A method for removing heavy gas components from the reaction of oxidative dehydrogenation to butadiene plant

A technology for oxidative dehydrogenation and gas generation, which is applied in chemical instruments and methods, hydrocarbon purification/separation, organic chemistry, etc. It can solve the problem of increasing the replenishment of fresh absorbing oil, reducing the absorption effect of absorbing oil, and difficult to separate toluene, etc. problems, to achieve the effect of reducing heat, reducing usage, and reducing oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

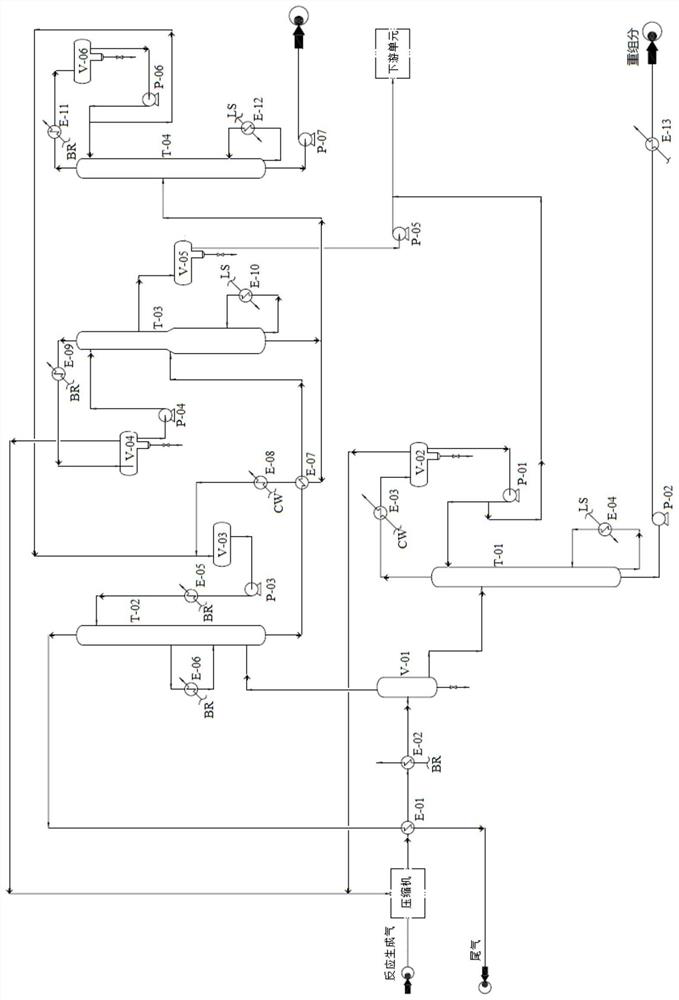

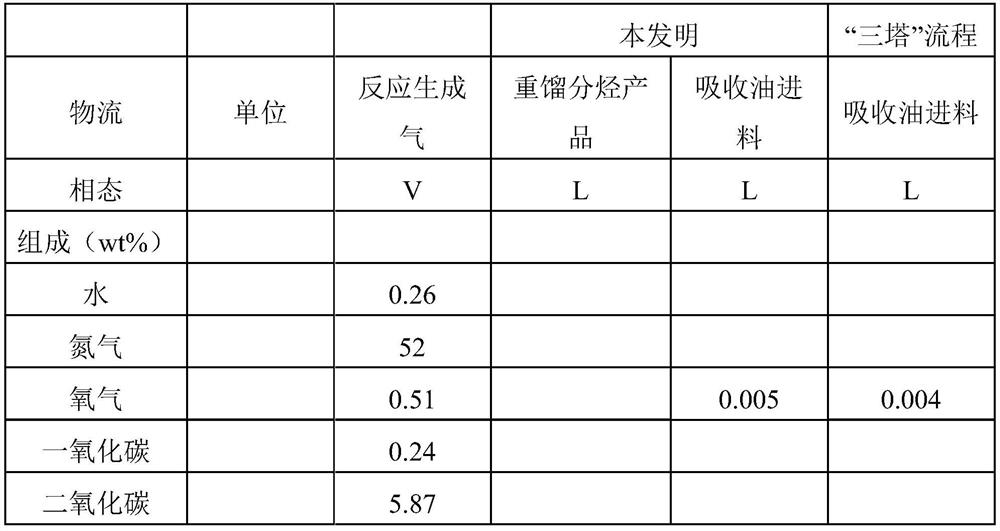

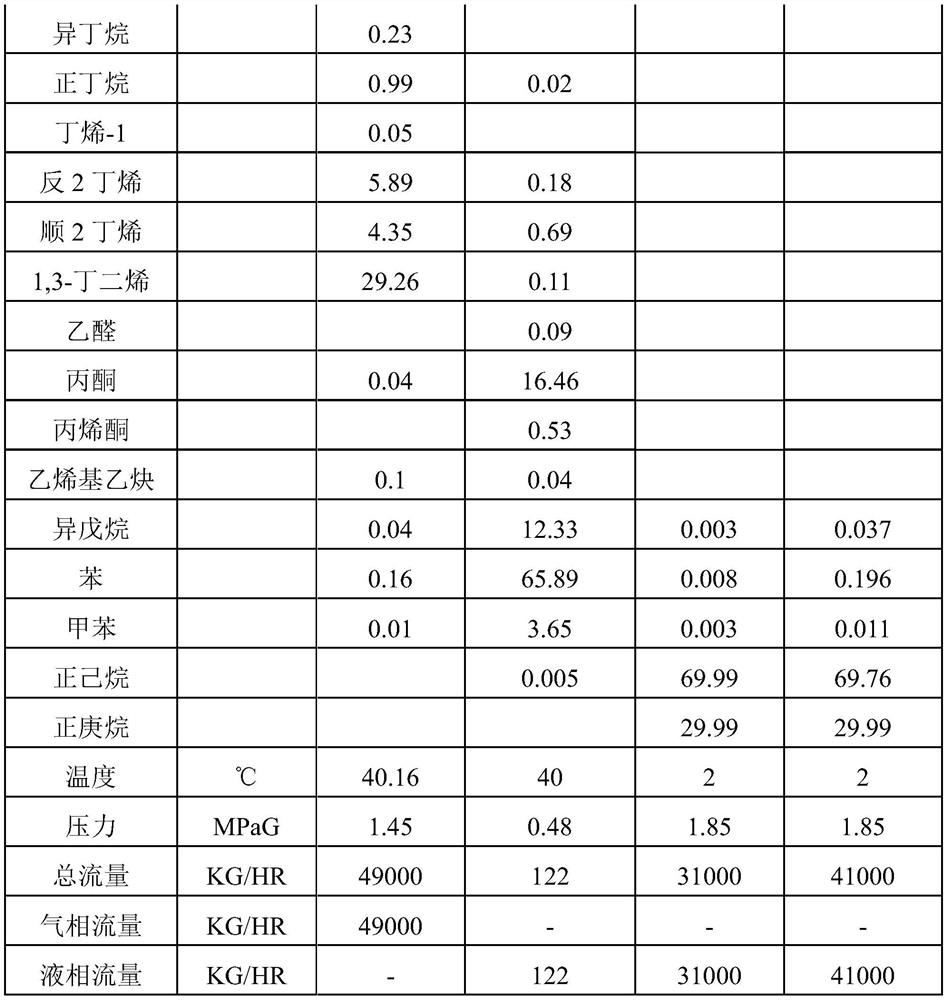

[0041] The reaction product gas enters the reaction product gas / tail gas heat exchanger E-01 and the reaction product gas condenser E-02 in turn, and is partially condensed after heat exchange, and the condensed material is separated into gas and liquid phases in the product gas separation tank V-01 to obtain Uncondensed gas and liquid crude butadiene:

[0042] 1) The uncondensed gas phase enters the oil absorption tower T-02 and contacts with the absorbed oil cooled by the absorbed oil feed cooler E-05 (~0°C) countercurrently, and C4 such as butadiene in the oil absorption tower T-02 The product is absorbed by the absorption oil composed of C6 and C7. At the position of the oil absorption tower T-02 near the tower kettle (that is, the position 10 to 15 trays away from the tower kettle), all the absorption oil is drawn out and passed through the intercooler E-06 of the oil absorption tower. After cooling, return to the lower tray to continue to contact with the gas phase to abso...

