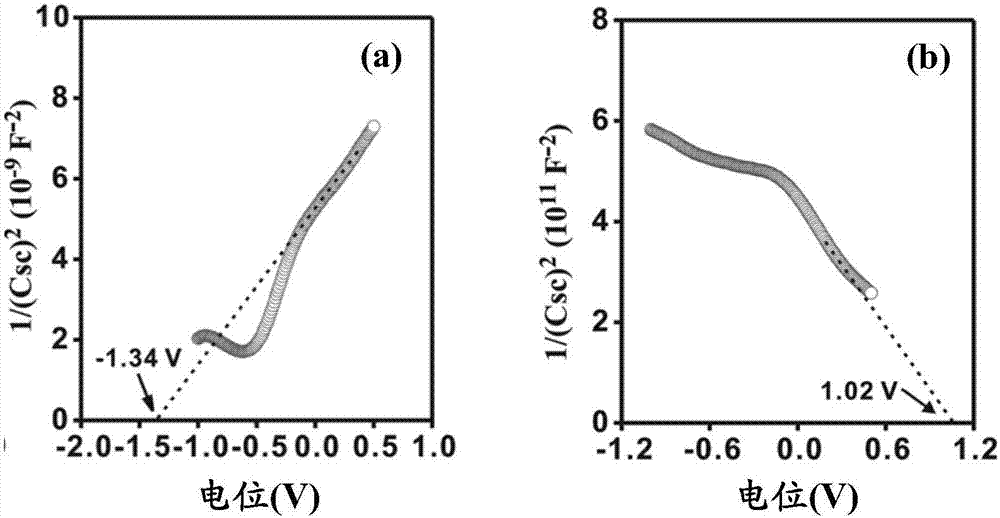

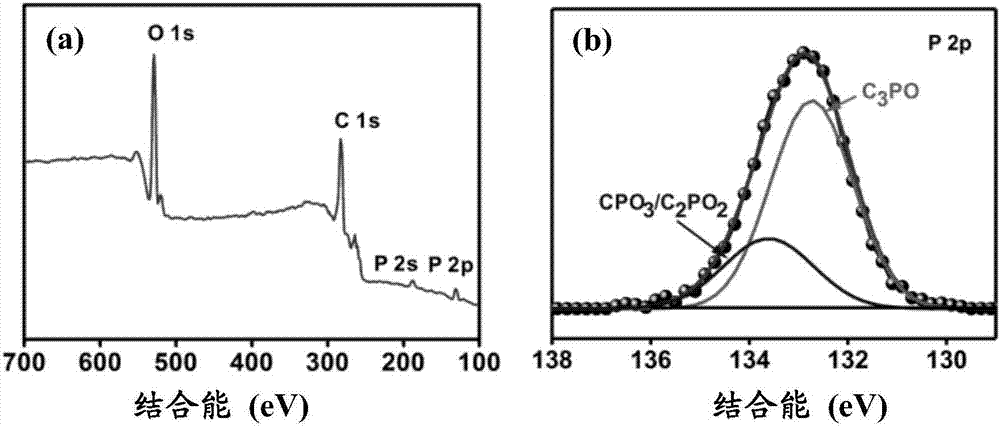

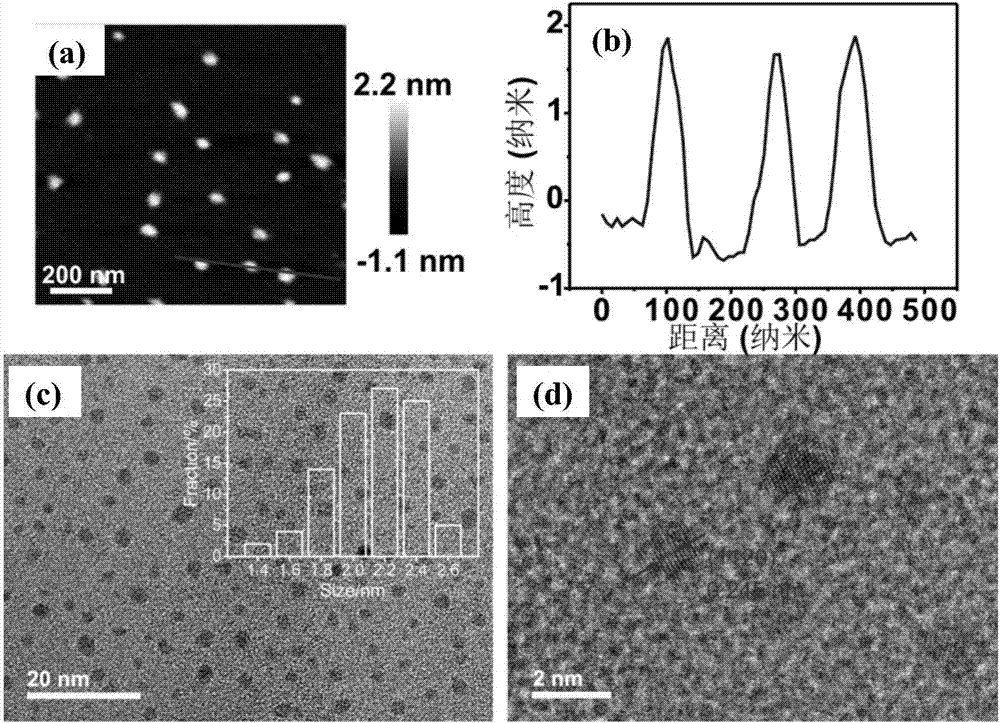

Phosphorus-doped graphene quantum dot-graphite phase carbon nitride p-n junction photocatalyst as well as preparation method and application thereof

A technology of graphene quantum dots and graphitic carbon nitride, which is applied in the field of photocatalysis and achieves the effects of simple preparation method, uniform particle size and structure, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036](1) Preparation of phosphorus-doped graphene quantum dots:

[0037] 1,3,6-Trinitropyrene and Na 2 HPO 4 12H 2 O is dissolved in water to obtain a mixed aqueous solution, adding sodium hydroxide, and performing a one-step hydrothermal reaction under alkaline conditions, wherein the concentration of 1,3,6-trinitropyrene is 2 mg / mL, Na 2 HPO 4 12H 2 The concentration of O is 70 mg / mL, the concentration of sodium hydroxide is 0.3 mol / L, the temperature of hydrothermal reaction is 200 ℃, and the time of hydrothermal reaction is 6 hours. Phosphorus-doped graphite is obtained after removing unreacted small molecules by dialysis ene quantum dots.

[0038] (2) Preparation of phosphorus-doped graphene quantum dots-graphite phase carbon nitride p-n junction photocatalyst:

