Preparation method of bismuth oxyiodate photocatalyst

A photocatalyst, bismuth oxyiodate technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of difficult removal of zero-valent mercury, complicated removal process, etc., and achieves excellent photocatalytic performance. The effect of enriching pore structure and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Measure 80ml of ethylene glycol into the beaker, weigh 0.97g of bismuth nitrate pentahydrate into the solution, and keep stirring for 30 minutes. Weigh 0.428g of potassium iodate and add it into the above solution, and continue to stir for 2 hours to form a uniformly mixed emulsion. The above emulsion was centrifugally washed three times with deionized water at a speed of 6000 rad / min, and three times with absolute ethanol at a speed of 8000 rad / min. The washed samples were dried in an oven, the drying temperature was set at 80°C, and the drying time was 8 hours. The dried samples were ground and then put into a muffle furnace for calcination, the calcination temperature was 300 degrees Celsius, and the calcination time was 1 hour. Cool naturally to normal temperature to obtain bismuth oxyiodate photocatalyst.

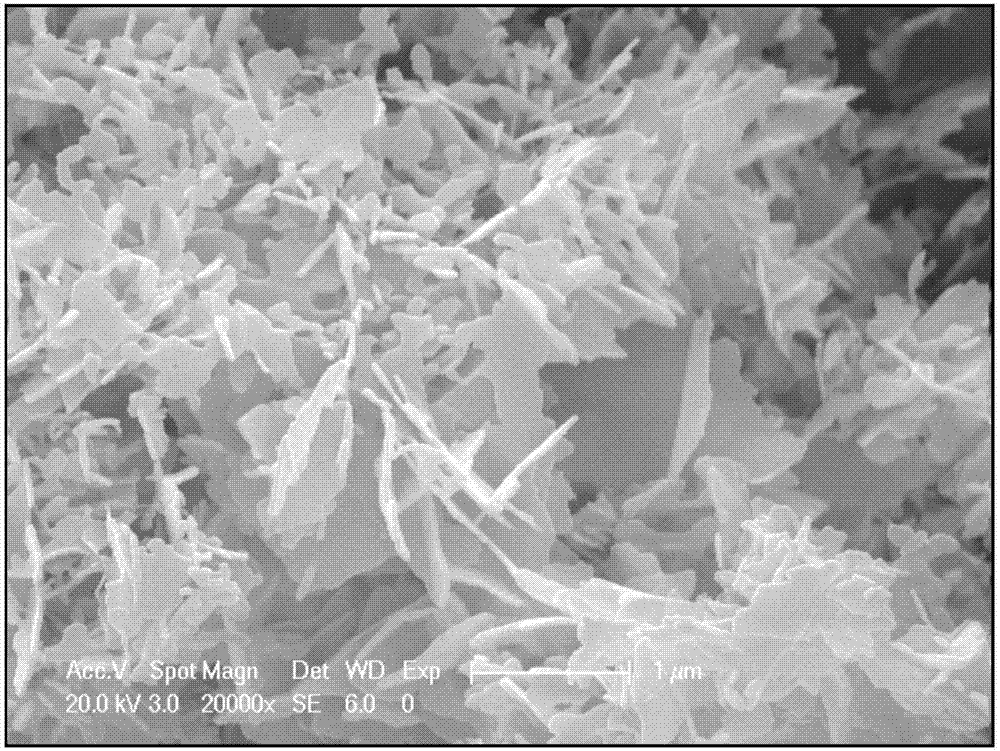

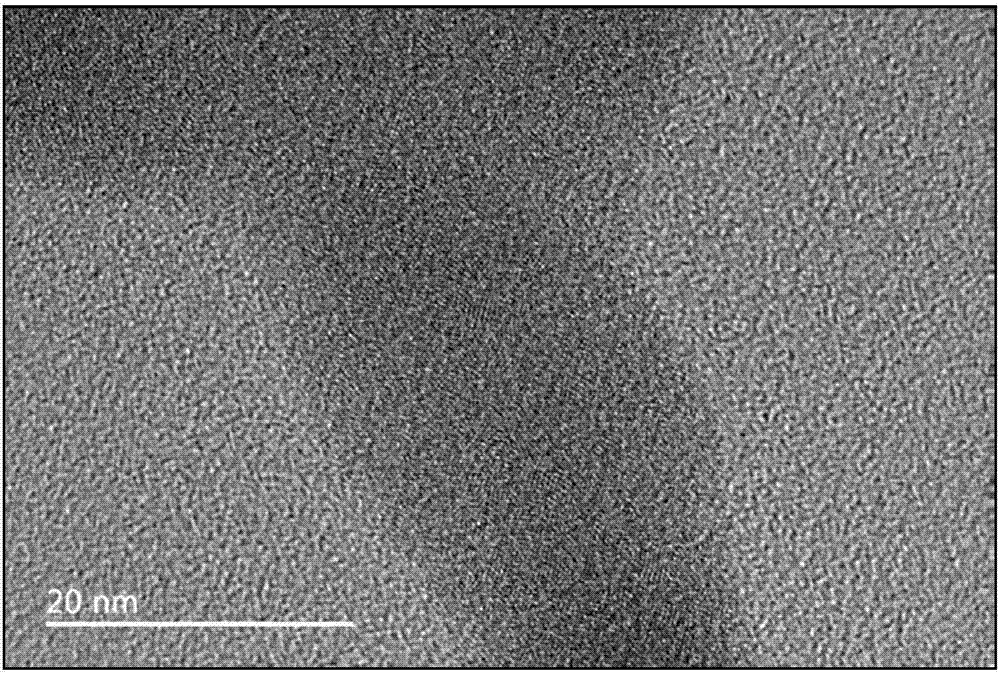

