Totally-inorganic halide perovskite material CsPbI3 nanotube, and preparation method and application thereof

A halide perovskite and nanotube technology, applied in the direction of inorganic chemistry, chemical instruments and methods, lead compounds, etc., can solve the problems that have not been reported, and achieve the effect of uniform shape, wide source of raw materials, and rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Mix 0.2g CsCO3, 0.6ml oleic acid, and 10ml octadecene into a three-necked flask and dry at 120°C for 1 hour, then heat up to dissolve CsCO3 to obtain a Cs-oleate solution;

[0035] (2) 0.348g PbI 2 Add to 20mL octadecene and dry at 120°C, add 2ml oleic acid and 2ml oleylamine (joint action) to dissolve PbI 2 Then be warming up to 150 ℃, add the Cs-oleic acid salt solution 1.6mL that step (1) obtains and carry out quick reaction 10 seconds, stop reaction immediately with ice bath then, cooling, obtains CsPbI 3 Nanocrystalline solution;

[0036] (3) CsPbI 3 The nanocrystal solution was transferred to a microwave quartz tube for microwave reaction at a reaction temperature of 130°C for 30 minutes; the reaction product was centrifuged at low speed and washed with n-hexane to obtain CsPbI 3 nanotube.

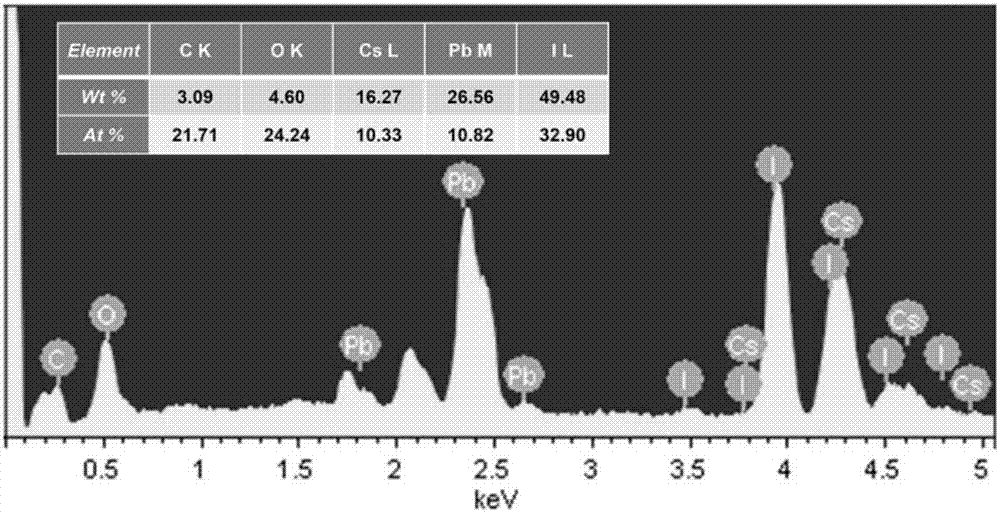

[0037] The CsPbI prepared in this embodiment 3 The molar ratio of Cs:Pb:I in nanotubes is 1:1:3.

