Excimer laser polishing and detection method of porous ceramics

An excimer laser, porous ceramic technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of reducing the recognition degree of the outer part of the porous ceramic surface pores, and the limited detection degree of the convex part of the ceramic surface, reaching the Improve recognition and accuracy, reduce the impact of detection, and the effect of large laser single photon energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for excimer laser polishing of porous ceramics, comprising the steps of:

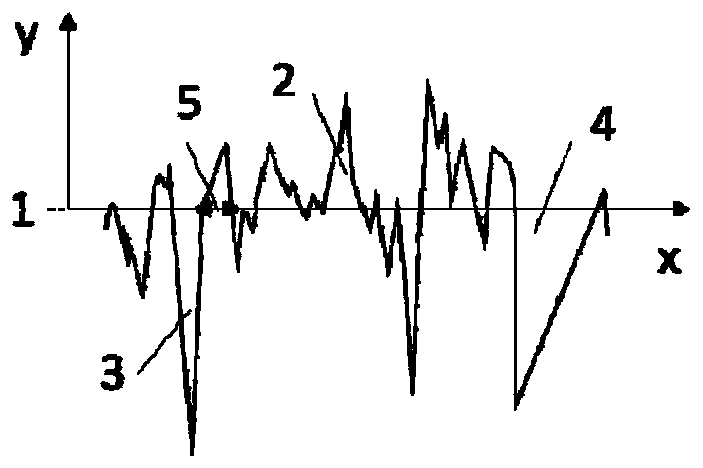

[0032] ① if figure 1 As shown, use the Zygo surface roughness analysis equipment to scan the contour of the SiC porous ceramic surface to be processed, and use it as a reference line (1) Divide a certain length of contour into two parts, so that the distance between the baseline and the lower part of the contour line and the reference line The included areas are equal, the upper part is defined as the peak value (2), and the lower part is the valley value (3). The average pore size (4) of the porous ceramic surface is measured to be about 15 μm, and the pore spacing (5) is about 50 μm.

