Micro-structured pressure-sensitive sensor and preparation method thereof

A pressure-sensitive sensor and microstructured technology, applied in the chemical industry, can solve the problem that the sensitivity is not comparable to that of human skin, and achieve good durability and stability, high sensitivity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 2ml of distilled water to a 25ml straight glass bottle equipped with a stopper, and seal it with a stopper until the water vapor in the bottle reaches the saturated vapor pressure. Place a plastic stand in a glass bottle saturated with water vapor, and place a clean glass substrate horizontally on top of it. PS and P123 were mixed at a ratio of 7:2 and dissolved in dichloromethane to form a mixed solution of 60 mg / ml. Using a microsampler, 100 μL of the above solution was dropped on the glass substrate, and then sealed with a stopper. With the volatilization of dichloromethane, the colorless and transparent polymer solution gradually became cloudy until it turned white, and a PS film was obtained.

[0029] Configure PDMS prepolymer (dimethylsilane prepolymer and curing agent are mixed uniformly at a mass ratio of 10:1), and then add it dropwise to the PS film, vacuum-assisted degassing and curing reaction at 70°C for 1h, and then dichloro Methane was dissolved to r...

Embodiment 2

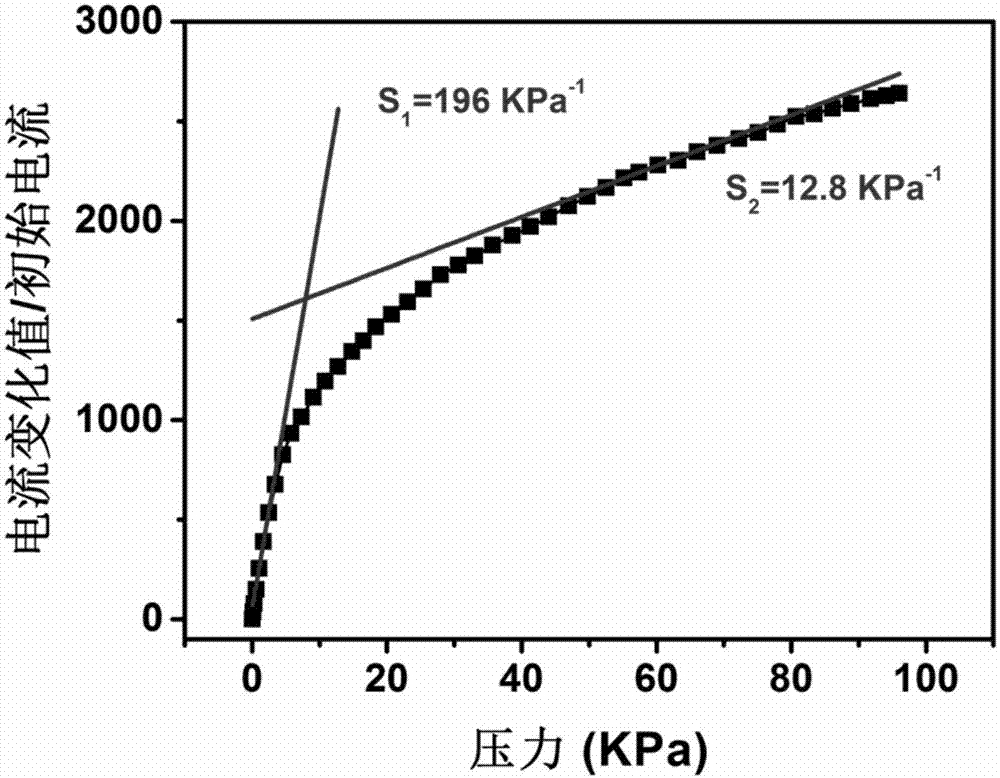

