A kind of papaya wine and preparation method thereof

A papaya and papaya technology, applied in the food field, can solve the problems of insufficient utilization of nutrition and health care, difficulty in clarifying papaya wine, difficulty in developing papaya, etc., and achieves the effects of reasonable blending ratio, unique flavor, and clear and transparent wine body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation of embodiment 1 papaya original wine

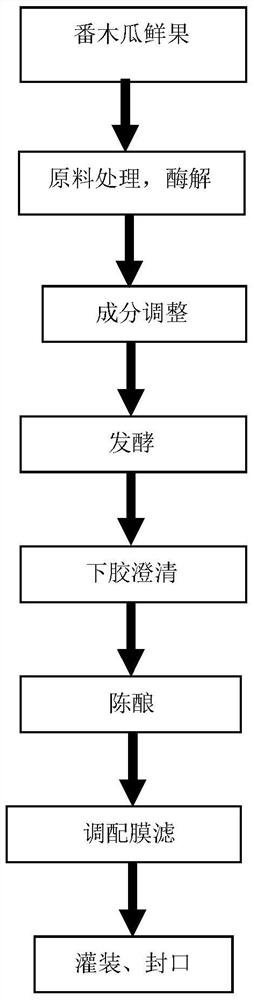

[0049] A kind of preparation method that present embodiment provides described papaya original wine, comprises the steps:

[0050] S1. Raw material processing: Choose fresh papaya fruits with 80-90% ripe yellow skin, yellow flesh or reddish color, with a sugar content of 70g / L, wash them with 30ppm sulfurous acid water, then clean them with pure water, peel and dice them. Seeds are crushed by a screw pump, and 60ppm of pectinase is added for enzymatic hydrolysis;

[0051] S2. Composition adjustment: adjust the sugar content to 220g / L at one time with white granulated sugar at the beginning of fermentation, add citric acid after complete dissolution to make the acidity 5g / L, then add sulfur dioxide 60mg / L to obtain pulp for later use;

[0052] S3. Fermentation: In the 200mg / L Angel yeast activation solution, add the same amount of activation solution to the fruit pulp and let it stand for 10 minutes, then put it int...

Embodiment 2

[0055] The preparation of embodiment 2 papaya original wine

[0056] A kind of preparation method that present embodiment provides described papaya original wine, comprises the steps:

[0057] S1. Raw material processing: Choose fresh papaya fruits with 80-90% ripe yellow skin, yellow flesh or reddish color, with a sugar content of 60g / L, wash them with 20ppm sulfurous acid water, then clean them with pure water, peel and dice them. Seeds are crushed by a screw pump, and 50ppm of pectinase is added for enzymatic hydrolysis;

[0058] S2. Composition adjustment: adjust the sugar content to 200g / L at one time with white sugar at the beginning of fermentation, add tartaric acid after complete dissolution to make the acidity 4g / L, and then add sulfur dioxide 30mg / L to obtain pulp for later use;

[0059] S3. Fermentation: In 180mg / L Angel Yeast Activation Solution, add 0.5 times fruit pulp and let it stand for 5 minutes, then put it into the tank for fermentation. When the ferment...

Embodiment 3

[0062] The preparation of embodiment 3 papaya original wine

[0063] A kind of preparation method that present embodiment provides described papaya original wine, comprises the steps:

[0064] S1. Raw material processing: Choose fresh papaya fruits with 80-90% ripe yellow skin, yellow flesh or reddish color, with a sugar content of 75g / L, wash them with 60ppm sulfurous acid water, then clean them with pure water, peel and dice them. Seeds are crushed by a screw pump, and 150ppm of pectinase is added for enzymatic hydrolysis;

[0065] S2. Composition adjustment: adjust the sugar content to 240g / L at one time with white sugar at the beginning of fermentation, add citric acid after complete dissolution to make the acidity 10g / L, then add sulfur dioxide 60mg / L to obtain pulp for later use;

[0066] S3. Fermentation: In the 240mg / L Angel Yeast Activation Solution, add 3 times the fruit pulp and let it stand for 20 minutes, then put it into the tank for fermentation. When the ferm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com