Stopping device

A shell and modifier technology, applied in the field of rubber and plastic products, can solve the problems of heavy specific gravity and laborious handling, and achieve the effects of small specific gravity, increased strength, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

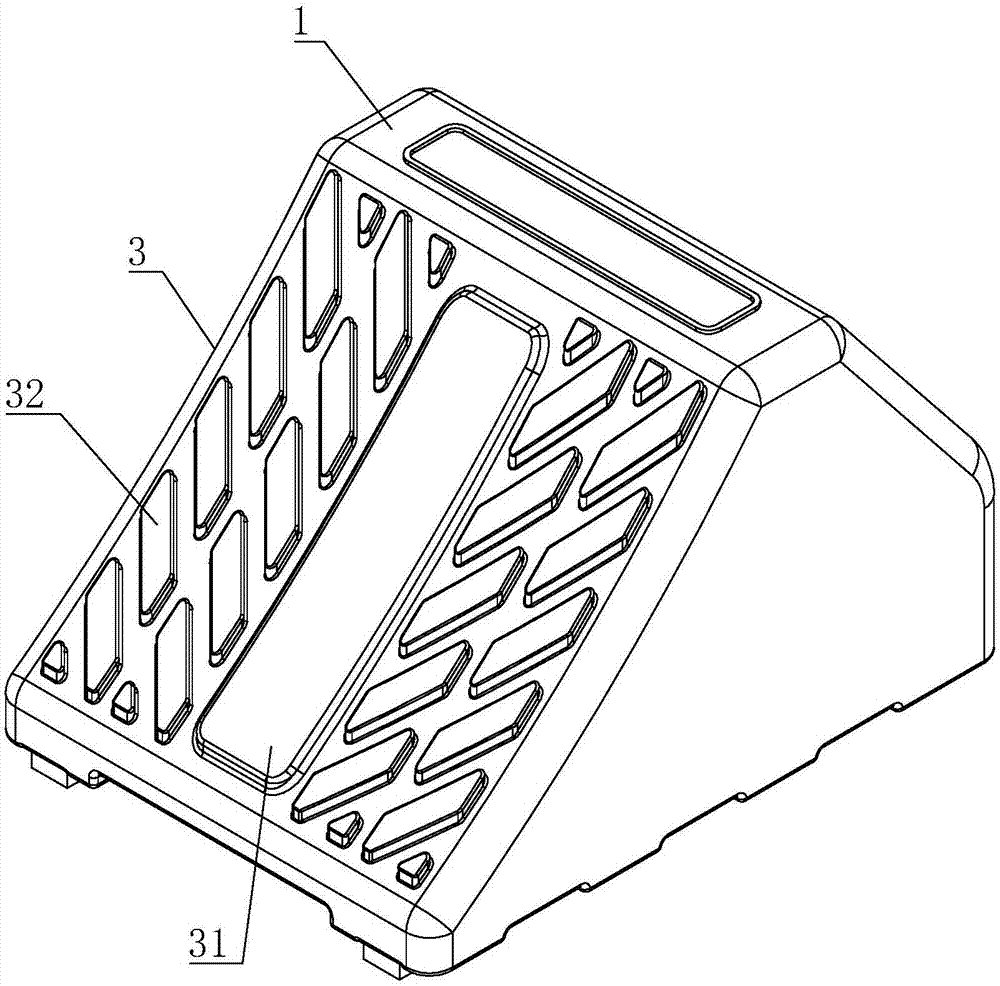

[0032] Embodiment 1: a kind of stopper, as figure 1 , figure 2 As shown, it includes a shell 1 and a hard polyurethane foam 2 inside the shell 1 . The front end of the casing 1 is provided with an inclined blocking surface 3. When the vehicle is on a slope, the stopper is placed below the vehicle wheel. The blocking surface 3 on the casing 1 touches the wheel, which plays a blocking role on the wheel and prevents the vehicle from sliding along the slope.

