Metal-plastic double-layer combined part and preparation method thereof

A joint and plastic technology, applied in the direction of coating, etc., can solve the problems such as the thermal conductivity of joints, the thermal conductivity of metal and plastic joints, and poor thermal conductivity, etc., to achieve good thermal conductivity and good thermal conductivity. Interface strength, the effect of improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing the metal-plastic double-layer combination described in the above technical solution, comprising the following steps:

[0031] Mix carbon fiber with boron nitride and PA66 to obtain PA66 composite material;

[0032] Surface-treating the aluminum alloy metal plate to obtain a metal plate with micropores on the surface;

[0033] performing plasma activation on the metal plate with micropores on the surface to obtain an activated metal plate;

[0034] Injection molding the PA66 composite material on the surface of the activated metal plate to obtain a molded sample;

[0035] The molded sample is subjected to heat preservation treatment to obtain a metal-plastic double-layer combination.

[0036] The invention mixes carbon fiber, boron nitride and PA66 to obtain PA66 composite material. In the present invention, the humidity of the PA66 composite material is preferably less than 0.2%. In the present invention, t...

Embodiment 1

[0048] 45 parts of PA666, 20 parts of carbon fiber (diameter 5 μm, length 0.5 mm), 35 parts of hexagonal boron nitride BN (diameter 5 μm, thickness 100 nm), after mixing evenly, add to the feeding port of the twin-screw extruder, twin-screw extruder The temperature of the 5 extrusion temperature zones of the extruder is 270° C., and the rotation speed of the extrusion screw is 80 rpm for extrusion granulation.

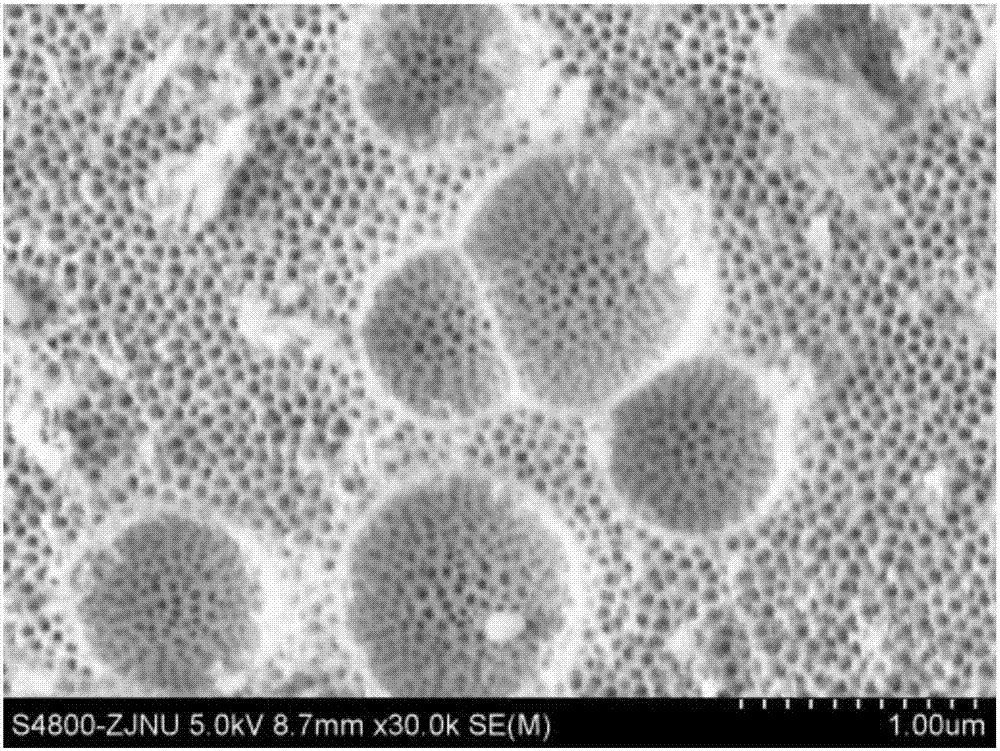

[0049] Select an aluminum alloy 6063 plate of 2mm×Ф12.7mm, wash away the iron filings stains on the surface of the machined aluminum sheet with deionized water, place the aluminum sheet in a 5% NaOH solution, make the solution immerse the aluminum sheet sample, and ultrasonically Take out after shaking for 5 minutes. Then put the shaken aluminum sheet into acetone, soak for 30s, remove the remaining NaOH solution on the surface, and then perform anodic oxidation microporous treatment on the aluminum alloy plate to obtain a metal plate with a micropore diameter of 40nm....

