Self-supporting lithium-sulfur battery cathode material with high sulfur load and preparation method of self-supporting lithium-sulfur battery cathode material

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, positive electrodes, etc., can solve the problems of difficult sulfur content and spatial distribution of shell voids, external sulfur residues, low electrical conductivity, etc., to improve infiltration. and ionic conductivity, cost reduction, and positive electrode weight reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

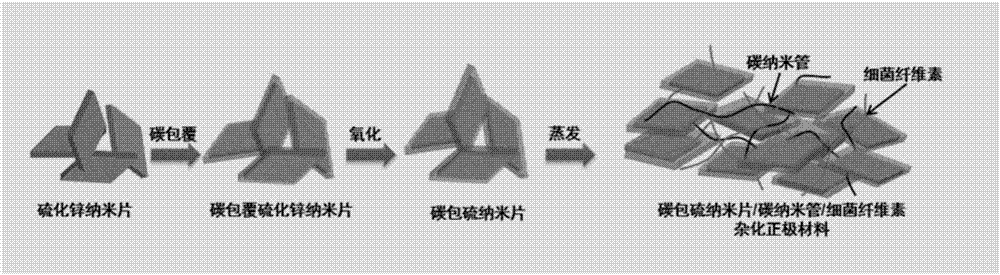

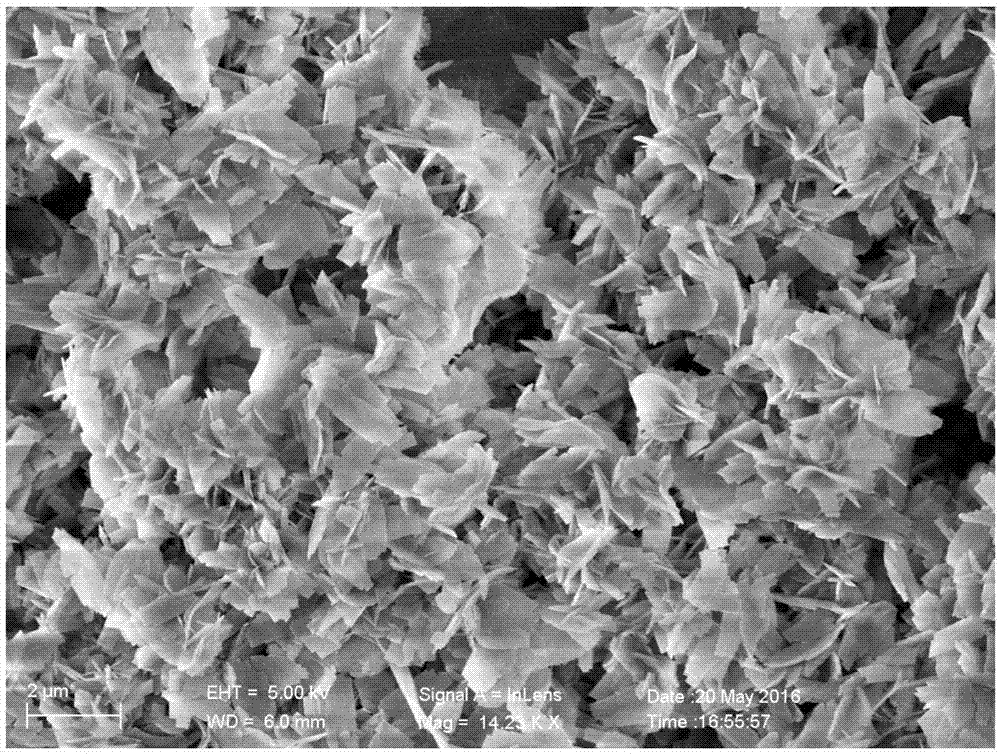

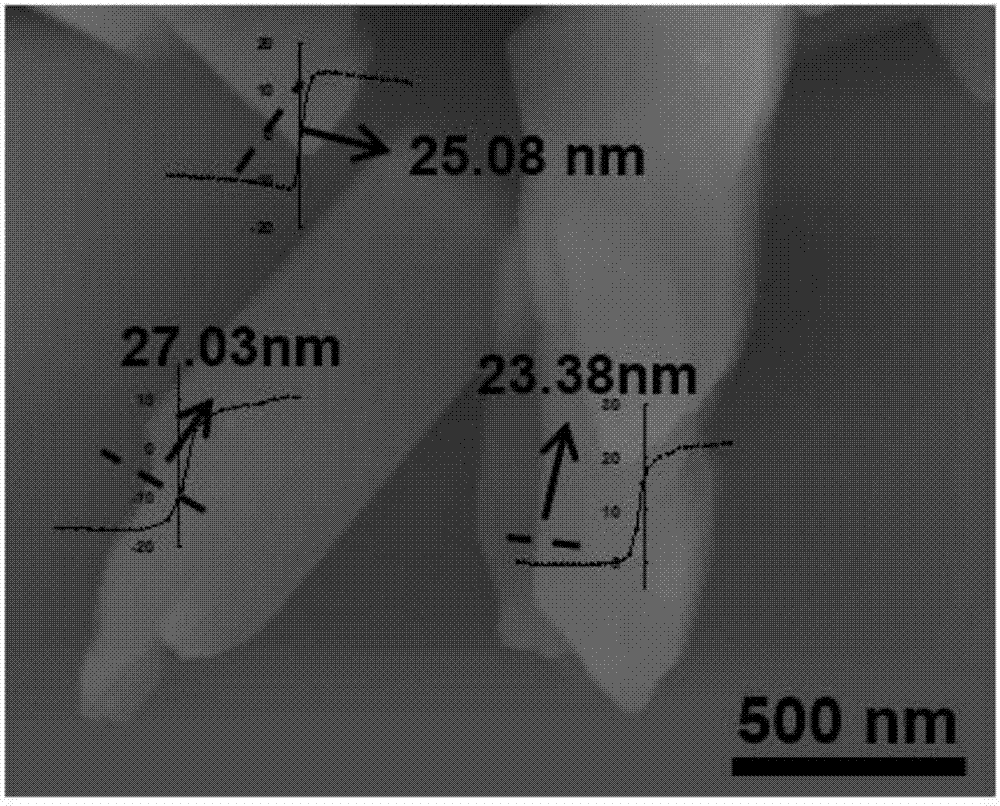

[0090] combine figure 1 Flowchart for the preparation of carbon-coated sulfur nanosheets / carbon nanotubes / bacterial cellulose hybrid positive electrode materials, first zinc sulfide (diethylenetriamine) 0.5 The hybrid nanosheets were annealed at 400°C for 2 h in an inert environment in a tube furnace to obtain the corresponding pure zinc sulfide nanosheets; then acetylene was used as the carbon source and argon was used as the carrier gas (the volume ratio of the two was 1:9), and 500 ℃ deposition for 2 hours, in-situ carbon coating by chemical vapor deposition, and further treatment at 900 °C for 2 hours under inert gas conditions to further improve the conductivity and stability of the carbon layer, and the desired carbon-coated zinc sulfide nanosheets were obtained; take 300mg Add carbon-coated zinc sulfide nanosheets into a centrifuge tube, add 30ml of water and ultrasonically shake until uniformly dispersed, then transfer it to a 500ml beaker, place it in an ice bath and ...

Embodiment 2

[0093] The difference between this embodiment and the specific example 1 is that the chemical vapor deposition temperature is changed to 600° C., and the time is changed to 3 hours.

Embodiment 3

[0095] The difference between this embodiment and specific example 1 is that ferric nitrate nonahydrate is changed to anhydrous ferric chloride, and the molar content is 0.125 mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap