Method directly using acid and alkaline activation of red mud to prepare iron type denitrifying catalyst

A denitrification catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve a wide range of industrial application prospects, meet industrial needs, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

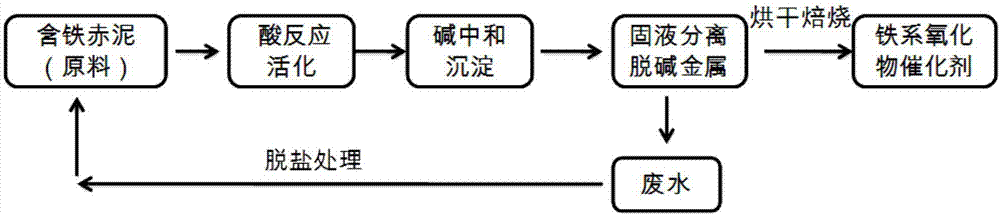

Method used

Image

Examples

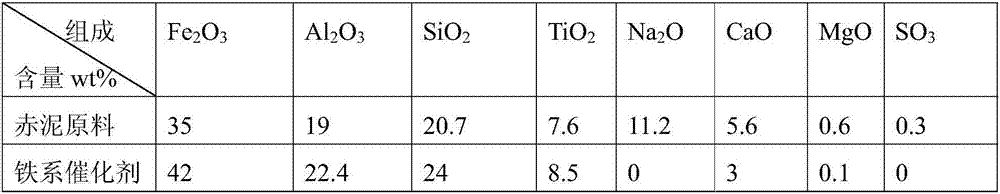

Embodiment 1

[0049] This embodiment provides a method for preparing an iron-based denitration catalyst from red mud, and the specific method is as follows:

[0050] (1) To 1kg of red mud (Fe in red mud 2 o 3 After adding 3kg of waste hydrochloric acid (concentration: 20%) to the mass fraction of 35%, it was reacted at 80° C. for 10 h to obtain a uniform first slurry with a solid content of 25% and a pH of 2;

[0051] (2) adding ammonia water (the mass fraction of ammonia in the ammonia water is 10%) successively to the first slurry, the pH value of the solution is about 9, the silica-alumina sol precipitates again, the viscosity of the system becomes smaller, and the second slurry is obtained;

[0052] (3) After the second slurry is subjected to solid-liquid separation and washing, it is dried at 100° C., and then calcined at 600° C. for 5 hours to obtain a solid substance, which is an iron-titanium-silicon-aluminum oxide denitration catalyst. The water phase obtained by solid-liquid sep...

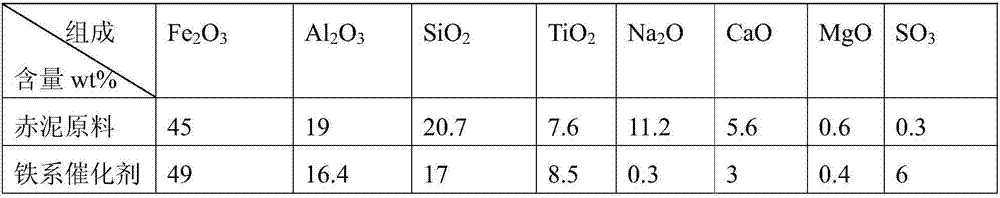

Embodiment 2

[0059] This embodiment provides a method for preparing an iron-based denitration catalyst from red mud, and the specific method is as follows:

[0060] (1) To 1kg of red mud (Fe in red mud 2 o 3 After adding 10 kg of waste sulfuric acid (concentration 40%) into the mass fraction of 45%, it was reacted at 120° C. for 10 h to obtain a uniform first slurry, and the pH of the first slurry was 0.5;

[0061] (2) slowly successively ammonium carbonate powder in the first slurry, control solution terminal pH value is about 6, obtains the second slurry;

[0062] (3) After the second slurry is subjected to solid-liquid separation and washing, it is dried at 100° C., and then calcined at 500° C. for 10 hours to obtain a solid substance, that is, an iron-titanium-silicon-aluminum oxide denitration catalyst.

[0063] The specific surface area of the iron-titanium-silicon-aluminum oxide denitration catalyst obtained in this example is 190m 2 / g, the strength is 4.5Mpa, and the composit...

Embodiment 3

[0068] This embodiment provides a method for preparing an iron-based denitration catalyst from red mud, and the specific method is as follows:

[0069] (1) To 1kg of red mud (Fe in red mud 2 o 3 After adding 1kg of waste phosphoric acid (concentration: 10%) to 10% by mass fraction), it was reacted at 70°C for 20h to obtain a uniform first slurry, and the pH of the first slurry was 0;

[0070] (2) slowly successive ammonium carbonate powder in the first slurry, control solution terminal pH value is about 5, obtains the second slurry;

[0071] (3) After the second slurry is subjected to solid-liquid separation and washing by plate and frame filter press, it is dried at 100°C, and then roasted at 400°C for 20 hours to obtain a solid substance, which is an iron-titanium-silicon-aluminum oxide denitrification catalyst .

[0072] The specific surface area of the iron-titanium-silicon-aluminum oxide denitration catalyst obtained in this example is 150m 2 / g, the strength is 4.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com