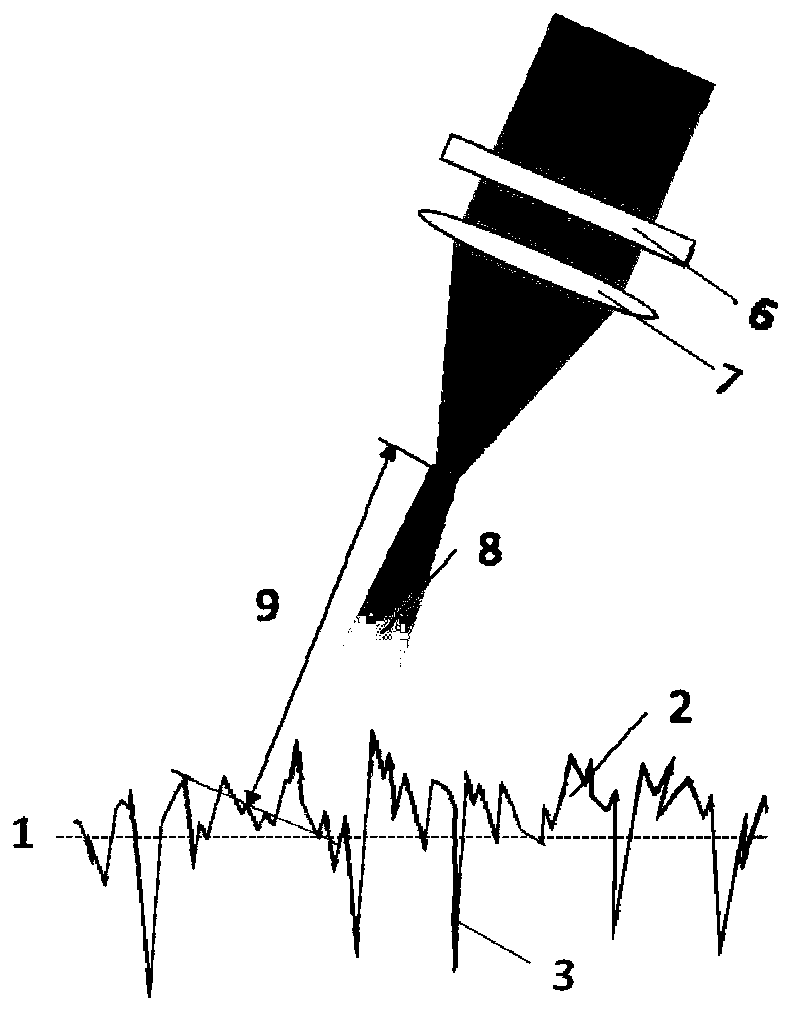

[0033] ② if figure 2 As shown, the ArF excimer laser beam is sequentially passed through the beam homogenizer (6) and the focusing lens (7) to realize the focusing and homogenization of the laser beam to obtain a uniform beam (8). According to the pore size (4) and pore size of the porous ceramic The ...

Embodiment 2

[0037] On the basis of above-mentioned embodiment 1, also disclose a kind of roughness detection method before and after the excimer laser polishing of porous ceramics, comprise the step ①-④ in embodiment 1, also comprise following steps in addition:

[0038] ⑤Analyze the profile of the porous SiC ceramic surface to be processed obtained by scanning in step ①, record the average distance between the baseline (1) and the valley (3), and use the formula The surface convex roughness r=ra=0.96 μm of porous SiC ceramics before polishing was calculated.

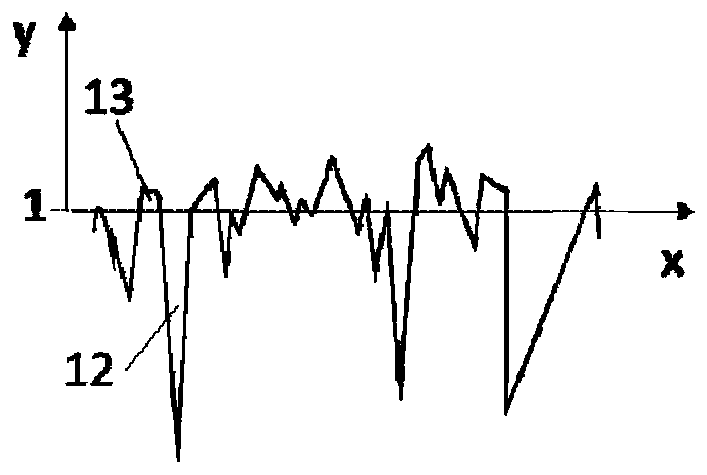

[0039] ⑥ Use the Zygo surface roughness analysis equipment to scan the surface profile of porous SiC ceramics after polishing, such as image 3 As shown, the average distance between the baseline (1) and the valley (12) is the average distance before polishing, which is approximately 0.96 μm in the experiment. According to the peak (13) area of the surface profile above the reference line, the projected roughness of the porous Si...

Embodiment 3

[0041] A roughness detection method before and after polishing of porous ceramics, comprising the following steps:

[0042] S1 analyzes the surface profile of porous ceramics before polishing, takes the reference line as the x-axis, establishes a rectangular coordinate system perpendicular to the reference line as the y-axis, and records the average distance y between the reference line and the valley 0 , to calculate the surface convex roughness of porous ceramics before polishing Where l is the sampling length, and y is the distance between the contour above the baseline and the baseline;

[0043] S2 analyzes the surface profile of porous ceramics after polishing, and makes a reference line so that the average distance from the valley is y 0 +y', where y' is the change value of the pore depth before and after polishing, and y' is approximately 0 when the incident angle is large; according to the peak area and sampling length of the porous ceramic surface profile above the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com