A method of strengthening SBR to realize stable nitrosation by using adsorbent ammonia nitrogen material

A technology for adsorbing ammonia and stabilizing ammonia, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. It can solve the problems of reducing nitrosation rate, high energy consumption, and harsh operating conditions. Achieve the effects of high processing efficiency, low investment cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

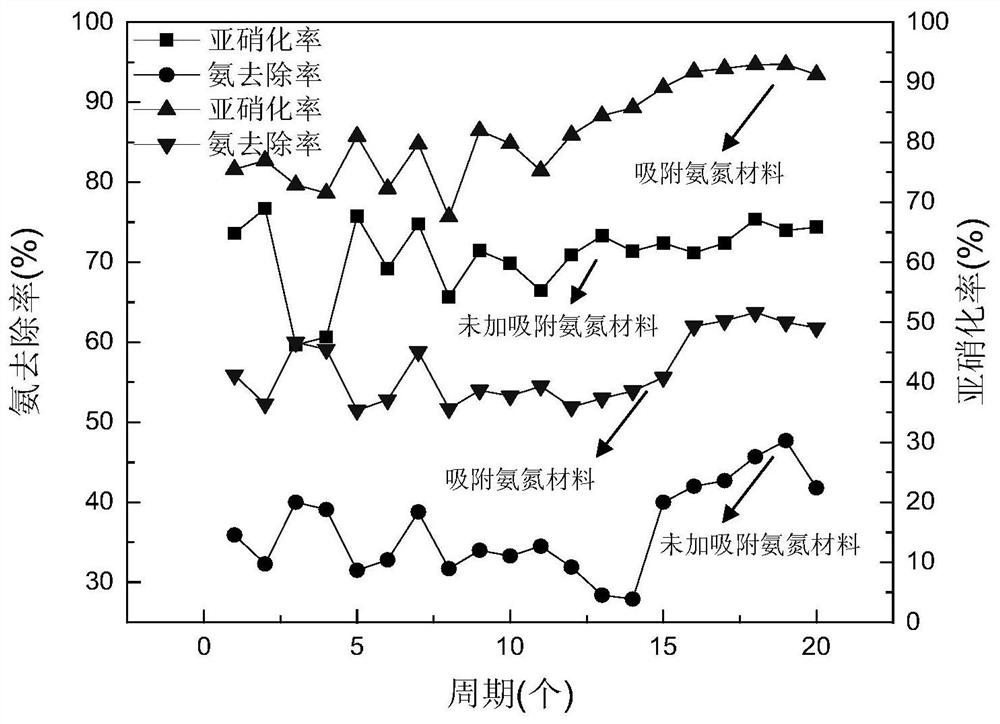

Embodiment 1

[0031] A kind of method utilizing the material of adsorbing ammonia nitrogen to strengthen SBR stable nitrosation, comprises the following steps:

[0032] (1) Inoculate the mature nitrification sludge (MLSS: 3500mg / L) into the SBR reactor (volume 5L), and then add 10g / L to the SBR reactor (add 10g of ammonia nitrogen adsorption material per 1L of ammonia nitrogen wastewater) The material for adsorbing ammonia nitrogen (artificially synthesized zeolite powder), the concentration of ammonia nitrogen in the influent water is 200mg / L, the pH of the solution in the SBR reactor is controlled to be 7.5, and the biochemical reaction is carried out at room temperature with continuous aeration (DO is controlled above 1mg / L). When more than half of the ammonia nitrogen in the wastewater is converted into nitrous nitrogen, stop the aeration, let it settle for 0.5h, and discharge part of the water in the SBR reactor (part of the water is 50% of the wastewater volume in the SBR reactor). to...

