An intelligent water-seeking water shutoff agent for high-temperature horizontal wells

A technology for horizontal wells and water plugging agents, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of small rotational freedom of chain links, high density of benzene rings, easy breakage, etc., and achieves application process safety, The effect of high selectivity and high transaction intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

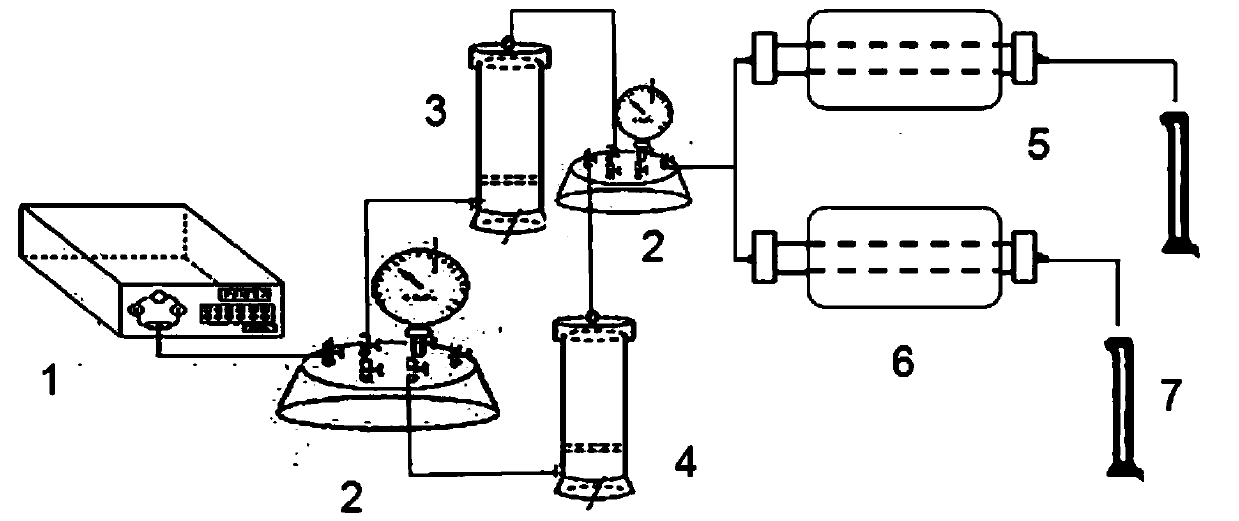

Image

Examples

Embodiment 1

[0055] This embodiment provides a kind of resole phenolic prepolymer, and it is prepared through the following steps:

[0056] Add 15g of sodium hydroxide and 60g of phenol into a 500mL three-neck flask equipped with a thermometer, a reflux condenser, and magnetic stirring, and add 140g of formaldehyde solution with a mass fraction of 33%-37% while stirring continuously;

[0057] React at 45°C-95°C for 4 hours to obtain a resole phenolic prepolymer solution;

[0058] Cool the resole phenolic prepolymer solution of this embodiment and store it in a refrigerator. FTIR, V / cm -1 : 3362, 1478 (characteristic peak), 1054 (V CH2-O-CH2 ), 751 (V C-CH2 o), 879 (V C-CH2 right).

Embodiment 2

[0060] This embodiment provides a kind of melamine formaldehyde prepolymer, and it is prepared through the following steps:

[0061] Add 60g of formaldehyde into a 250mL three-neck flask equipped with a thermometer, reflux condenser, and magnetic stirring, adjust the pH value to weak alkaline with a dilute sodium hydroxide solution, add 26g of melamine, heat in a water bath while stirring, and heat up after the melamine is completely dissolved. to 50°C-80°C, adjust the pH value with dilute hydrochloric acid and washing lye, and react for 2-4 hours to obtain a melamine formaldehyde prepolymer solution.

[0062] Store the above-mentioned melamine-formaldehyde prepolymer solution of this embodiment at room temperature. FTIR, V / cm -1 : 1560,1450 (V C=N ), 1050 (V C-O-C methylol etherification), 1010 (hydroxymethyl characteristic peak).

Embodiment 3

[0064] This embodiment provides a pyrolysis type curing agent, which is prepared through the following steps:

[0065] Add 25g of neopentyl glycol and 70ml of chloroform into a 250mL four-neck flask equipped with a thermometer, reflux condenser, magnetic stirring, and tail gas absorption device, and slowly add 30mL of phosphorus oxychloride dropwise at room temperature. to 65°C, react for 5h, until no HCl gas is released, distill off the chloroform and excess phosphorus oxychloride to obtain a white solid, the intermediate 5,5-dimethyl-1,3-dioxaphosphorinine Alkylphosphoryl chloride, yield 83.5%.

[0066] Add chloroform and intermediates to the three-necked flask, add water dropwise at room temperature, and control the reaction temperature at 50°C until the reaction temperature does not change with the addition of water, indicating that the hydrolysis reaction is fully completed, separate the chloroform, and neutralize the aqueous phase with sodium hydroxide. Distillation und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com