[0039] The graphite phase carbon nitride powder is ultrasonically dispersed in a phosphorus-doped graphene quantum dot aqueous solution with a concentration of 11mg / mL, and the concentration of the graphit...

Embodiment 2

[0055] (1) Preparation of phosphorus-doped graphene quantum dots:

[0056] 1,3,6-Trinitropyrene and Na 2 HPO 4 12H 2 O is dissolved in water to obtain a mixed aqueous solution, adding sodium hydroxide, and performing a one-step hydrothermal reaction under alkaline conditions, wherein the concentration of 1,3,6-trinitropyrene is 5 mg / mL, Na 2 HPO 4 12H 2 The concentration of O is 50 mg / mL, the concentration of sodium hydroxide is 0.2 mol / L, the temperature of hydrothermal reaction is 180 °C, and the time of hydrothermal reaction is 10 hours. Phosphorus-doped graphite is obtained after removing unreacted small molecules by dialysis ene quantum dots.

[0057] (2) Preparation of phosphorus-doped graphene quantum dots-graphite phase carbon nitride p-n junction photocatalyst:

[0058] The graphite phase carbon nitride powder is ultrasonically dispersed in a phosphorus-doped graphene quantum dot aqueous solution with a concentration of 15mg / mL, and the concentration of the grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com