Preparation method of Draxxin

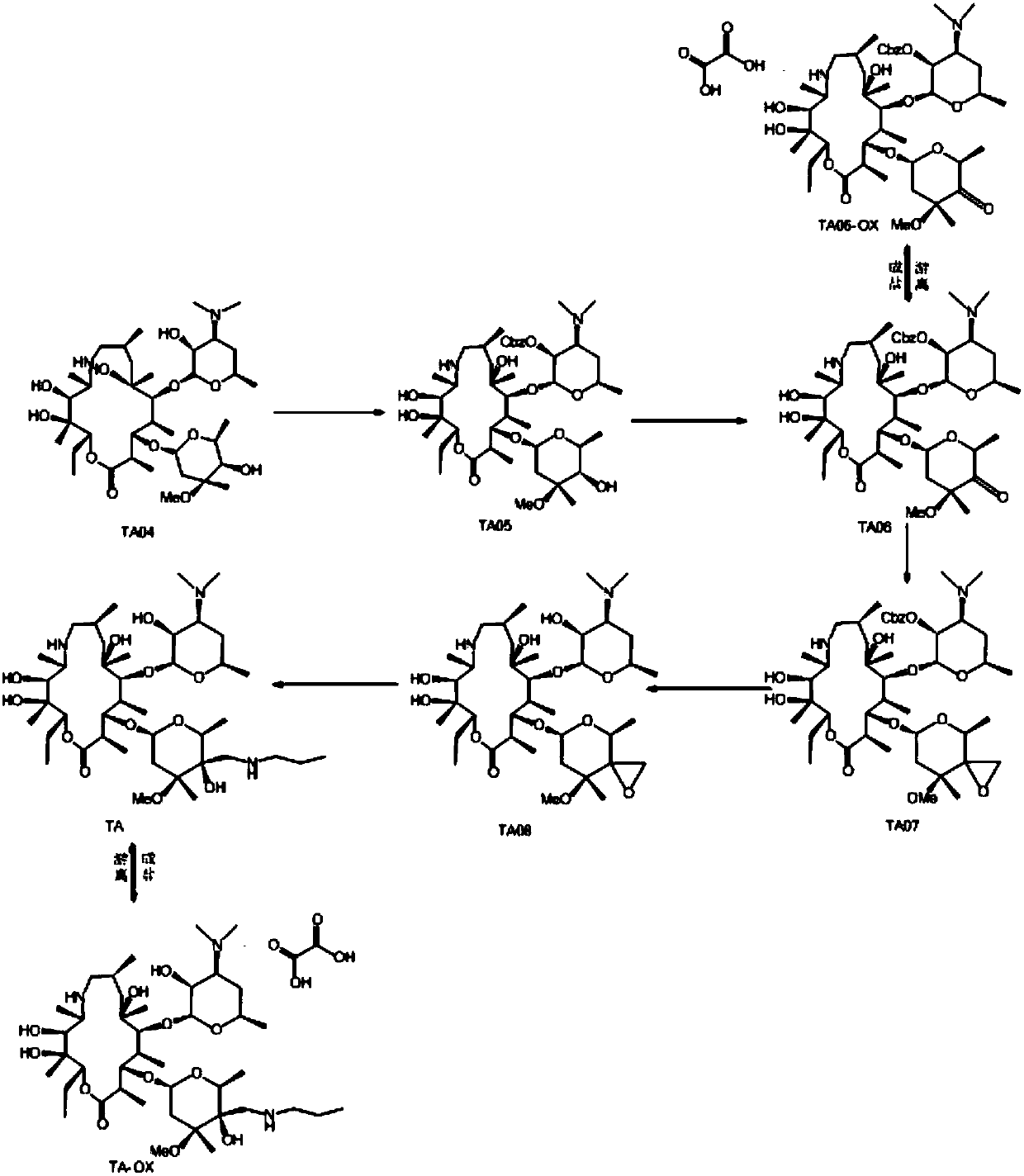

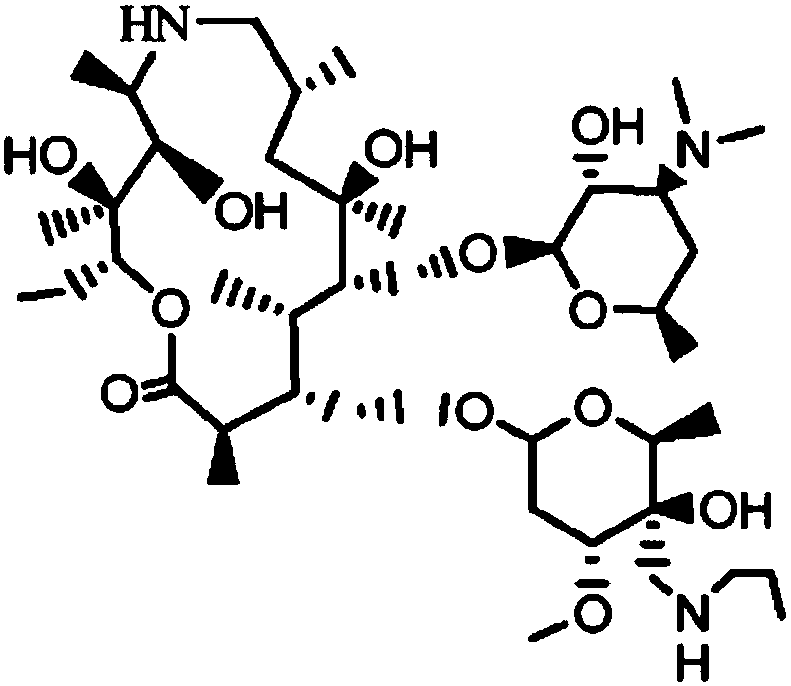

A telamectin and reagent technology, which is applied in the field of preparation of telamectin, can solve the problems of safety and cost, many reaction by-products, and low conversion rate in industrialization, and achieve ultra-low temperature reaction avoidance, good purity, and increased yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

