Preparation method of viscosity-reducing type polycarboxylic acid water reducer

A technology of viscous polycarboxylate and water reducing agent, which is applied in the field of construction admixtures, can solve problems such as limited slump retention capacity, inability to realize low temperature energy saving, and inability to achieve high-strength concrete, so as to improve construction performance and reduce the thickness of Stem layer , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

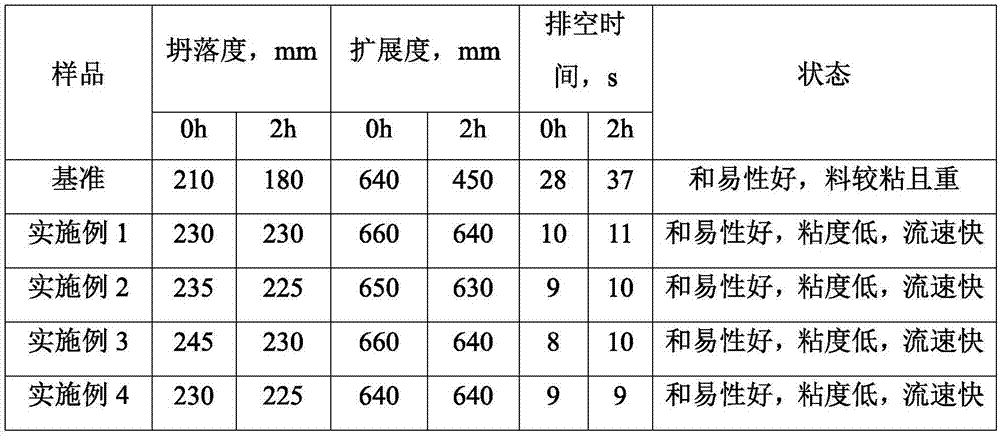

Examples

Embodiment 1

[0026] (1) Adding 300 parts by weight of molecular weight in the reactor is 4-hydroxybutyl vinyl polyoxyethylene ether of 3000, 2 parts by weight of concentration is the phosphoric acid of 85% and the phosphorus pentoxide of 5 parts by weight, at 40 ℃ After reacting for 3 hours, 4-hydroxybutyl vinyl polyoxyethylene phosphate can be obtained.

[0027] (2) Then, add 300 parts by weight of water into the reactor, stir to dissolve, add 10 parts by weight of acrylic acid, and the pH value is 4.3.

[0028] (3) The temperature is at 15°C, and 5 parts by weight of hydrogen peroxide solution is added to the material obtained in step (2) at one time, and fully stirred;

[0029] (4) in the material of step (3) gained, drop respectively the acrylic acid of 15 weight parts, the mixing of the 4-vinylaniline of 3 weight parts, the trifluoroethyl acrylate of 3 weight parts and the trisodium phosphate of 3 weight parts solution and 1 part by weight of Brüggolit TM FF6 aqueous solution, dripp...

Embodiment 2

[0031] (1) Adding 400 parts by weight molecular weight is 4-hydroxybutyl vinyl polyoxyethylene base ether of 4000, 2 parts by weight concentration is the phosphoric acid of 85% and the phosphorus pentoxide of 5 parts by weight in reactor, at 40 ℃ After reacting for 3 hours, 4-hydroxybutyl vinyl polyoxyethylene phosphate can be obtained.

[0032] (2) Then, add 400 parts by weight of water into the reactor, stir and dissolve, add 12 parts by weight of methacrylic acid, and the pH value is 4.5.

[0033] (3) temperature is at 20 ℃, in the material of step (2) gained, disposablely add the ammonium persulfate solution of 4 parts by weight, and fully stir;

[0034] (4) Add 13 parts by weight of methacrylic acid dropwise, 3 parts by weight of 3-vinylbenzoic acid, 4 parts by weight of methacrylic acid 2,2,2-trifluoroethyl ether in the material obtained in step (3). The mixed solution of ester and 2 parts by weight of thioglycolic acid and 1.5 parts by weight of dipotassium 2-hydroxyl-...

Embodiment 3

[0036] (1) Adding 500 parts by weight molecular weight is 5000 4-hydroxybutyl vinyl polyoxyethylene ether, 2 parts by weight concentration of 85% phosphoric acid and 5 parts by weight phosphorus pentoxide in the reactor, at 40 ℃ After reacting for 3 hours, 4-hydroxybutyl vinyl polyoxyethylene phosphate can be obtained.

[0037] (2) Then, add 500 parts by weight of water into the reactor, stir to dissolve, add 8 parts by weight of itaconic acid, and the pH value is 4.8.

[0038] (3) The temperature is at 25°C, and 3 parts by weight of hydrogen peroxide solution is added to the material obtained in step (2) at one time, and fully stirred;

[0039] (4) Add 15 parts by weight of itaconic acid dropwise to the material obtained in step (3), 4-vinylbenzylamine of 5 parts by weight, 2,2,2-trifluoroethyl methacrylic acid of 6 parts by weight The mixed solution of ester and 3 parts by weight of mercaptoethanol and the aqueous solution of ascorbic acid of 1 part by weight are dropped in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com