Nickel, cobalt, lithium manganate core-shell material gel and preparation method therefor

A lithium manganate, core-shell technology, applied in nickel, lithium manganate core-shell material gel and its preparation, cobalt field, can solve problems such as poor environmental tolerance, achieve improved cycle, improved stability, good environmental resistance. receptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0035] (1) Preparation of metal salt solution I: According to the molar ratio of metal ions Ni:Co:Mn:Mg is 8:1:0.9:0.1, take nickel acetate tetrahydrate, cobalt acetate tetrahydrate, manganese acetate tetrahydrate and magnesium nitrate solution Prepare 0.5mol / L metal salt solution in 500ml deionized water.

[0036] (2) Preparation of sol I: add 100ml of lithium hydroxide solution with a mass fraction of 5.92% and 50ml of citric acid solution with a mass fraction of 34.44% into the metal salt solution in a sequential manner, and stir at room temperature for 5 hours to form a sol .

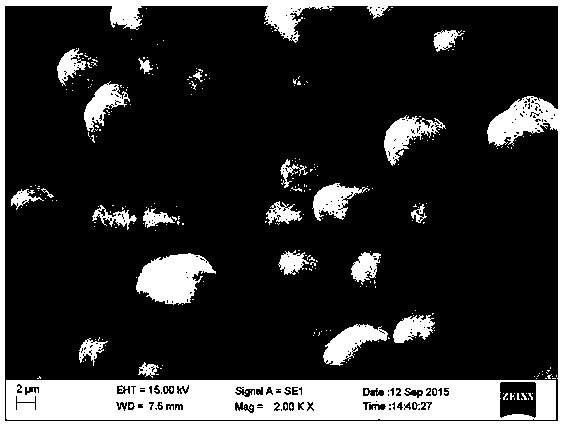

[0037] (3) Preparation of spherical spheroidized precursor Ⅰ: Sol Ⅰ was heated in a water bath at 80°C for 4 hours to obtain gelled precursor Ⅰ, and the gelled precursor was crushed by sand milling, and spheroidized precursor Ⅰ was prepared by spheroidization technology.

[0038] (4) Precursor II preparation: according to the molar ratio of metal ions Ni:Co:Mn:Mg is 6:3:0.9:0.1, nickel acetate tetr...

Embodiment example 2

[0043] (1) Preparation of metal salt solution I: according to the molar ratio of metal ions Ni:Co:Mn:Mg is 8:1:0.95:0.05, weigh nickel nitrate, cobalt nitrate, manganese nitrate, magnesium nitrate and dissolve in 500ml deionized water Prepare 0.5mol / L metal salt solution.

[0044] (2) Preparation of sol I: add 100ml of lithium hydroxide solution with a mass fraction of 5.92% and 50ml of citric acid solution with a mass fraction of 34.44% into the metal salt solution in a sequential manner, and stir at room temperature for 5 hours to form a sol .

[0045] (3) Preparation of spherical spheroidized precursor Ⅰ: Sol Ⅰ was heated in a water bath at 80°C for 4 hours to obtain gelled precursor Ⅰ, and the gelled precursor was crushed by sand milling, and spheroidized precursor Ⅰ was prepared by spheroidization technology.

[0046] (4) Precursor II preparation: According to the molar ratio of metal ions Ni:Co:Mn:Mg is 6:3:0.95:0.05, nickel nitrate, cobalt nitrate, manganese nitrate, m...

Embodiment example 3

[0052] (1) Preparation of metal salt solution I: according to the molar ratio of metal ions Ni:Co:Mn:Mg is 8:1:0.95:0.05, take nickel acetate tetrahydrate, cobalt acetate tetrahydrate, manganese acetate tetrahydrate and magnesium nitrate solution Prepare 0.5mol / L metal salt solution in 500ml deionized water.

[0053] (2) Preparation of sol I: add 100ml of lithium hydroxide solution with a mass fraction of 5.92% and 50ml of citric acid solution with a mass fraction of 34.44% into the metal salt solution in a sequential manner, and stir at room temperature for 5 hours to form a sol .

[0054] (3) Preparation of spherical spheroidized precursor Ⅰ: Sol Ⅰ was heated in a water bath at 80°C for 4 hours to obtain gelled precursor Ⅰ, and the gelled precursor was crushed by sand milling, and spheroidized precursor Ⅰ was prepared by spheroidization technology.

[0055] (4) Precursor II preparation: according to the molar ratio of metal ions Ni:Co:Mn:Mg is 6:3:0.95:0.05, nickel acetate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com