Embodiment 2

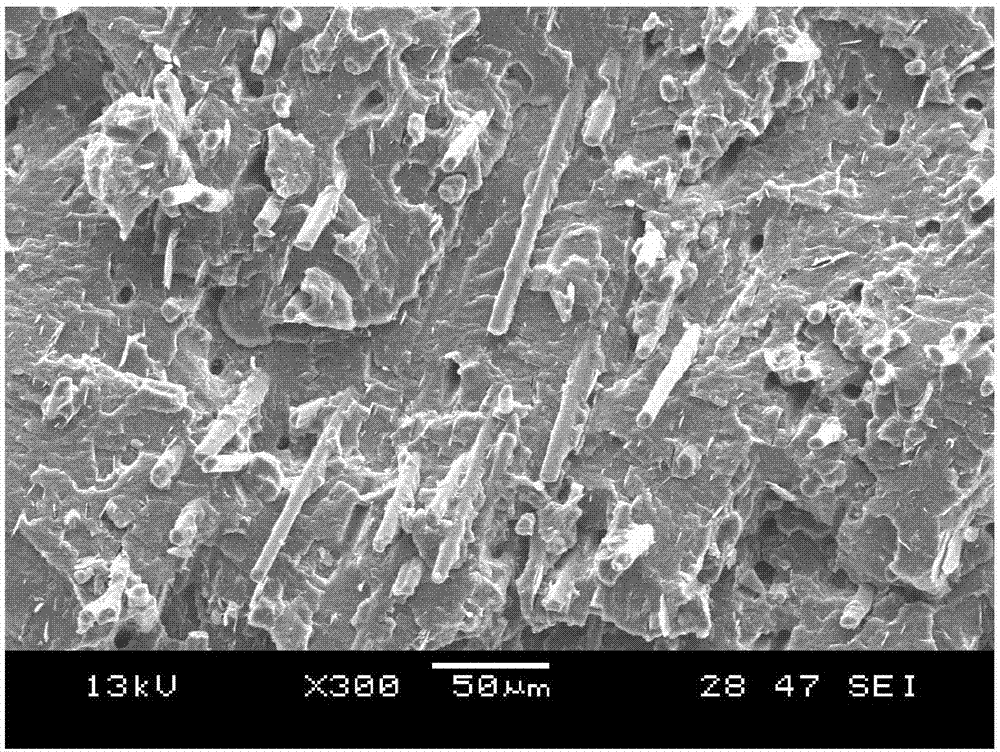

[0057] 45 parts of PA666, 25 parts of carbon fiber (diameter 20μm, length 6mm), 30 parts of hexagonal boron nitride BN (diameter 35μm, thickness 300nm), after mixing evenly, add to the feeding port of the twin-screw extruder, twin-screw extrusion The temperature of the 8 extrusion temperature zones of the machine is 260° C., the rotation speed of the extrusion screw is 150 rpm, and extrusion granulation is performed.

[0058] Select an aluminum alloy 6063 plate of 2mm×Ф12.7mm, wash away the iron filings stains on the surface of the machined aluminum sheet with deionized water, place the aluminum sheet in a 5% NaOH solution, make the solution immerse the aluminum sheet sample, and ultrasonically Take out after shaking for 5 minutes. Then put the shaken aluminum sheet into acetone, soak for 30s, remove the remaining NaOH solution on the surface, and then perform micro-porous treatment on the aluminum alloy plate to obtain a metal plate with a micro-pore diameter of 20 μm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com