Gas-solid mixed heating powdered oil shale destructive distillation apparatus

A solid mixing and heating technology, applied in the direction of direct heating dry distillation, special form dry distillation, petroleum industry, etc., can solve problems such as control and unification of unfavorable particle residence time, insufficient economic benefits, large-scale commercial production, and disordered gas flow state. , to achieve the effect of stable and uniform gas flow state, improving comprehensive utilization rate, and uniform drop distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

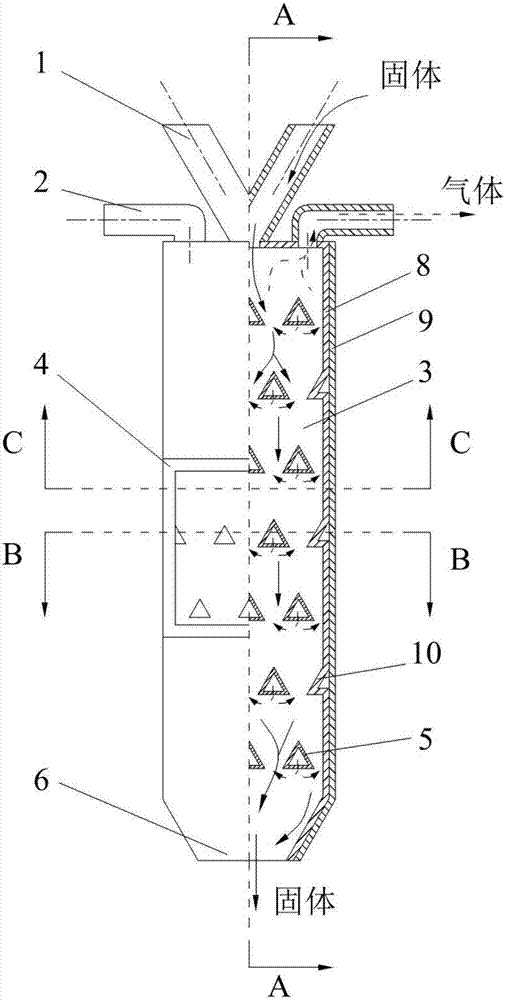

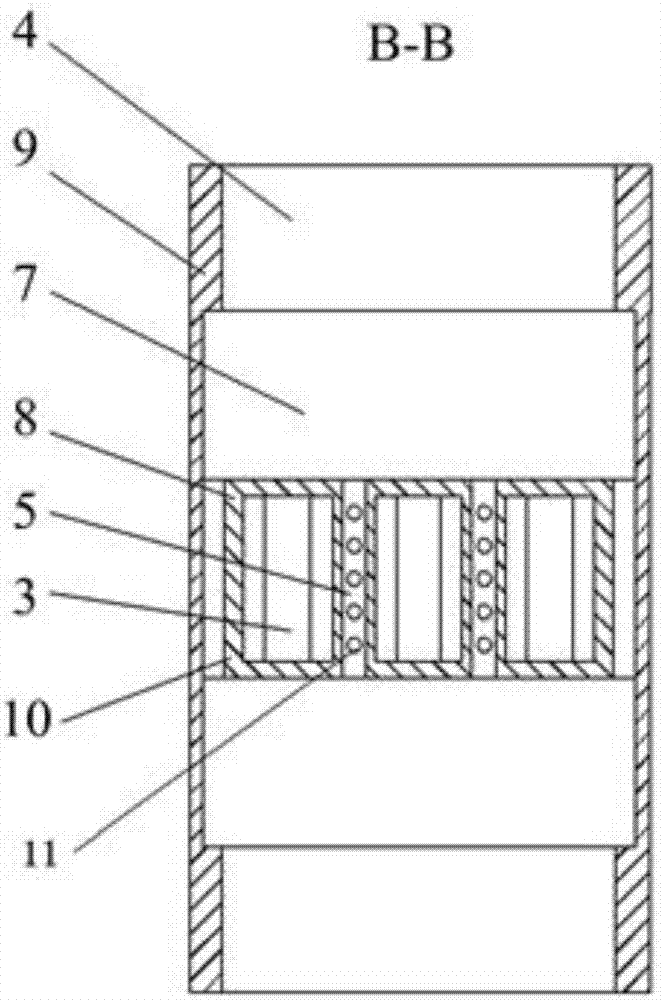

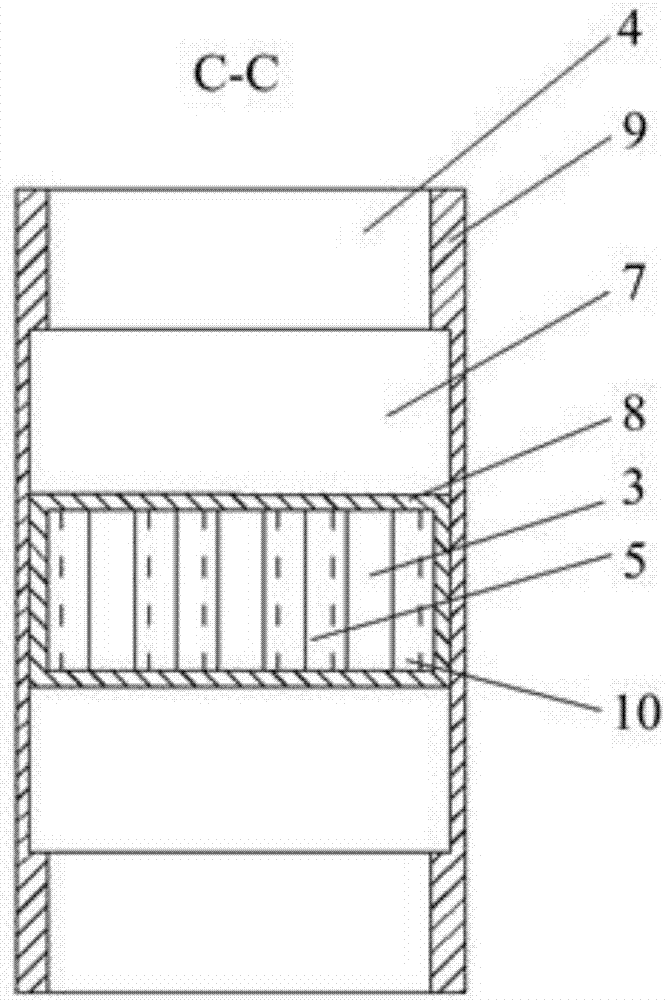

[0028] refer to Figure 1-Figure 4 , a gas-solid mixed heating powdery oil shale retort device of the present invention, it comprises an air distribution chamber shell 9, a reaction chamber shell 8, and a reaction chamber shell 8 is placed at the center of the air distribution chamber shell 9 , a reaction chamber 3 is provided in the reaction chamber shell 8, and the feed pipe 1 and the air outlet pipe 2 arranged on the top of the reaction chamber 3 are all connected with the reaction chamber 3, and several folds are arranged on the inner wall of the reaction chamber 3 The flow plate 10, the lower part of the reaction chamber 3 is provided with a discharge port 6, and the reaction chamber 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com