Preparation of amidoxime modified magnetic nano biological adsorbent and method for adsorbing low-concentration uranium by utilizing amidoxime modified magnetic nano biological adsorbent

A biological adsorbent and magnetic nanotechnology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problems of low adsorption efficiency, low recycling rate, high production cost, etc., and achieve high adsorption rate High, stable adsorption effect, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] The preparation of the adsorbent provided by the invention and the specific steps of adsorbing low-concentration uranium are:

[0039] (1) Weigh 6.8g FeCl 3 ·6H 2 0 In the Erlenmeyer flask, add 400ml of ethylene glycol solution, after stirring for 15min, an orange-yellow clear liquid is obtained, add 18g of anhydrous sodium acetate and 5g of trisodium citrate, continue stirring for 1h, and pour the solution into a high-temperature reaction kettle, React at 200°C for 10h, cool to room temperature naturally, wash with distilled water and ethanol several times, and dry in vacuum at 50°C for 24h to obtain nano-Fe 3 o 4 ;

[0040] (2) Take 1g nanometer Fe 3 o 4 In the Erlenmeyer flask, add 50ml of toluene solution, after ultrasonication for 20min, add 1.34ml of (2-cyanoethyl)triethoxysilane, and react for 48h at 100°C under the condition of nitrogen gas, wash with ethanol several times, at 50 After vacuum drying at ℃ for 24 hours, the nano-Fe modified with cyano group ...

Embodiment 1

[0044] IV embodiment 1 The preparation of the adsorbent provided by the patent of the present invention:

[0045] (1) Preparation of Aspergillus niger powder

[0046] Gently scrape the cultivated fungal solid slant with an inoculation loop to prepare 500 mL of bacterial suspension with an OD value of 0.1, inoculate it into the PDA liquid medium at an inoculum amount of 2 / 1000, and inoculate in a shaker (30°C, 150rpm ) for extended cultivation for 60 hours. After a large amount of mycelia grew on the surface of the culture medium, the mycelium was taken out, washed with ultrapure water, put into an oven at 30°C for 24 hours, and ground through a 100-mesh standard inspection sieve with a pulverizer to collect 100 Aspergillus niger powder of the following order;

[0047] (2) Nano-Fe modified by amidoxime 3 o 4 preparation of

[0048] Weigh 6.8g FeCl 3 ·6H 2 O in a conical flask, add 400ml ethylene glycol solution, stir for 15min to obtain an orange-yellow clear liquid, add ...

Embodiment 2

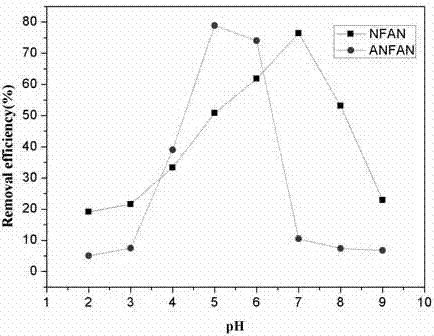

[0051] Example 2, respectively pipette 20 mL of uranium solution with an initial concentration of 10 mg / L in a 50 mL Erlenmeyer flask, and sequentially adjust the pH value of the solution to 2, 3, 4, 5, 6, 7, 8, 9 in triplicate, Add 0.010g magnetic nano-Fe respectively 3 o 4 - Aspergillus niger biosorbent / 0.010g The adsorbent provided by the patent of the present invention, oscillating and adsorbing in a constant temperature culture shaker with a rotation speed of 150rpm at 25°C, counting from the time when the adsorbent is added to the solution, oscillating and adsorbing for 300min, and measuring the residual uranium in it concentration. When the pH is 2-9, the magnetic nano-Fe 3 o4 -The adsorption rate of Aspergillus niger biosorbent is 19.17%, 21.61%, 33.33%, 50.85%, 61.83%, 76.36%, 53.18%, 22.92%; the adsorption rate of ANFAN is 5.04%, 7.5%, 39.04%, 78.89%, 10.5%, 7.39%, 6.76%. It can be seen that the magnetic nano-Fe 3 o 4 - The Aspergillus niger biosorbent reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com