CO2 energy power generation system with clean afterburning and multielement heat exchange of heat engine exhaust smoke

A technology for energy generation, CO2, used in machines/engines, engine components, combustion using catalytic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

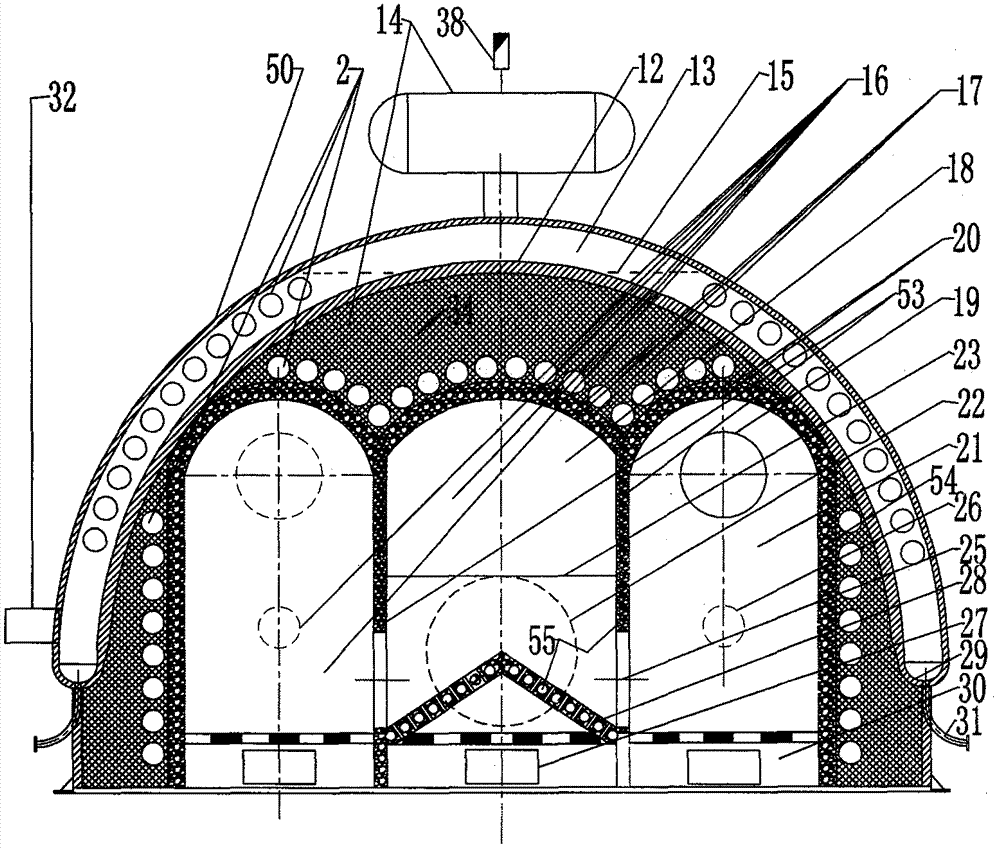

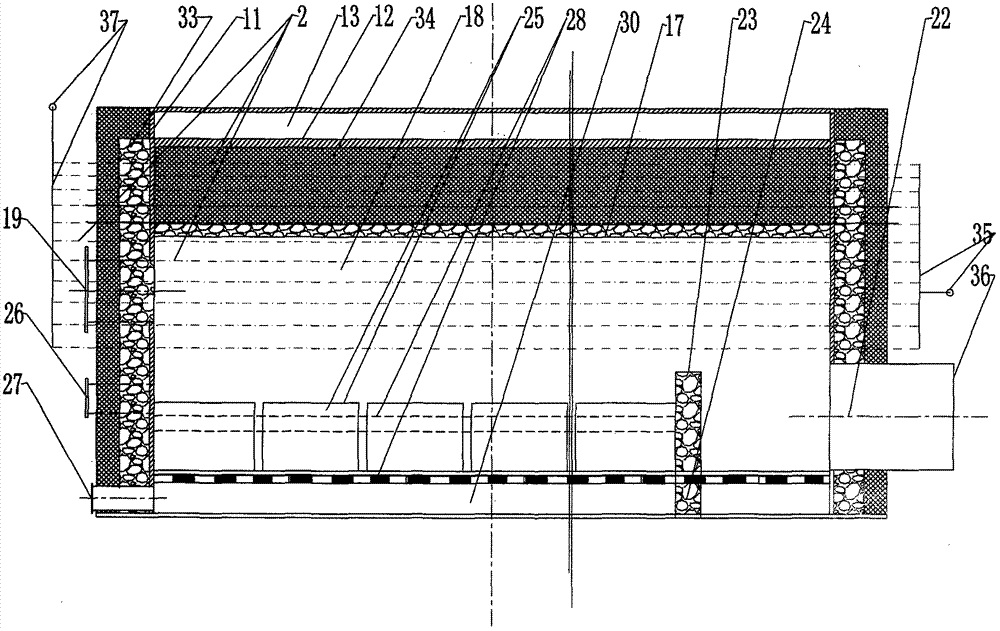

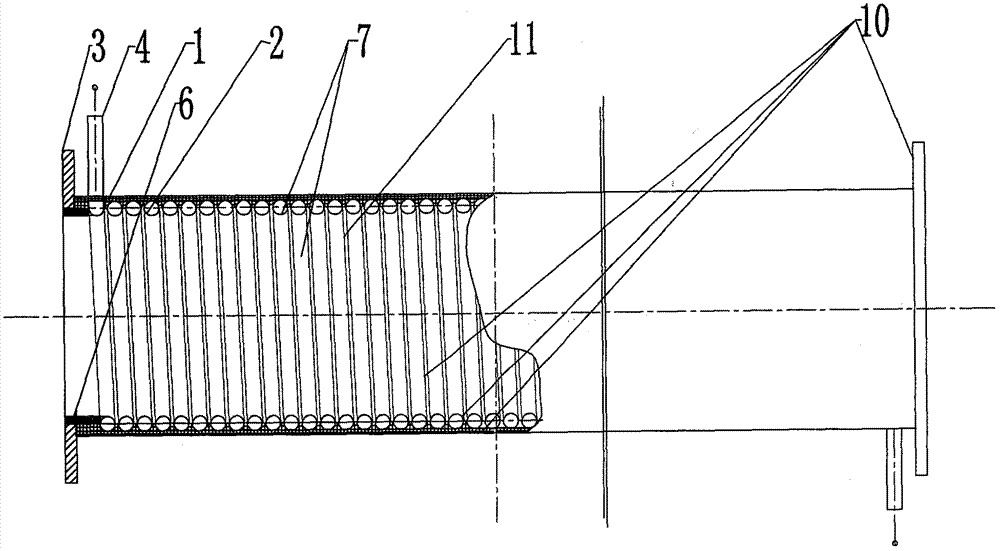

[0017] exist figure 1 In the semicircular furnace body 50 of the post-combustion hearth furnace 16, the inner tank half cylinder 12 and the semicircular pressure-bearing cylinder of the oil area 13 are built symmetrically with the two refractory middle walls 53 and the outer sides by the vacuum furnace hearth arch 17. The three arches of the gasification chamber arch 20 above the furnace wall 54 (the upper three arches and the outer sides of the furnace wall 54 are arranged along the arch wall in parallel closed inlet and outlet water flows and are filled by aluminum silicate felt filler 34 to the semicircular furnace body. 50 cooling in the thermal insulation layer), the vacuum furnace 18 in the corresponding space under the arch and the gasification chamber 21 symmetrical on both sides are the structural centers. The lower part of the cooling refractory middle wall 53 on both sides of the vacuum furnace 18 is left and right symmetrically opened through the burner 25 and onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com