Preparation method of graphene-carbon nanotube composite material loaded with nano-copper particle lubricating material

A technology of carbon nanotubes and composite materials, applied in the direction of lubricating compositions, petroleum industry, additives, etc., can solve the problems of expensive instruments, complicated experimental steps, high cost of composite materials and difficulty in popularization and application, and achieve the effect of improving friction and wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

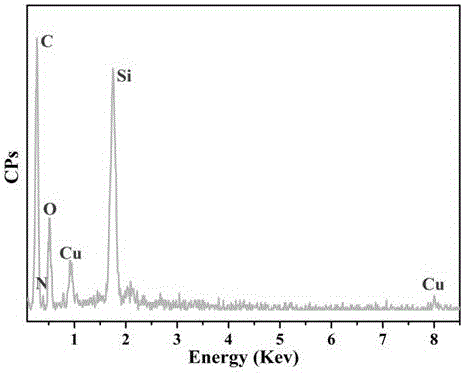

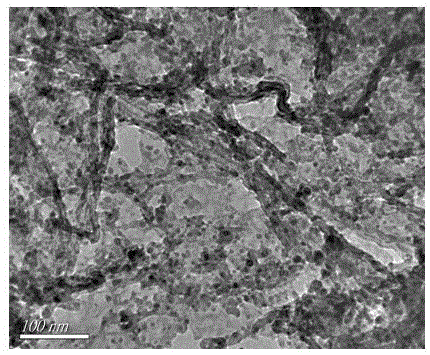

[0025] Step 1: Disperse 0.025g GO and 0.05gCNTs into 200 mL Tris-HCl buffer (pH=8.5) under the action of ultrasound. Then add 0.4 g of dopamine hydrochloride and react for 12 hours under strong magnetic stirring. Repeated centrifugal washing with distilled water and ethanol several times to remove impurities such as free PDA. Finally, the PDA / GO-CNTs sample powder can be obtained by drying in a freeze drying oven.

[0026] Step 2: Disperse 0.02 g of PDA / GO-CNTs evenly in 50 mL of ethanol solution under the action of ultrasound, then add 0.15 g of copper acetate and stir to dissolve it. Take another beaker and dissolve 0.12g of sodium hypophosphite into 40mL of ethanol solution. The above two liquids were added into the flask, and reacted at 80° C. for 20 minutes under the action of stirring in a constant temperature magnetic stirring water bath. The flask was taken out, cooled to room temperature, washed by centrifugation, and dried in vacuum to obtain Cu / PDA / GO-CNTs sample...

Embodiment 2

[0032] Step 1: Disperse 0.01g GO and 0.05gCNTs into 200 mL Tris-HCl buffer (pH=8.5) under the action of ultrasound. Then add 0.4 g of dopamine hydrochloride and react for 12 hours under strong magnetic stirring. Repeated centrifugal washing with distilled water and ethanol several times to remove free PDA and other magazines. Finally, the PDA / GO-CNTs sample powder can be obtained by drying in a freeze drying oven.

[0033] Step 2: Disperse 0.02 g of PDA / GO-CNTs uniformly in 50 mL of ethanol solution under the action of ultrasound, then add 0.15 g of copper sulfate, and stir to dissolve it. Take another beaker and dissolve 0.1g of sodium hypophosphite into 40 mL of ethanol solution. The above two liquids were added into the flask, and reacted at 80° C. for 20 minutes under the action of stirring in a constant temperature magnetic stirring water bath. The flask was taken out, cooled to room temperature, washed by centrifugation, and dried in vacuum to obtain Cu / PDA / GO-CNTs sa...

Embodiment 3

[0035] Step 1: Disperse 0.01g GO and 0.05gCNTs into 200 mL Tris-HCl buffer (pH=8.5) under the action of ultrasound. Then add 0.4 g of dopamine hydrochloride, and react for 12 hours under strong magnetic stirring. Repeated centrifugal washing with distilled water and ethanol several times to remove free PDA and other magazines. Finally, the PDA / GO-CNTs sample powder can be obtained by drying in a freeze drying oven.

[0036]Step 2: Disperse 0.02 g of PDA / GO-CNTs uniformly in 50 mL of ethanol solution under the action of ultrasound, then add 0.2 g of copper nitrate and stir to dissolve it. Take another beaker and dissolve 0.1 g of sodium borohydride into 40 mL of ethanol solution. The above two liquids were added into the flask, and reacted at 80° C. for 20 minutes under the action of stirring in a constant temperature magnetic stirring water bath. The flask was taken out, cooled to room temperature, washed by centrifugation, and dried in vacuum to obtain Cu / PDA / GO-CNTs sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com