Embodiment 2

[0054] Compared with the reaction-generated gas separation process flow of embodiment 1, most of them are the same, except in this embodiment:

[0055] The operating pressure of the generated gas separation tank V-01 is 1.38MPaG, and the operating temperature is 2°C; the operating pressure at the top of the crude butadiene rectifying tower T-01 is 0.4MPaG, the tower top temperature is 35°C, and the tower bottom operating temperature is 130°C; The pressure at the top of the absorption tower T-02 is 1.35MPaG, the temperature at the top of the tower is 2°C, the temperature at the bottom of the tower is 18°C, and the temperature of the material returning to the oil absorption tower from the process side of the intercooler E-06 of the oil absorption tower is 8°C.

Embodiment 3

[0057] Compared with the reaction-generated gas separation process flow of embodiment 1, most of them are the same, except in this embodiment:

[0058] The operating pressure of the generated gas separation tank V-01 is 1.68MPaG, and the operating temperature is 0°C; the operating pressure at the top of the crude butadiene rectifying tower T-01 is 0.55MPaG, the tower top temperature is 55°C, and the operating temperature of the tower bottom is 110°C; The pressure at the top of the absorption tower T-02 is 1.65MPaG, the temperature at the top of the tower is 5°C, the temperature of the bottom of the tower is 28°C, and the temperature of the material returning to the oil absorption tower from the process side of the intercooler E-06 of the oil absorption tower is 12°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com