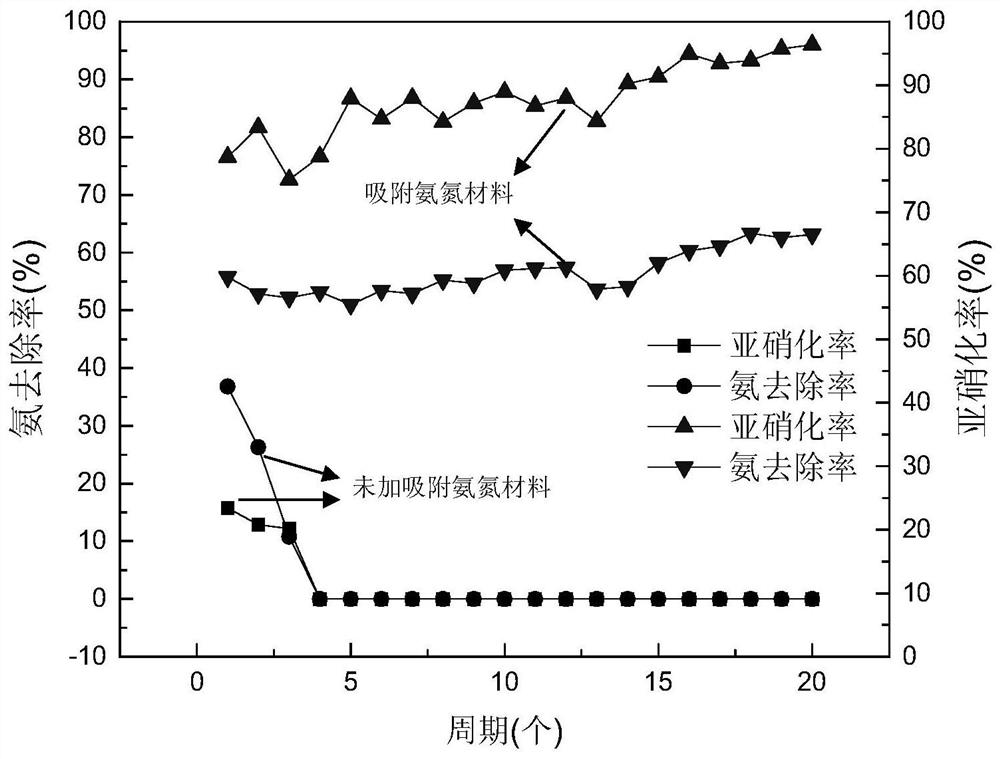

Embodiment 2

[0039] A kind of method utilizing the material of adsorbing ammonia nitrogen to strengthen SBR stable nitrosation, comprises the following steps:

[0040](1) Inoculate the mature nitrification sludge (MLSS is 3500mg / L) into the SBR reactor (volume 5L), and then add 50g / L to the SBR reactor (add 50g of ammonia nitrogen adsorption material per 1L of ammonia nitrogen wastewater) The material for adsorbing ammonia nitrogen (natural zeolite powder), the concentration of ammonia nitrogen in the influent water is 600mg / L, the pH of the solution in the SBR reactor is controlled to be 8 (sodium bicarbonate / sodium carbonate buffer solution controls the pH to be 8), continuous aeration is at room temperature Carry out biochemical reaction, DO is controlled at about 2mg / L, when half or more of the ammonia nitrogen in the wastewater is converted into nitrous nitrogen, stop the aeration, let it settle for 1.5 hours, and discharge part of the water in the SBR reactor (part of the water is 60...

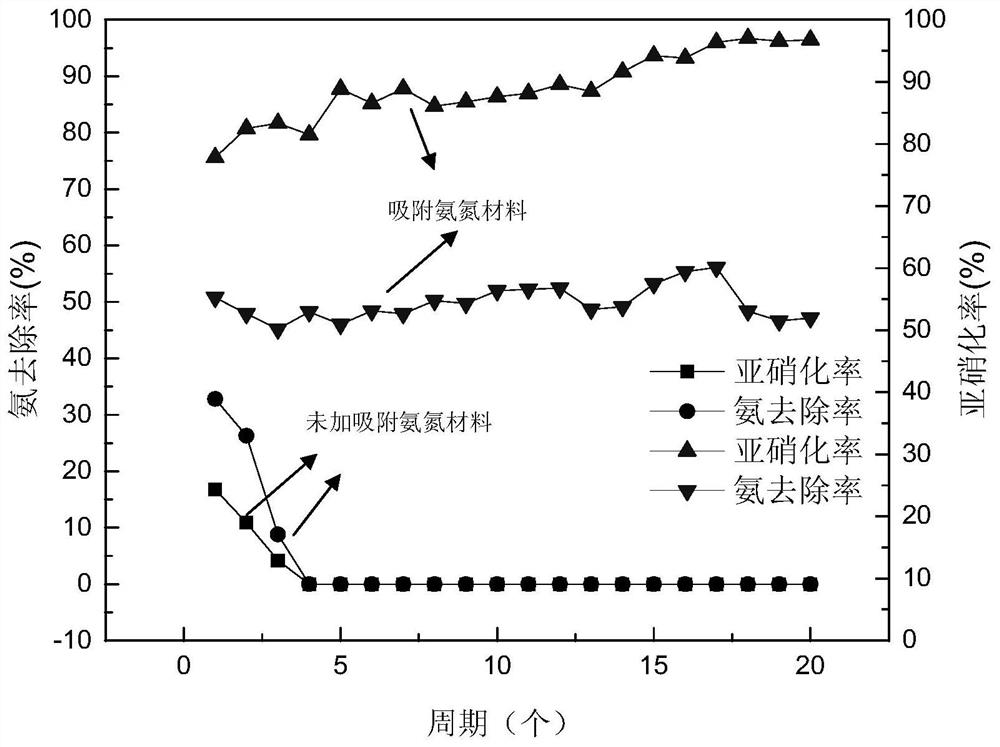

Embodiment 3

[0047] A kind of method utilizing the material of adsorbing ammonia nitrogen to strengthen SBR stable nitrosation, comprises the following steps:

[0048] (1) Inoculate the mature nitrification sludge (MLSS is 3500mg / L) into the SBR reactor (volume 5L), and then add 100g / L to the SBR reactor (add 100g of ammonia nitrogen adsorption material per 1L of ammonia nitrogen wastewater) The material for adsorbing ammonia nitrogen (natural zeolite powder), the concentration of ammonia nitrogen in the influent water is 1000mg / L, the pH of the solution in the SBR reactor is controlled to 9 (sodium bicarbonate / sodium carbonate buffer solution controls the pH to 9), continuous aeration is at room temperature Carry out biochemical reaction, DO is controlled at about 3mg / L, when half or more of the ammonia nitrogen in the wastewater is converted into nitrous nitrogen, stop the aeration, let it settle for 2 hours, and discharge part of the water in the SBR reactor (part of the water is SBR 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com