Silicon dioxide suspension and waterproof polymer cement slurry as well as preparation methods thereof

A technology of silica and waterproof slurry, which is applied to polymer cement waterproof slurry and its preparation, and the field of silica suspension, can solve the problems of poor performance of waterproof slurry and can not be exposed for use, poor dispersion of silica, etc. Achieve the effect of improving UV resistance, fast volatilization and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

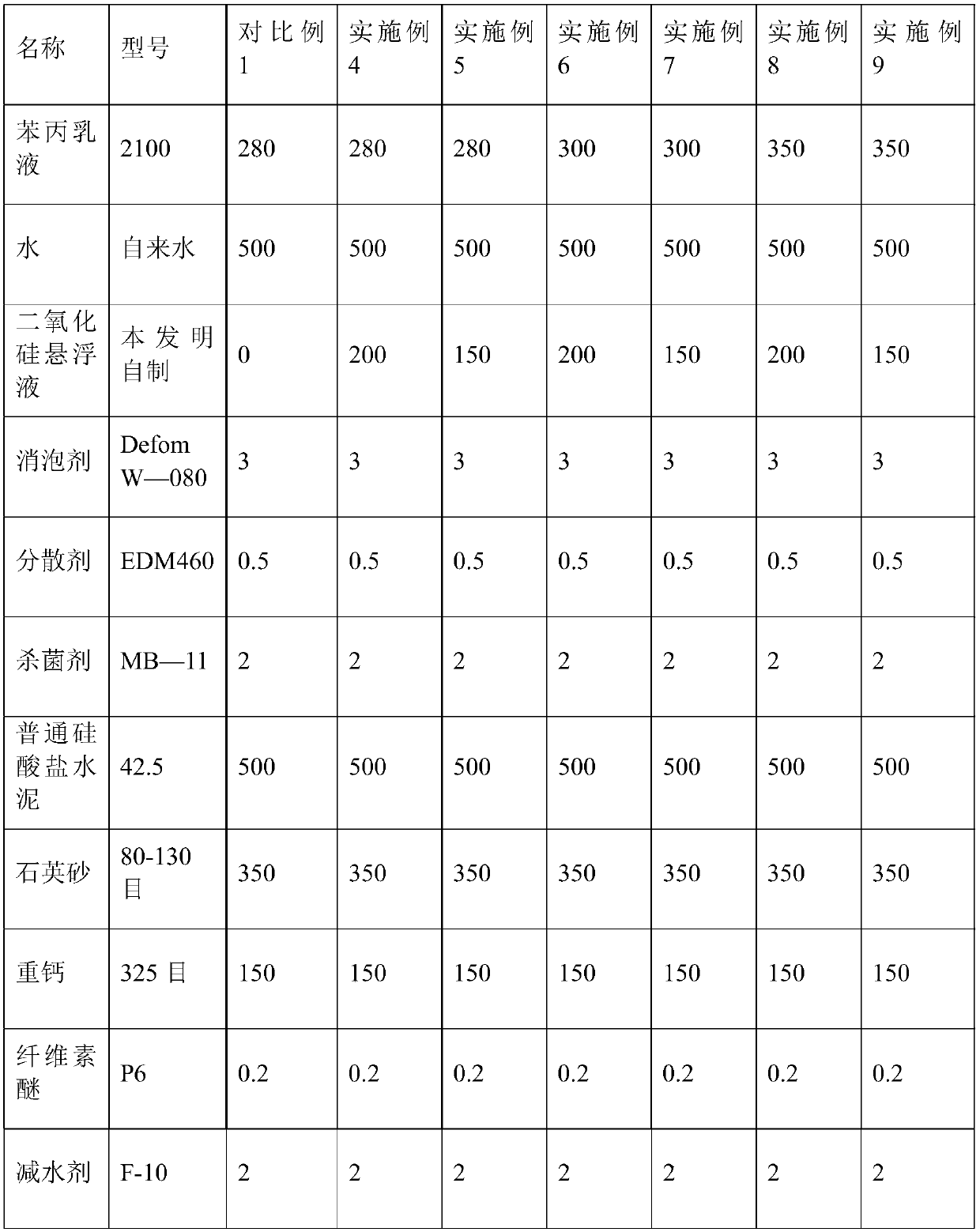

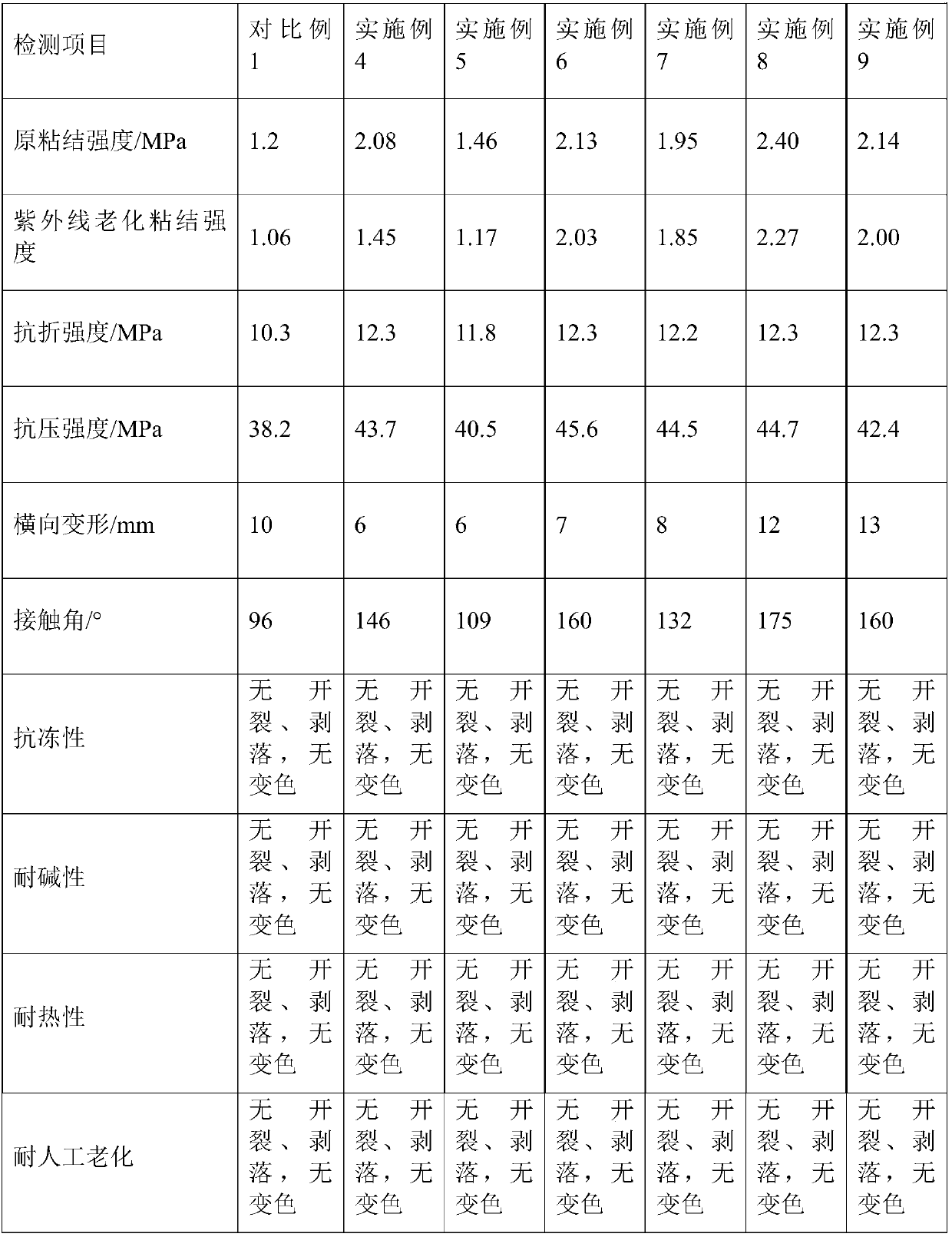

Examples

Embodiment 1

[0030] Embodiment 1 (preparation of silica suspension)

[0031] Prepare raw materials according to the formula: 276 parts of ethanol, 7 parts of ammonia water, 18 parts of deionized water, 43 parts of tetraethyl orthosilicate, 20 parts of silane coupling agent; mix the above ethanol, the above ammonia water and the above deionized water and slowly After adding into the above-mentioned tetraethyl orthosilicate (TEOS) to fully react for 1 hour, slowly add the silane coupling agent KH-550 and react for 1 hour to obtain a silica suspension.

Embodiment 2

[0032] Embodiment 2 (preparation of silica suspension)

[0033] Prepare raw materials according to the formula: 276 parts of ethanol, 10 parts of ammonia water, 18 parts of deionized water, 43 parts of tetraethyl orthosilicate, 30 parts of silane coupling agent; mix the above ethanol, the above ammonia water and the above deionized water evenly and slowly After adding into the above-mentioned tetraethyl orthosilicate (TEOS) to fully react for 1.5 hours, slowly add the silane coupling agent KH-550 and react for 1.5 hours to obtain a silica suspension.

Embodiment 3

[0034] Embodiment 3 (preparation of silica suspension)

[0035] Prepare raw materials according to the formula: 276 parts of ethanol, 14 parts of ammonia water, 18 parts of deionized water, 43 parts of tetraethyl orthosilicate, 40 parts of silane coupling agent; mix the above ethanol, the above ammonia water and the above deionized water evenly and slowly After adding into the above-mentioned tetraethyl orthosilicate (TEOS) to fully react for 2 hours, slowly add the silane coupling agent KH-550 and react for 2 hours to obtain a silica suspension.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com