Strontium-doped nitrogen-containing porous carbon material and preparation method and application thereof

A porous carbon material and strontium doping technology, applied in the field of carbon porous materials, can solve the problems of high cost, low specific capacitance, cumbersome electrode material preparation process, etc., and achieve high specific surface area, simple preparation process, and favorable electron transport. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of strontium-doped nitrogen-containing porous carbon material is as follows:

[0037] Step 1) Preparation of strontium-containing precursors, 4 g of glucose, 2 g of semicarbazide, 31.2 mg of strontium nitrate, and 32.1 mg of sodium borohydride were sequentially added to deionized water, stirred and dissolved, and then put into a reaction kettle at 180 °C reaction, after which the product is filtered, washed, and dried to obtain a strontium-containing precursor;

[0038] Step 2) Activation of the strontium-containing precursor, mixing the strontium-containing precursor and KOH at a mass ratio of 1.0:2.0, soaking in deionized water and stirring, drying in a blast drying oven, and then calcining at 700 °C for 2 h under nitrogen protection , after cooling down, take out the roasted sample and grind it to obtain an activated strontium-containing precursor material;

[0039] Step 3) Post-treatment of the strontium-containing precursor, washing the abov...

Embodiment 2

[0045] In order to compare the effect of adding strontium content on the synthesis of carbon materials, a strontium-doped porous carbon material with twice the amount of strontium nitrate was prepared. The specific steps of the preparation method are the same as the preparation method of Example 1, except It is: the mass of strontium nitrate in the step 1) is 62.4 mg.