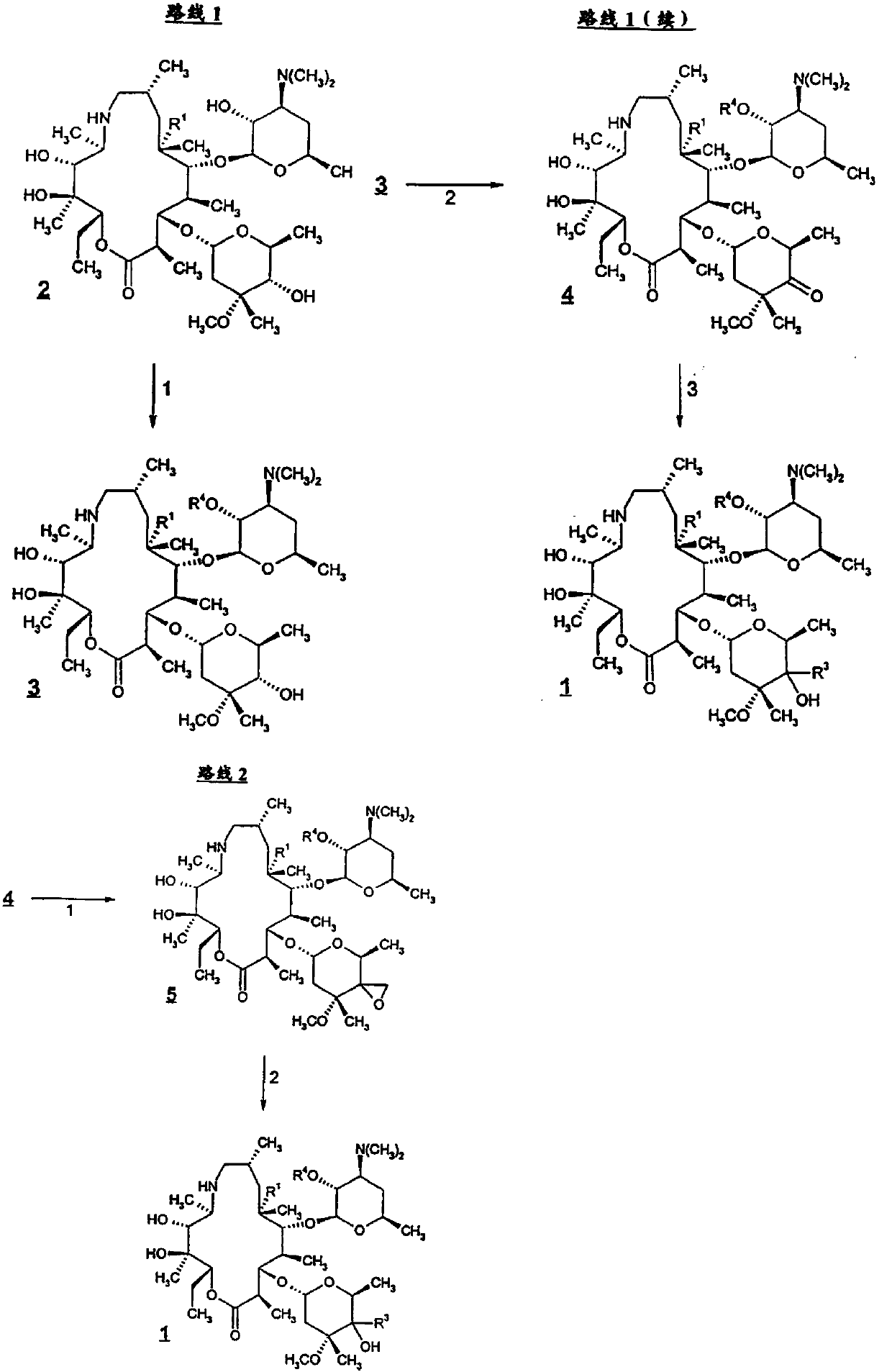

Method used

Image

Examples

Embodiment 1

[0045]The content of the invention will be further explained and illustrated below in conjunction with specific examples, but they are not intended to limit or limit the scope of the present invention. The following reagents and preparation materials are commercially available unless otherwise specified. Example 1 (comparative example, refer to patent 200510082063.7)

[0046] Put 29Kg TA04 and 160Kg dichloromethane into a 500L reactor, stir for 20-30min, put 5Kg anhydrous sodium sulfate into it, stir and dry, 1-2h, filter the whole mixture with suction, and concentrate until there is almost no fraction. Transfer the concentrated system to a 1000L reaction kettle, add 660Kg of dichloromethane at the same time, start stirring, and at the same time cool the system to -5~5°C under nitrogen protection, add 16Kg / 33Kg of benzyl chloroformate and dichloroformate dropwise to the system A solution of methyl chloride. A total of 1.5h was added dropwise, and the dropwise addition was com...

Embodiment 2

[0058] Embodiment 2 (process of the present invention)

[0059] Put 40kgTA04 and 100kg toluene into a 1000L reactor, stir for 20-30min, and concentrate at 55°C until there is no distillate. Cool down to about 25°C under the protection of nitrogen, vacuum pump 900Kg of dichloromethane, start stirring, cool down the system to -5~5°C under the protection of nitrogen, add dropwise a solution of 22kg of benzyl chloroformate and 66Kg of methylene chloride into the system . A total of about 1.5h was added dropwise, and the dropwise addition was completed. Keep warm at 0-5°C for 2-3 hours, and the conversion of raw materials is completed. (HPLC monitors the conversion of raw materials) Control the temperature T≤35°C, concentrate the reaction mixture until it becomes dry and oily, and store it at a low temperature of 0-10°C.

[0060] Add the above-mentioned TA05 and 260kgDMSO into the 500L reactor, start stirring, and after dissolving, add 18KgIBX in batches, react at 20-30°C for 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com