g of zinc nitrate hexahydrate, 0.6976g of thiourea, and 0.1g of polyethylene glycol 20000 and add them to a mixed solution of acetonitrile with a volume of 140mL and a mass fraction of 50wt%. Stir at 500r / min at room temperature for 60min to form a copper-zinc mixed solution, put the above solution into a polytetrafluoroethylene high-temperature reaction kettle, and conduct a hydrothermal reaction at 200°C for 5h. After natural cooling, remove the supernatant, and use deionized water and absolute ethanol for three times, and dried in an oven at 60° C. for 5 h, and the obtained product is a composite nanosheet with a CuS / ZnS molar ratio of 1:4.

Embodiment 3

[0039] Weigh 0.7248g of copper nitrate trihydrate, 0.2974g of zinc nitrate hexahydrate, 0.6976g of thiourea, and 0.1g of sodium dodecylbenzenesulfonate into 150mL of acetonitrile mixed solution with a mass fraction of 60wt%, ultrasonicate for 5min, and Stir at a stirring speed of 500r / min and stir for 60min at room temperature to form a copper-zinc mixed solution. Put the above solution into a polytetrafluoroethylene high-temperature reaction kettle, and conduct a hydrothermal reaction at 190°C for 8h. After natural cooling, remove the supernatant and use The ion water and absolute ethanol were washed three times respectively, and dried in an oven at 60° C. for 5 h, and the obtained product was a composite nanosheet with a CuS / ZnS molar ratio of 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com