Method for growing magnetic two-dimensional VSe2 thin film at room temperature through chemical vapor deposition

A technology of chemical vapor deposition and growth method, which is applied in the field of chemical vapor deposition (CVD) growth of magnetic two-dimensional VSe2 thin film at room temperature, which can solve the problems of complex steps and achieve the effects of simplified synthesis steps, easy adjustment, and realization of size and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

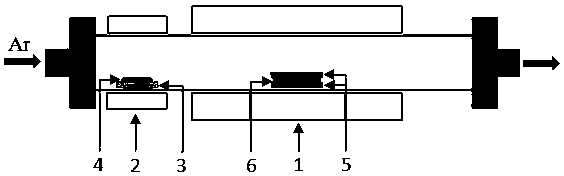

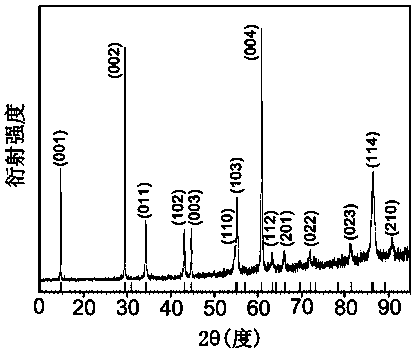

[0034] Room temperature magnetic two-dimensional VSe 2 thin film CVD growth

[0035] Step 1: Substrate cutting

[0036] Carve the polished sapphire substrate into a rectangle of 2 cm × 1 cm with a diamond knife for pen test.

[0037] Step 2: substrate cleaning.

[0038] (1) Put the polished side of the sapphire substrate 5 into a beaker filled with acetone, ethanol and deionized water to clean in sequence. Ultrasound in the device for 20min;

[0039] (2) Dry the cleaned sapphire substrate 5 with a nitrogen gun.

[0040] Step 3: Weighing the mass of the Se precursor

[0041] (1) Put a 3 cm long quartz boat 3 into the balance and peel it back to zero, put selenium powder 4 with a purity of 99.99% into the quartz boat 3 with a medicine spoon, and weigh 300 mg with an electronic balance;

[0042] (2) Put the quartz boat 3 filled with Se powder into the center of the external heating belt located upstream of the CVD tube furnace 1, and the distance between the center of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com