[0031] A layer of gold particles was deposited on the surface of the structured PDMS film prepared in Example 1 by magnetron ion sputtering to obtain a structured conductive film. Take two pieces of structured conductive film, coat silver paste on both ends respectively, and connect copper wire, place in 120°C oven for 30 minutes to cure the silver paste, and assemble the two hemispheres facing each other to form a pressure sensitive sensor. Use a digital dynamometer to test the pressure on the sensor. At the same time, the lower end of the dynamometer is fixed to apply a small pressure through the electric displacement console. At the same time, the wires connected to the upper and lower two films are connected to the digital source meter test system to monitor the current value under different pressures. (the output voltage is constant at 1V), the recorded pressure value (P) and the corresponding current change value (ΔI / I 0 ) is drawn as a change curve, such as figure 1 As...

Embodiment 3

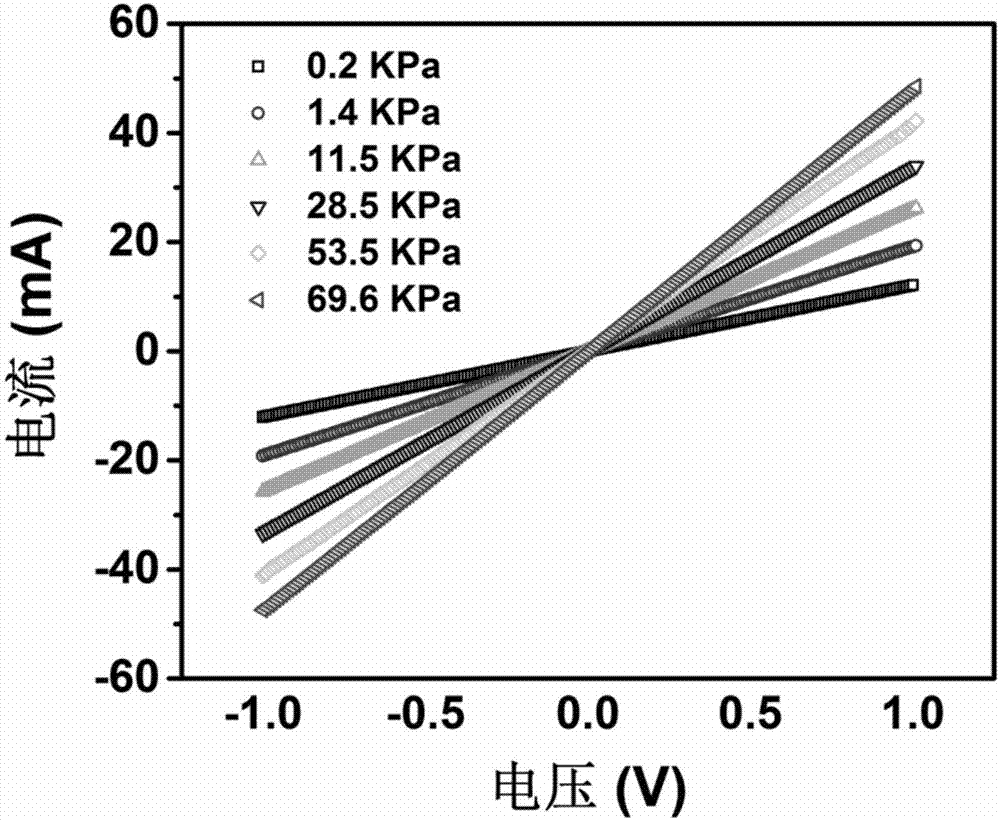

[0033] Obtain the pressure-sensitive sensor according to the method in embodiment 2, connect the digital source meter at both ends, apply different pressures in the range of 0 to 70KPa respectively, test the corresponding cyclic voltammetry curve, and draw the obtained multiple curves into I-V curves, such as figure 2 As shown, it can be seen that the I-V curve conforms to Ohm's law, and as the pressure increases, the slope increases, that is, the resistance decreases, which conforms to figure 1 changing trends in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com