Industrial sludge, waste emulsion slag and metallurgical ash joint treatment system and power generation process thereof

A technology for industrial sludge and waste emulsion, which is applied in joint combustion mitigation, chemical instruments and methods, incinerators, etc., can solve the problem of low efficiency of boiler dusty waste gas treatment, pollution of soil, water quality, and easy generation of odor, etc. problem, to achieve the effect of stable properties, low viscosity and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

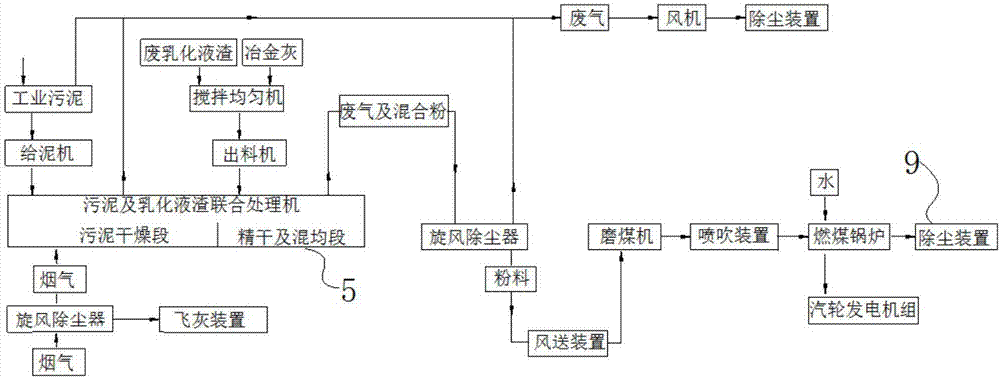

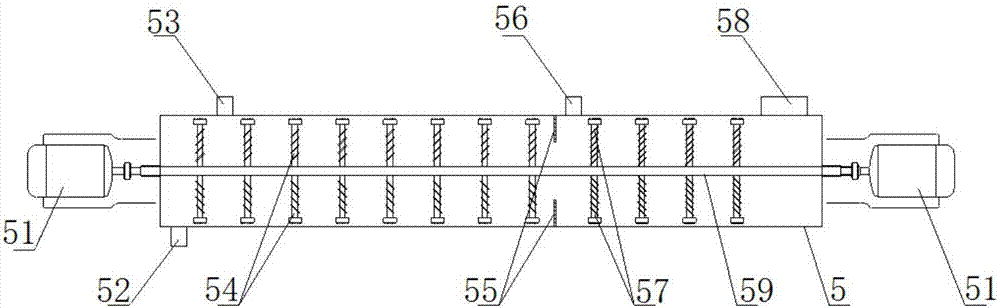

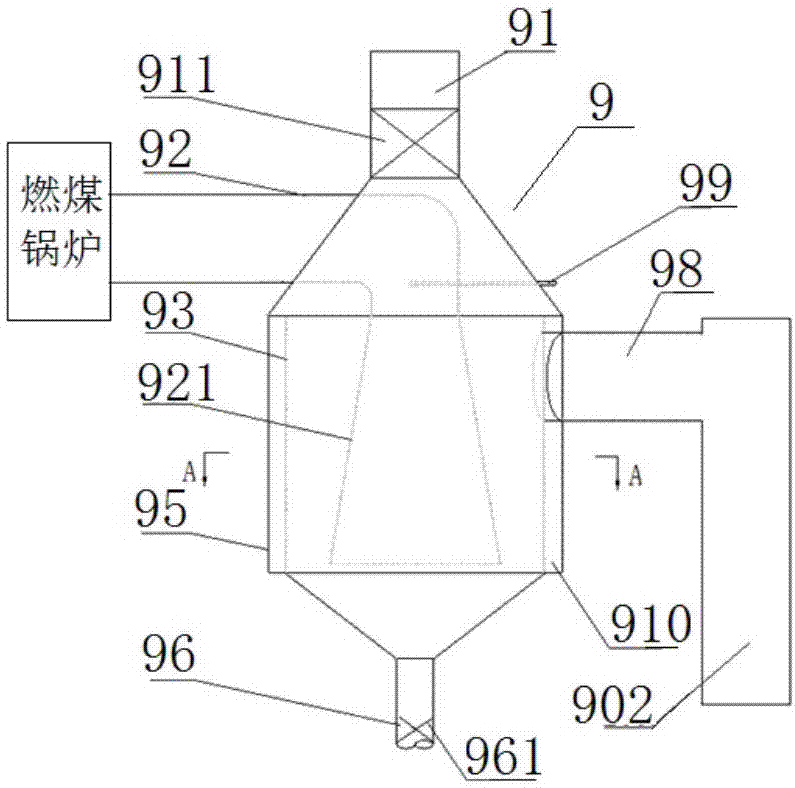

[0051] A combined treatment system for industrial sludge, waste emulsion slag and metallurgical ash in this embodiment, such as figure 1 As shown, it includes a mud feeder, a mixer, a discharger, an air delivery device, a coal mill, an injection device, a coal-fired boiler and a steam turbine generator set, and also includes a sludge and emulsified liquid slag joint processor 5 and Dust removal device 9, such as figure 2 As shown, the sludge and emulsified liquid slag joint processor 5 has a horizontal barrel-like structure as a whole, including a drive shaft 59 that runs through the center line of the barrel body. A scraper spiral agitator is fixedly connected around the shaft 59, and the barrel body is provided with a sludge inlet 53, a high-temperature flue gas inlet 52, an emulsion slag inlet 56 and a discharge outlet 58, wherein: the sludge feeder transfers industrial sludge The high-temperature flue gas for heating is passed into the barrel through the high-temperature...

Embodiment 2

[0054] A combined treatment system for industrial sludge, waste emulsion slag and metallurgical ash in this embodiment has the same basic structure as in Embodiment 1, the difference and improvement are: it also includes two cyclone dust collectors, which are respectively cyclone dust collector one and Cyclone dust collector 2; cyclone dust collector 1 is installed at the high-temperature flue gas inlet 52. The high-temperature flue gas for heating is first processed by the cyclone dust collector and then passed into the barrel. The high-temperature flue gas after dust removal directly contacts the material to avoid dust. interference, high heating efficiency; the second cyclone dust collector is arranged at the discharge outlet 58, and the waste gas and the mixture discharged from the discharge outlet 58 pass through the powder treated by the second cyclone dust collector and then communicate with the air delivery device through the pipeline, and the waste gas and the mixture ...

Embodiment 3

[0064] A combined treatment system for industrial sludge, waste emulsion slag and metallurgical ash in this embodiment has the same basic structure as in Embodiment 2, the difference and improvement is that the industrial sludge is temporarily stored in a sealed industrial sludge storage The odor of the sludge storage, the sludge and emulsion slag joint processor 5 and the waste gas of the cyclone dust collector 2 are all passed through the pipeline into the dust removal device 9 for treatment and then discharged into the atmosphere; the sludge and emulsion slag joint processor 5 Negative pressure inside to avoid leakage of odor and pollute the environment. The sludge and emulsified liquid slag joint processor 5 is divided into two sections, the front section is the sludge drying section, the rear section is the fine drying and mixing section, and a swirl plate 55 is arranged between the two sections, and the scraper screw agitator in the front section is the coarse Toothed sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com