Near-infrared region II polymer fluorescent microsphere and preparation method thereof

A technology of polymer microspheres and fluorescent microspheres, applied in the field of near-infrared II region polymer fluorescent microspheres and their preparation, can solve the problems of reduced analytical sensitivity, poor fluorescence penetration performance, high requirements for color filters, etc. Improve detection sensitivity, small background interference, and strong penetrating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

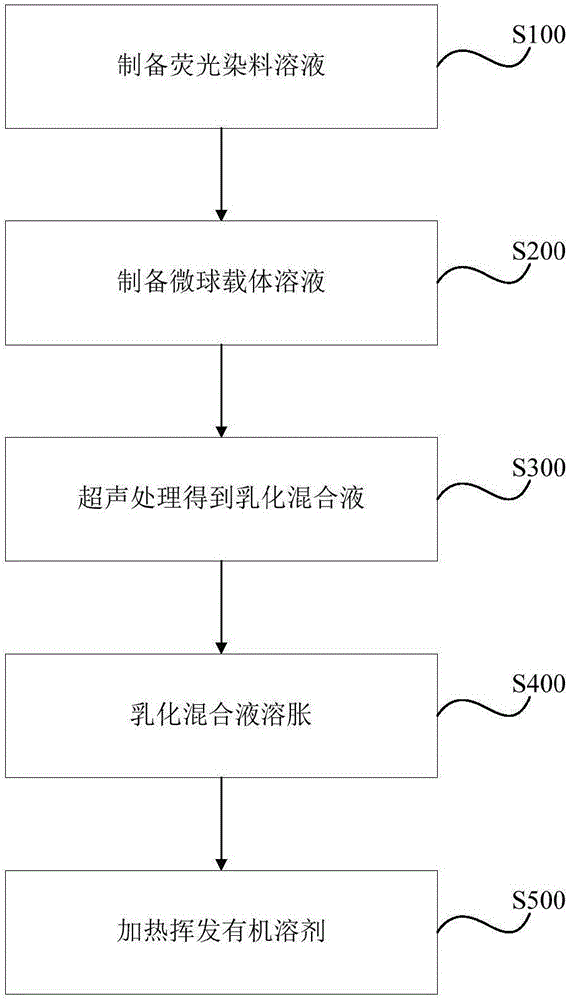

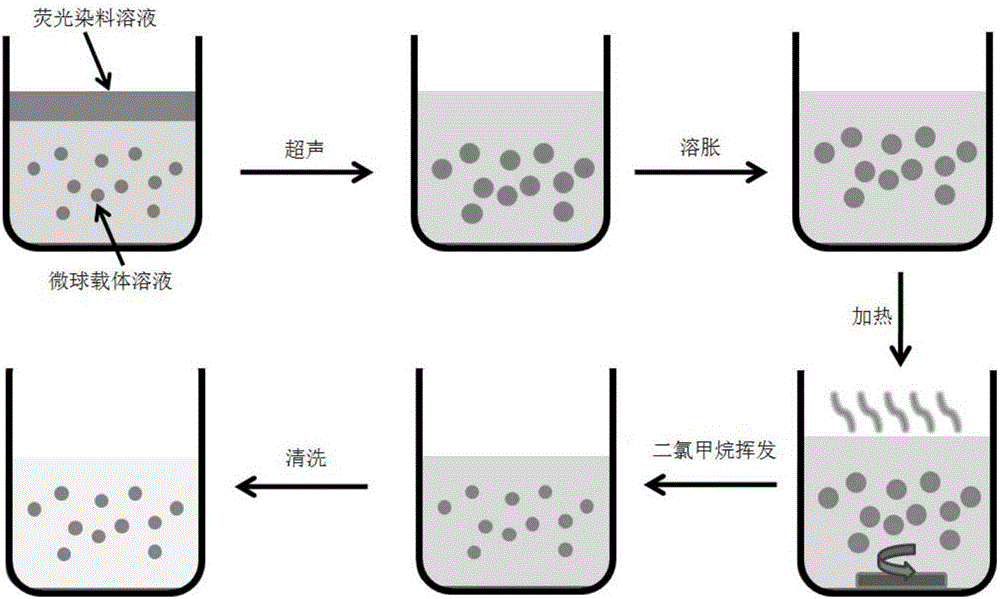

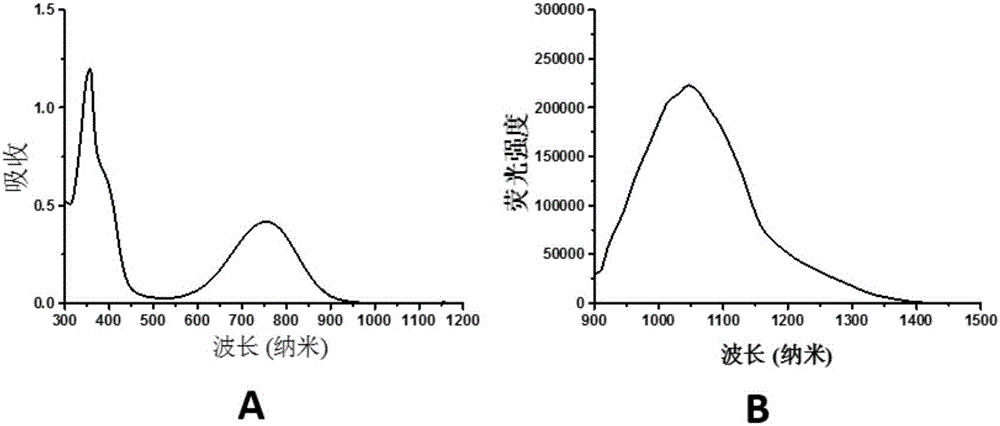

[0032]According to one aspect of the present invention, the present invention proposes a method for preparing polymer fluorescent microspheres in the near-infrared II region, including: (1) using a water-immiscible organic solvent to dissolve the fluorescent dye, so as to obtain the fluorescent dye solution, the fluorescent dye has a structure shown in formula I; (2) polymer microspheres are dispersed in an aqueous solution of sodium dodecylsulfonate to obtain a microsphere carrier solution; (3) the fluorescent dye solution and the microsphere carrier solution Mixing and ultrasonic treatment to obtain an emulsified mixed solution; (4) swelling the emulsified mixed solution so that the fluorescent dye solution is immersed in the nanopores produced during the swelling process of the polymer microspheres; and (5) performing step (4) The mixture obtained in the process is heated, and with the volatilization of the organic solvent, the fluorescent dye crystallizes out and is wrapped...

Embodiment 1

[0064] (1) Synthesis of carboxylated polystyrene microspheres

[0065] Add 190ml of water into a 500ml round-bottomed flask, and stir at 350rpm in a 70°C water bath for half an hour. Then add 16mg SDS as emulsifier, 0.05g sodium bicarbonate as buffer reagent. Stirring was continued for 10 minutes and 8 mL of styrene and 0.8 mL of acrylic acid were added to the flask. After one hour, 0.2 g of potassium persulfate was added, and the polymerization was carried out under nitrogen protection for 18 hours. After the reaction, wash with 2:1 (v / v) ethanol and aqueous solution and centrifuge three times to obtain carboxylated polystyrene microspheres. Image 6 (A) shown. Carboxylated polystyrene microspheres are dispersed in the SDS aqueous solution that concentration is 0.25% (w / v) then, configure the carboxylated polystyrene microsphere dispersion liquid of 30mg / ml, as Figure 5 As shown in (A), and stored in a 4-degree refrigerator.

[0066] (2) Synthesis of carboxypolystyrene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com