A kind of supported oxidative esterification catalyst and its preparation method and application

A technology of oxidative esterification and catalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, carboxylate preparation, etc., which can solve the problem of high palladium content, failure to meet market demand, and low efficiency and other issues, to achieve the effects of structural stability, good cycle stability, catalytic activity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

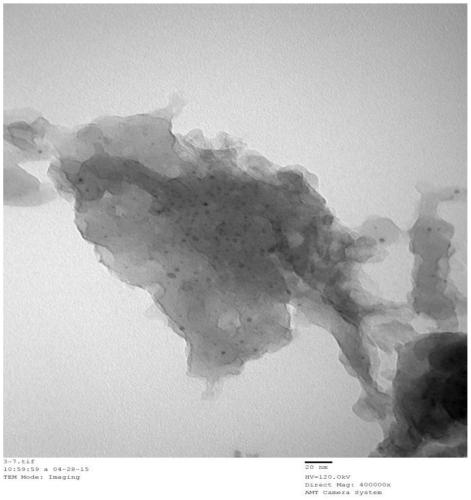

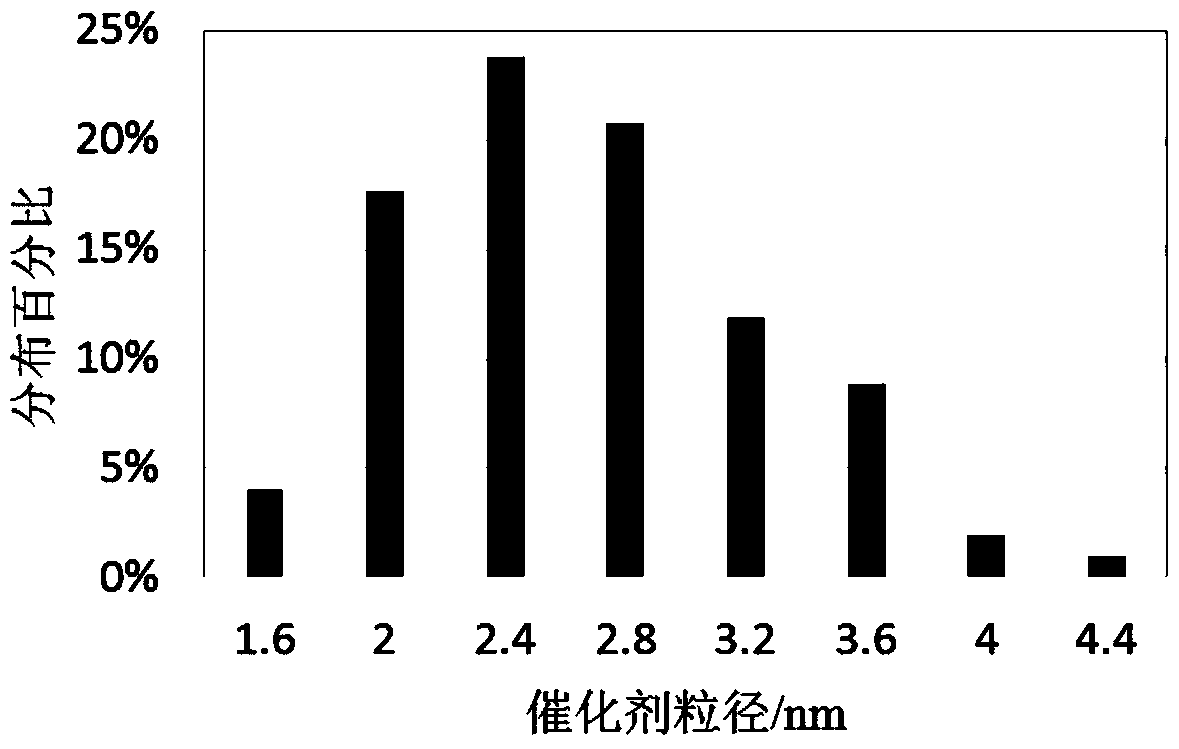

[0036] Preparation of catalyst:

[0037] Mix 3g of 200-300 mesh column chromatography silica gel, 3.0g of aluminum nitrate, 1.96g of magnesium hydroxide, 3g of concentrated nitric acid with a concentration of 65%, and 60mL of deionized water at 25°C, and keep the mixture at 50°C for 24h with stirring to obtain The homogeneous solid solution suspension was evaporated to remove water, and dried under vacuum at 80°C to obtain a white powdery solid. The solid was placed in a tube furnace and roasted under a nitrogen gas temperature program. Starting at 30°C, the temperature was raised to 300°C at a rate of 2.25°C / min, kept at 300°C for 4 hours, and then started at 300°C, and the temperature was raised at a rate of 2.5°C / min. To 600°C, keep at 600°C for 4h. SiO obtained after natural cooling 2 -MgO-Al 2 o 3 Metal composite oxide carrier, in which magnesium oxide, silicon oxide and aluminum oxide in the composite oxide carrier combine to form a solid solution, which improves the...

Embodiment 2

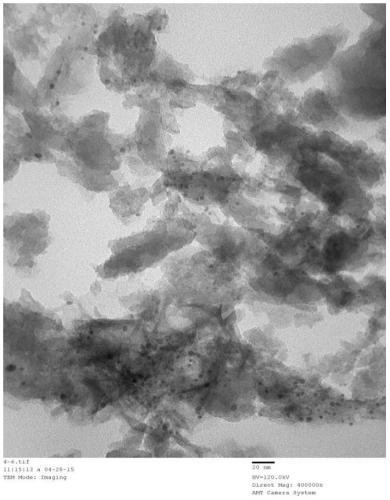

[0042] Mix 3g of 200-300 mesh column chromatography silica gel, 3.0g of calcium nitrate, 1.96g of magnesium hydroxide, 3g of concentrated nitric acid with a concentration of 80%, and 60mL of deionized water at 25°C, and keep the mixture at 50°C for 24h with stirring to obtain The homogeneous solid solution suspension was evaporated to remove water, and dried under vacuum at 80°C to obtain a white powdery solid. Put the solid in a tube furnace, and roast it under nitrogen with programmed temperature rise, heating at 30-300°C for 3 hours (heating rate 1.5°C / min), keeping at 300°C for 4 hours, heating at 300-600°C for 3 hours (heating rate 1.7°C / min) , keep at 600°C for 4h. SiO obtained after natural cooling 2 - MgO-CaO metal composite oxide support.

[0043] Add 1 g of SiO to the reactor sequentially 2 -MgO-CaO carrier, 1.6g of hexamethyltetramine, 63.5mg of chloroauric acid, 0.18g of cobalt nitrate, 0.050g of cerium nitrate, and 200mL of deionized water were mixed evenly, st...

Embodiment 3

[0046] Mix 3g of 200-300 mesh column chromatography silica gel, 5g of magnesium nitrate, 3g of concentrated nitric acid with a mass concentration of 60%, and 80mL of deionized water, and keep the mixture at 50°C for 24 hours with stirring to obtain a uniform solid solution suspension. °C and dried under vacuum to obtain a white powdery solid. Put the solid in a tube furnace, and roast it under nitrogen with programmed temperature rise, heating at 30-300°C for 3 hours (heating rate 1.5°C / min), keeping at 300°C for 4 hours, heating at 300-600°C for 3 hours (heating rate 1.7°C / min) , keep at 600°C for 4h. SiO obtained after natural cooling 2 - MgO metal composite oxide support.

[0047] Add 1 g of SiO to the reactor sequentially 2 - MgO carrier, 2.0g hexamethyltetramine, 63.5mg chloroauric acid, 0.18g cobalt nitrate, 0.03g ytterbium nitrate, 70mL deionized water were mixed evenly, stirred and reacted at 80°C for 4h, after the mixture was cooled to room temperature, Press filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com