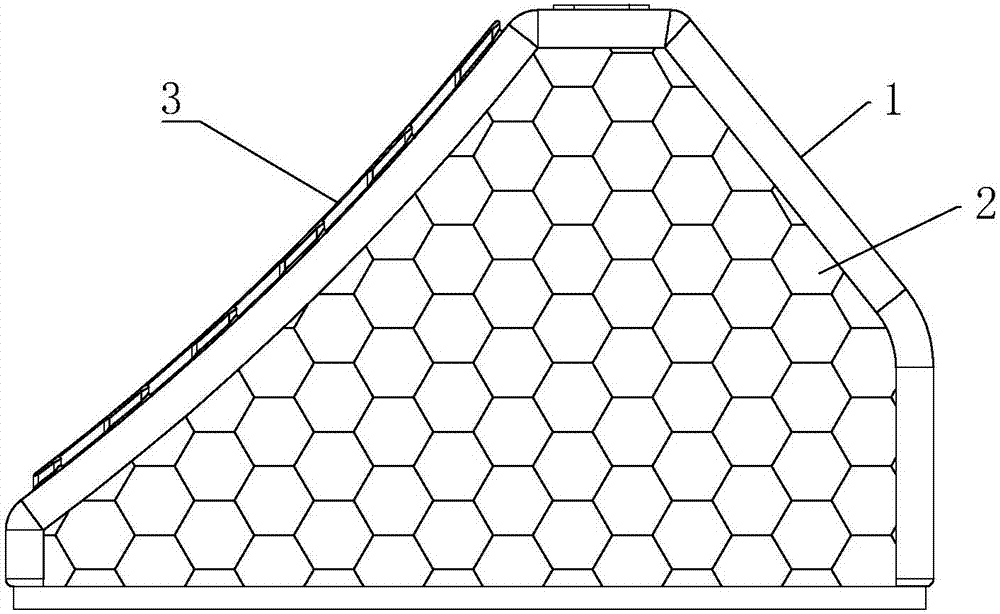

[0033] Such as figure 2 As shown, the shell 1 is made by mixing polyvinyl chloride and nitrile rubber and blow molding, and a cavity is formed inside the shell 1 . Polyurethane rigid foam 2 raw materials include polyols, isocyanates, blowing agents and modifiers. The foaming agent is liquid carbon dioxide, and the modifying agent is silicon-based mesoporous material. After the polyurethane rigid foam 2 raw material is injected into the cavity and foamed, the polyurethane rigid foam 2 located in the shell 1 is formed. ...

Embodiment 2

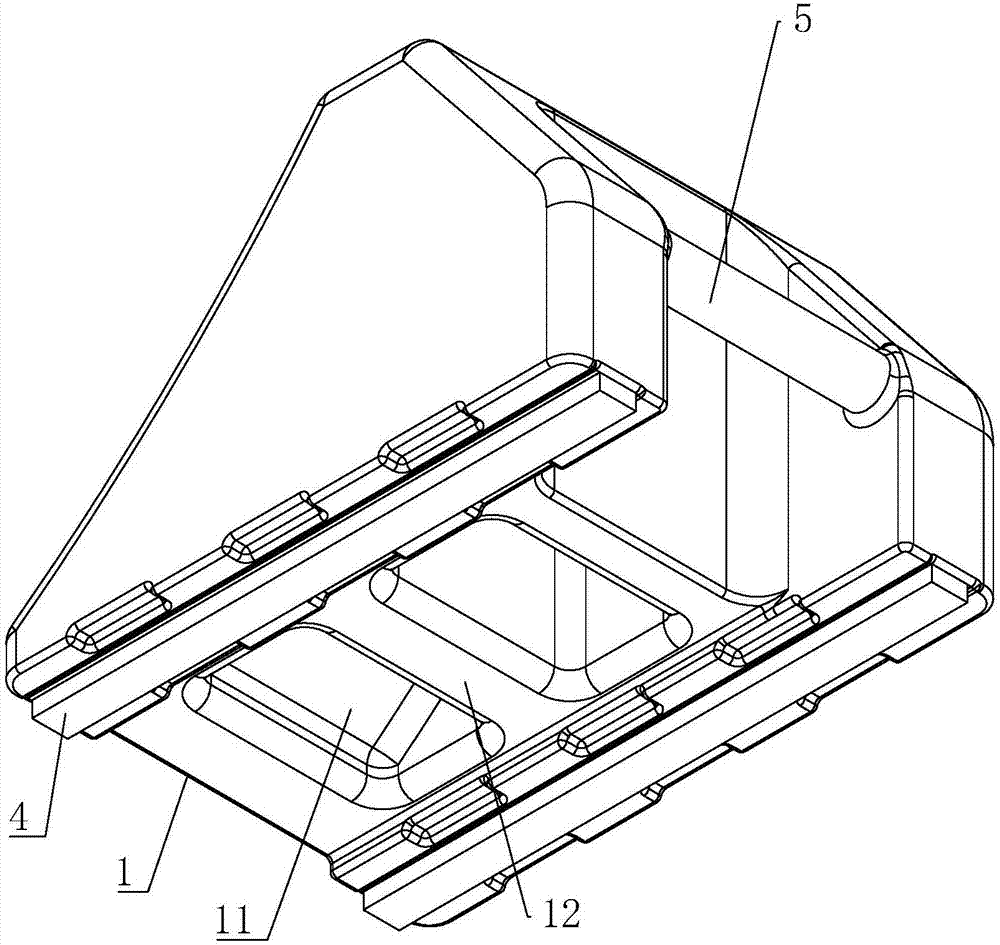

[0038] Embodiment 2: a kind of stopper, the difference with embodiment 1 is, as Figure 4 As shown, the front and rear ends of the housing 1 are provided with blocking surfaces 3 , and the gripping portion 5 is provided on the side wall of the housing 1 .

[0039] The preparation method of the modifier is as follows, step 1, weigh 2,5,8,11 tetrapinacol borate perylene monomer, 1,3,6,8-tetrabromoperylene, triphenylphosphine, cesium carbonate , cesium fluoride, bis(dibenzylidene acetone) cake (0), nano oxide, add anhydrous and oxygen-free N, N-dimethylformamide, anhydrous and oxygen-free toluene after mixing; Step 2, step The mixture of 1 was heated and refluxed for 48 hours under nitrogen system; step 3, the mixture in step 2 was cooled and then filtered to obtain a solid intermediate product, which was washed with acetone several times; step 4, using tetrahydrofuran as a solvent, using Soxhlet extraction Repeatedly extract the intermediate product in step 3 several times; ste...

Embodiment 3

[0041] Embodiment 3: A stopper. The difference from Embodiment 2 is that in the preparation process of the modifier, the nano-oxide is nano-silicon dioxide, and the parts by weight of each component are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com