Molybdenum disulfide quantum dot modified graphite-like carbon nitrene as well as preparation method and application thereof

A technology of molybdenum disulfide and quantum dots, applied in the field of nanomaterials, can solve the problems of unreported photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

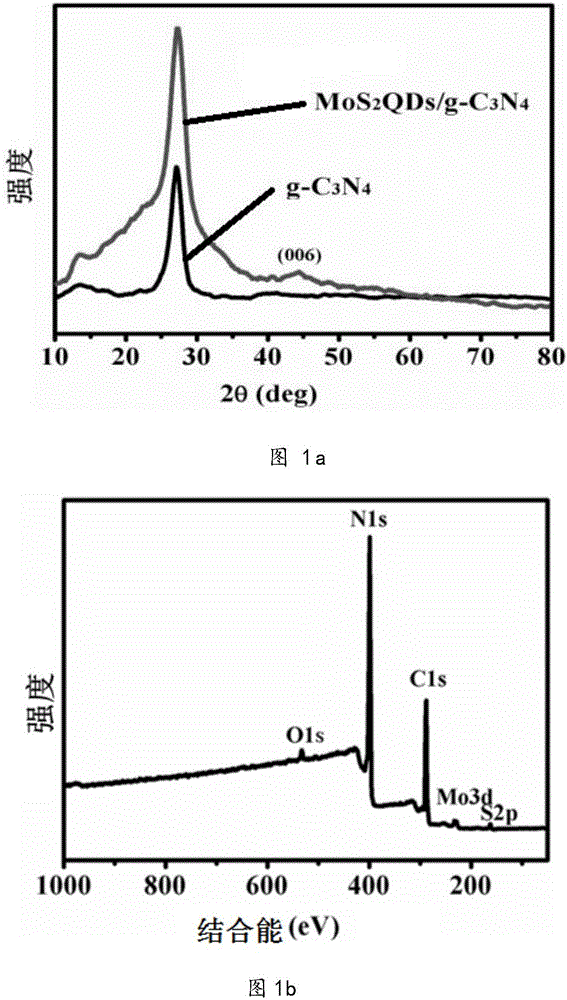

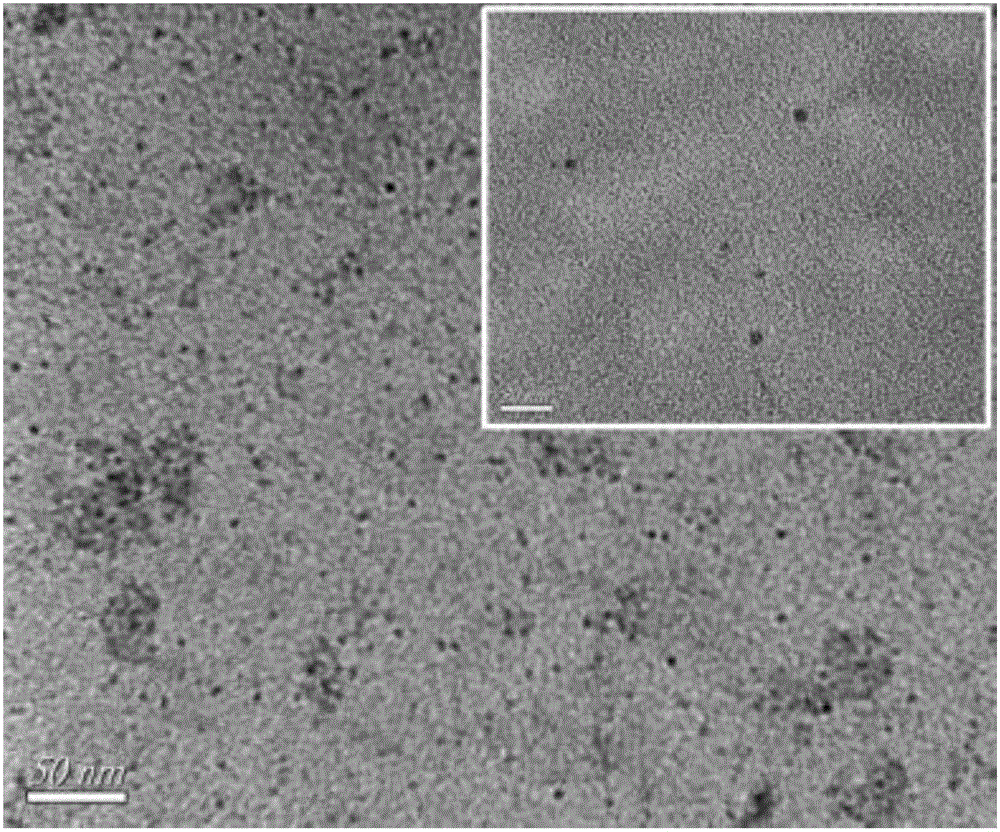

[0024] The preparation method of molybdenum disulfide quantum dot modified graphitic carbon nitrogen, comprises the steps:

[0025] (1) Add 0.22g (NH4) 2 MoO 4 and 0.4g CH 4 N 2 Dissolve S in 40 mL of deionized water, and add 1.5 mL of N 2 h 4 , after completely dissolving, continue to stir for 30 min, then transfer the mixture to a 50 mL stainless steel reaction kettle, place it in a vacuum oven at 260°C for 9 h, and cool to room temperature. After centrifugation, the reaction product was washed repeatedly with deionized water and absolute ethanol, and finally dried at 80°C for 10 h under vacuum to obtain a gray-black product powder, namely molybdenum disulfide quantum dots (MoS 2 QDs).