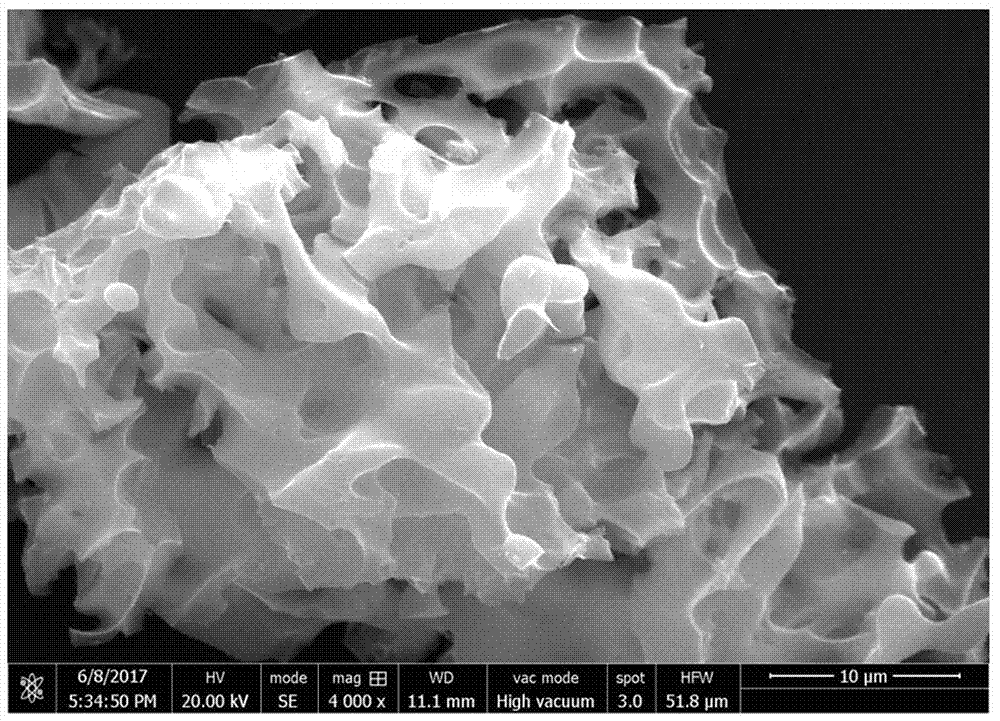

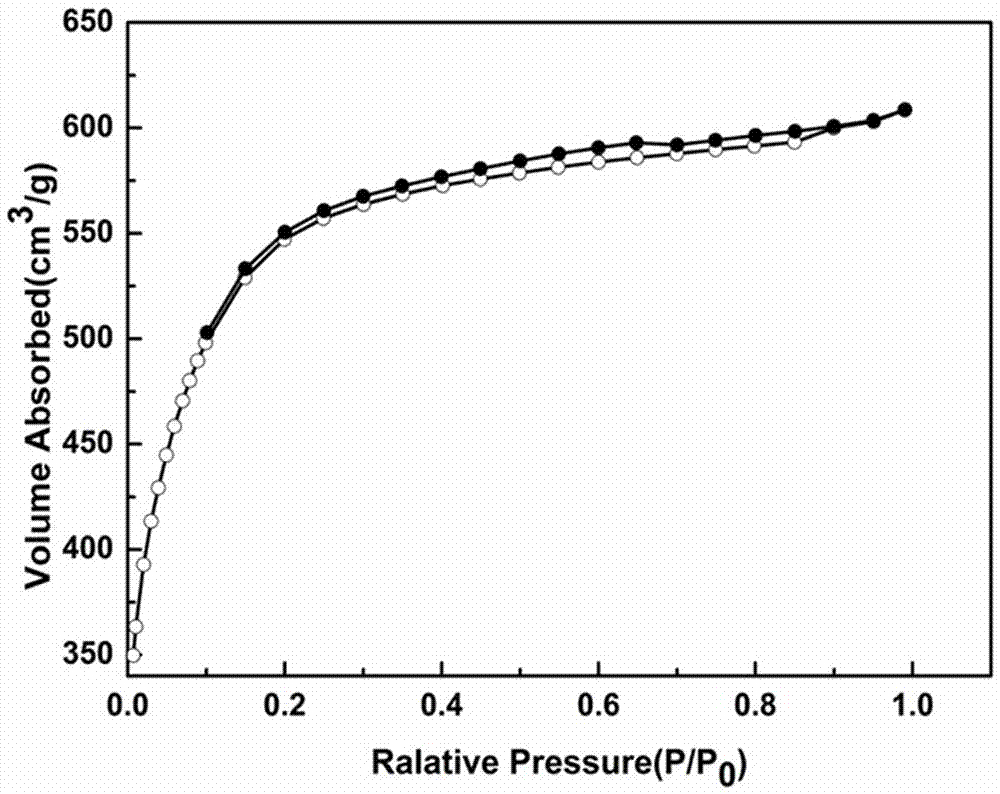

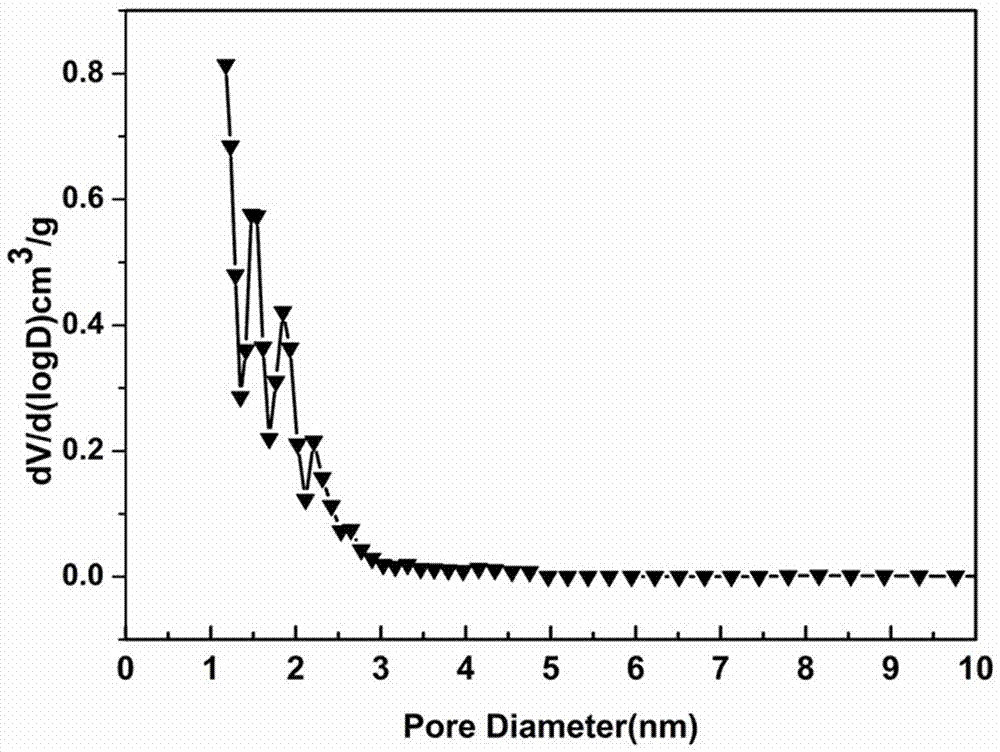

[0046] Isotherm adsorption curve and pore size distribution in embodiment 2, such as Image 6 and 7 As shown, the results show that the specific surface area is 2485 m 2 g -1 , with a total pore volume of 0.841 cm 3 g -1 .

[0047] The specific capacity test test result under the constant current charge and discharge of different rate in embodiment 2 is as follows Figure 8 As shown, when the current density is 0.5 A g -1 , the specific capacitance value reaches 325 F g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com