A method for testing the sintering resistance of coated sand for steel castings

A detection method and technology of coated sand, which is applied in casting moulds, casting molding equipment, chemical analysis by combustion, etc., can solve the problems of casting scrapping, etc., and achieve the effects of good scouring force, low expansion performance, and high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of coated sand for steel castings, comprising the following raw materials: quartz silica sand, iron ore sand, zeolite powder, graphite powder, phenolic resin, silane coupling agent, urotropine solution and calcium stearate, described quartz silica sand and Iron ore is raw sand;

[0046] Wherein, the quartz silica sand is 1000 parts by weight, the iron ore is 5wt% of the total amount of the quartz silica sand, the phenolic resin is 3wt% of the original sand, and the urotropine solution is the 10wt% of the phenolic resin, and the graphite powder, zeolite powder and calcium stearate are 10wt% of the former sand.

[0047] The particle size of described quartz silica sand and iron ore powder is 20-300 order, and the Fe in described iron ore 3 o 4 Content ≥ 85%, 90 wt% of the particle size of the graphite powder is less than 500 mesh, the ammonia absorption of the zeolite powder is greater than 100 mmol / 100g, the particle size of the zeolite powder is 200 mesh, in th...

Embodiment 2

[0065] A kind of coated sand for steel castings, comprising the following raw materials: quartz silica sand, iron ore sand, zeolite powder, graphite powder, phenolic resin, silane coupling agent, urotropine solution and calcium stearate, described quartz silica sand and Iron ore is raw sand;

[0066] Wherein, the quartz silica sand is 1000 parts by weight, the iron ore is 20wt% of the total amount of the quartz silica sand, the phenolic resin is 1wt% of the original sand, and the urotropine solution is the 20wt% of the phenolic resin, the graphite powder, zeolite powder and calcium stearate are 1wt‰ of the original sand.

[0067] The particle size of described quartz silica sand and iron ore powder is 20-300 order, and the Fe in described iron ore 3 o 4 Content ≥ 85%, 90 wt% of the particle size of the graphite powder is less than 500 mesh, the ammonia absorption of the zeolite powder is greater than 100 mmol / 100g, the particle size of the zeolite powder is 500 mesh, in the ...

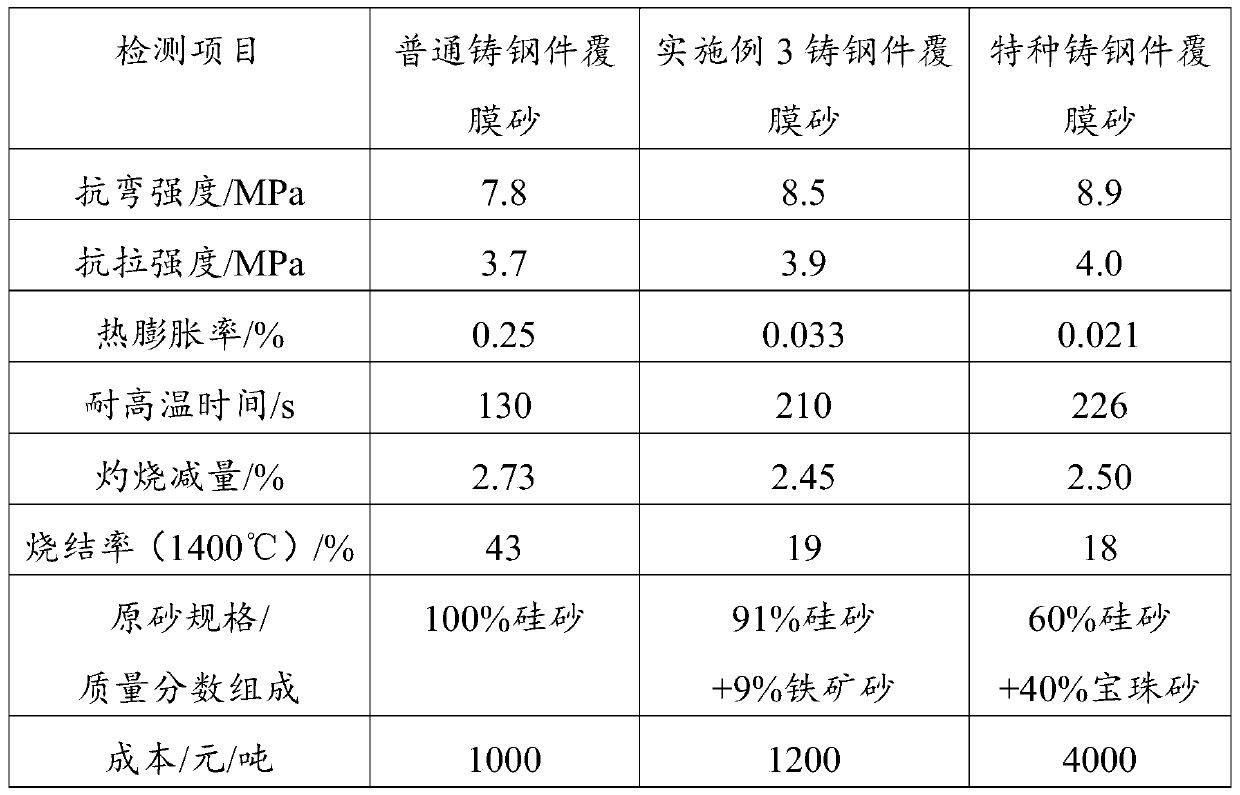

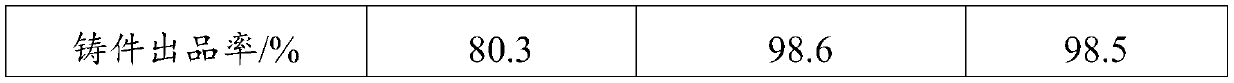

Embodiment 3

[0085] A kind of coated sand for steel castings, comprising the following raw materials: quartz silica sand, iron ore sand, zeolite powder, graphite powder, phenolic resin, silane coupling agent, urotropine solution and calcium stearate, described quartz silica sand and Iron ore is raw sand;

[0086] Wherein, the quartz silica sand is 1000 parts by weight, the iron ore is 10wt% of the total amount of the quartz silica sand, the phenolic resin is 2wt% of the original sand, and the urotropine solution is the 15wt% of the phenolic resin, and the graphite powder, zeolite powder and calcium stearate are 5wt‰ of the former sand.

[0087] The particle size of described quartz silica sand and iron ore powder is 20-300 order, and the Fe in described iron ore 3 o 4 Content ≥ 85%, 90 wt% of the particle size of the graphite powder is less than 500 mesh, the ammonia absorption of the zeolite powder is greater than 100 mmol / 100g, the particle size of the zeolite powder is 325 mesh, in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com