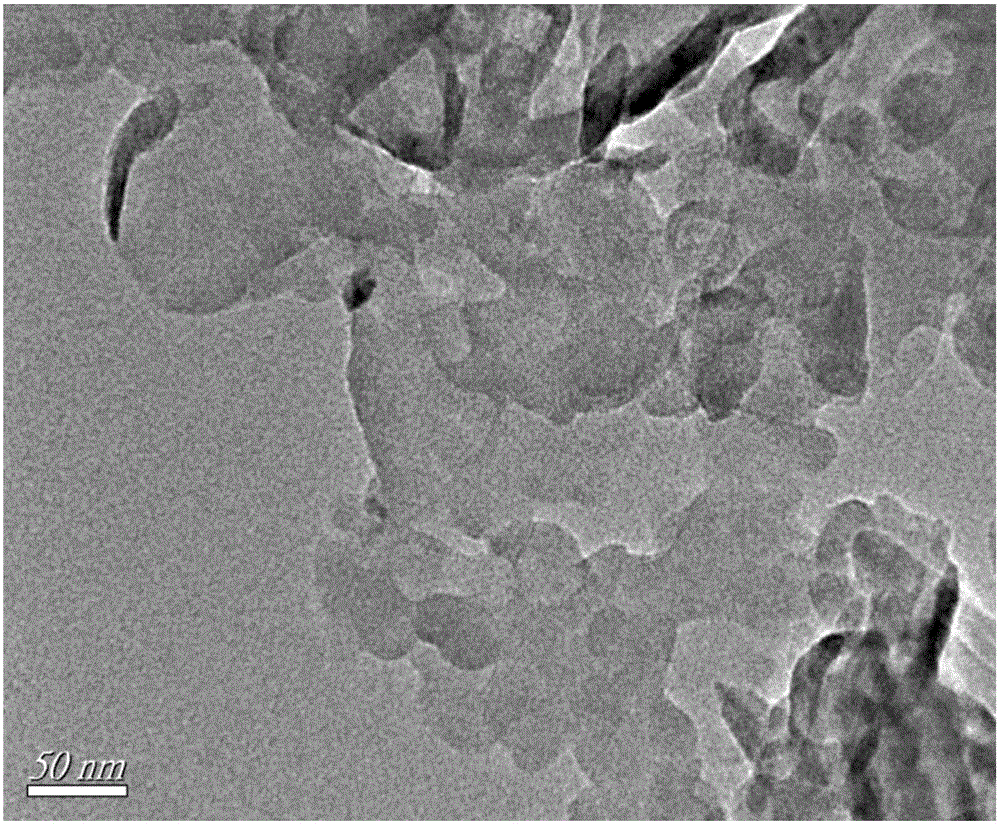

[0026] (2) Weigh again 0.1g g-C 3 N 4 Dissolve in 20mL microemulsion (volume ratio 1:1:1) mixed with polyethylene glycol octylphenyl ether, hexanol, and n-heptane, ultrasonically disperse for 10h, then add MoS 2 After the QDs (1%-10%) were ultrasonicated for 24 h, they were washed r...

Embodiment 2

[0028] The preparation method of molybdenum disulfide quantum dot modified graphitic carbon nitrogen, comprises the steps:

[0029] (1) Add 0.2g Na 2 MoO 4 and 0.45g Na 2 Dissolve S in 40 mL of deionized water, and add 2 mL of N 2 h 4 , after completely dissolving, continue to stir for 30min, then transfer the mixture to a 50mL stainless steel reaction kettle, place it in a vacuum drying oven at 280°C for 14h, and cool to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol, and finally dried at 80° C. for 10 h under vacuum to obtain a gray-black product powder, namely molybdenum disulfide quantum dots.

[0030] (2) Weigh again 0.1g g-C 3 N 4Dissolve in 20mL microemulsion mixed with polyethylene glycol octylphenyl ether, hexanediol and n-heptane, the volume ratio is 1:1:2, after ultrasonic dispersion for 10h, add MoS 2 After the QDs were 7% and continued to be sonicated for 24h, ...

Embodiment 3

[0032] The preparation method of molybdenum disulfide quantum dot modified graphitic carbon nitrogen, comprises the steps:

[0033] (1) Add 0.3g MoCl 5 and 0.5g K 2 Dissolve S in 40 mL of deionized water, and add 3 mL of N 2 h 4 , after completely dissolving, continue to stir for 30min, then transfer the mixture to a 50mL stainless steel reaction kettle, place it in a vacuum drying oven at 320°C for 18h, and cool to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol, and finally dried at 80° C. for 10 h under vacuum to obtain a gray-black product powder, namely molybdenum disulfide quantum dots.

[0034] Then weigh 0.1g g-C 3 N 4 Dissolve in 20mL microemulsion mixed with polyethylene glycol octylphenyl ether, hexanol and n-heptane, the volume ratio is 1:2:1, after ultrasonic dispersion for 10h, add MoS 2 After the QDs were 7% and continued to be sonicated for 24h, they were wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com