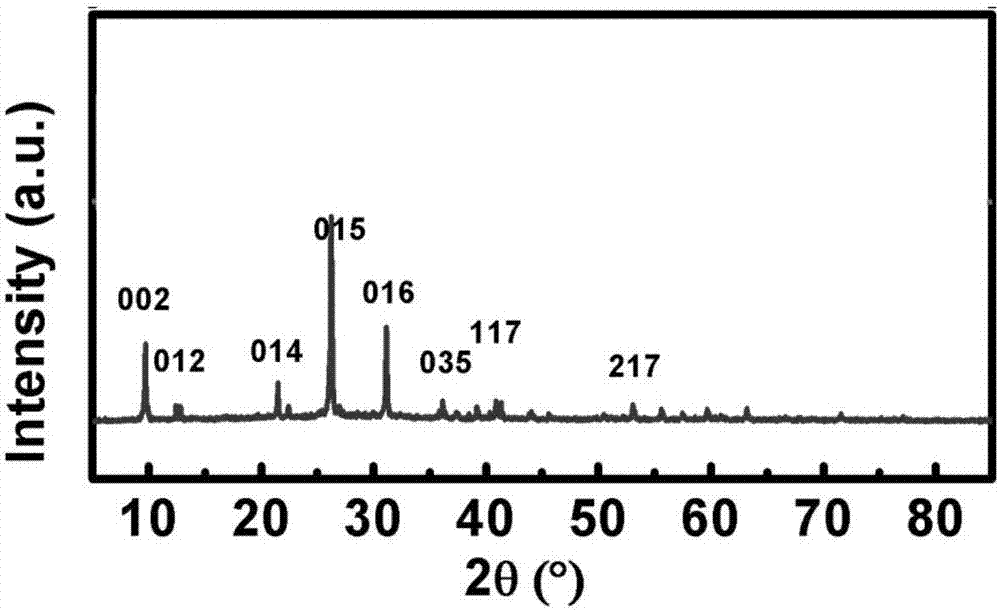

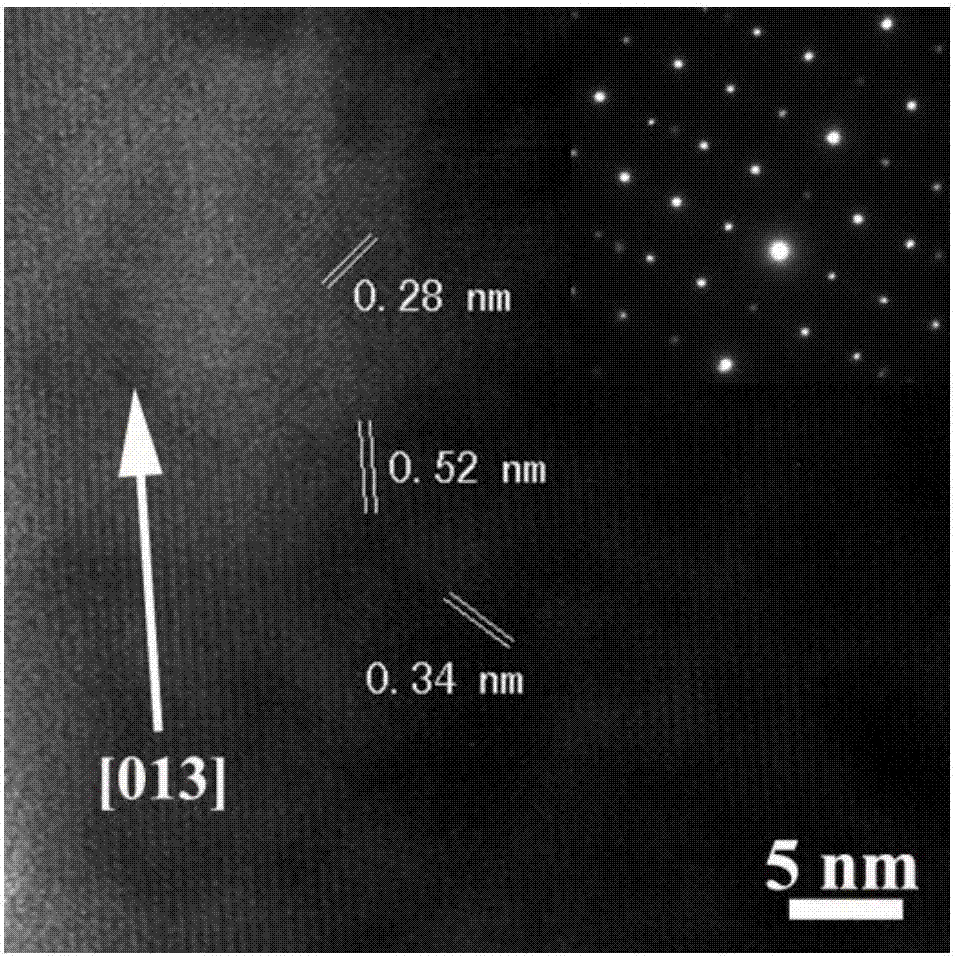

[0038] The CsPbI prepared in this embodiment 3 The X-ray diffract...

Embodiment 2

[0047] Prepare CsPbI by the same raw material and steps of Example 1 3 Nanotubes, the difference is that the microwave reaction temperature is changed to 110°C, and the scanning electron microscope image of the implementation results is as follows Figure 9 As shown, CsPbI 3 Nanotubes have a high purity, uniform structure, but a narrow width.

Embodiment 3

[0049] Prepare CsPbI by the same raw material and steps of Example 1 3 Nanotubes, the difference is that the microwave reaction time is 15 minutes, the scanning electron microscope picture of the implementation result is as follows Figure 10 As shown, the average length of nanotubes is shorter than that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com