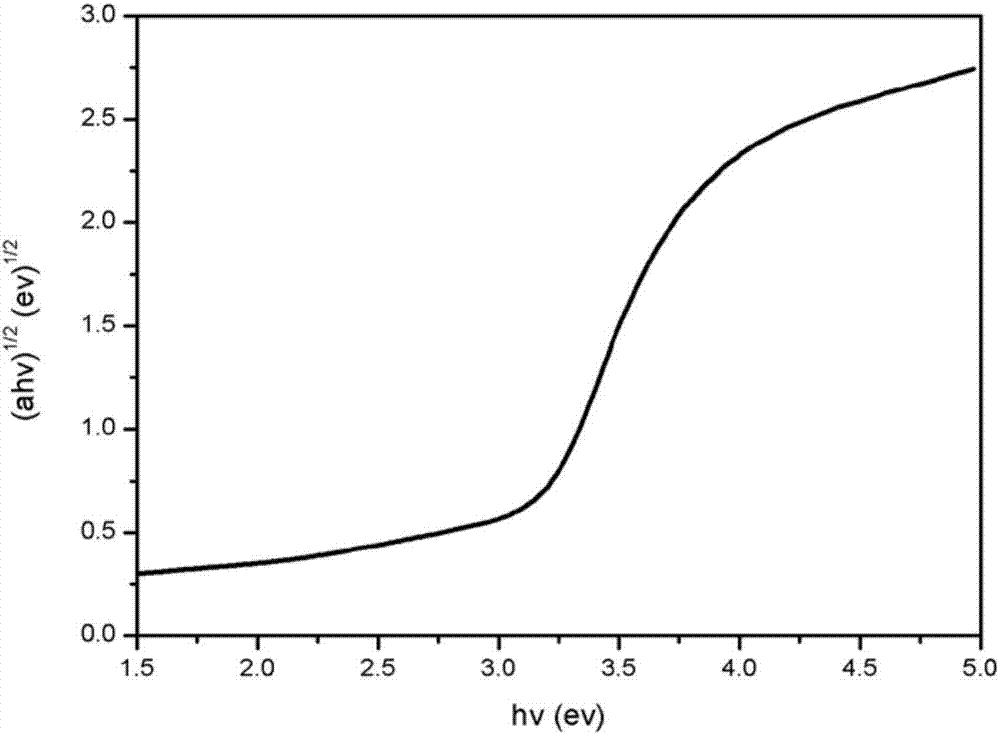

[0023] figure 1 It is an SEM picture of the prepared bismuth oxyiodate photocatalyst. It can be seen from the figure that the prepared bismuth oxyiodate phot...

Embodiment 2

[0035] The bismuth oxyiodate photocatalyst prepared in embodiment 1 is tested for its activity by removing zero-valent mercury from power plant flue gas:

[0036] The photocatalytic test was carried out at normal temperature and pressure. Take 50 mg of the catalyst sample and put it into a beaker, add 10 ml of ethanol pentahydrate, and ultrasonicate for 5 minutes with an ultrasonic disperser to obtain a uniformly dispersed ethanol pentahydrate solution of bismuth oxyiodate. The above solution was coated on a ground glass slide through a syringe, and the size of the glass slide was 80*80mm. Put the coated glass sheet into an oven to dry for 20 minutes to ensure that the catalyst adheres to the surface of the glass sheet.

[0037] Put the above-mentioned dried glass pieces into the mercury removal experimental platform, start co-adsorption equilibrium for 30 minutes, and then turn on the light to test the adsorption performance of the catalyst.

[0038] After 120 minutes of pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com