Composite material for preparing hydrogen energy source by decomposition water under visible light and its preparation method

A technology for composite materials and water splitting, which is applied in the field of composite materials and its preparation, can solve problems such as poor stability, narrow photoresponse range, and low hydrogen production rate, and achieve wide response range, good repeatability, and high photocatalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

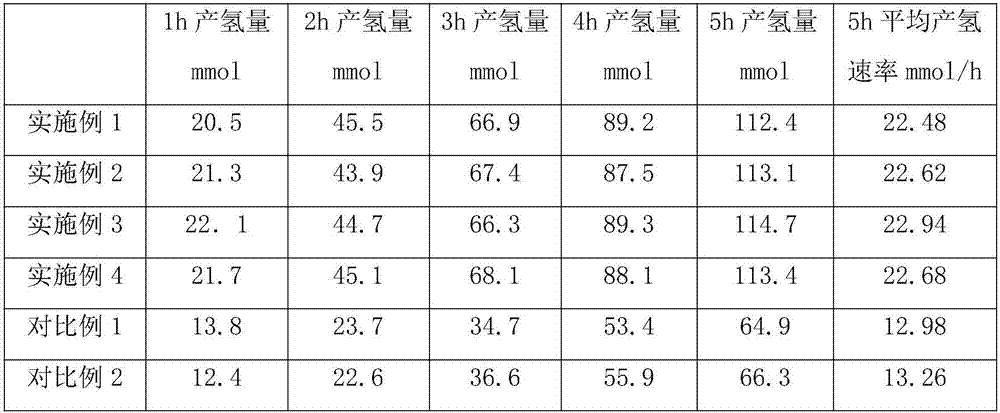

Examples

Embodiment 1

[0026] A method for preparing a composite material for decomposing water under visible light to prepare hydrogen energy, comprising the following steps:

[0027] (1) 0.23g Zn(Ac) 2 2H 2 O, 0.3gIn(NO 3 ) 3 1. Add 0.6g of cerium nitrate to 100ml of ethanol solution, stir for 45min at a temperature of 70°C, then add 0.03g of thioacetamide, and continue stirring for 2h before use;

[0028] (2) Under constant stirring, add 50ml of 2mg / mL graphene oxide solution to the solution in step (1), and after stirring for 60min, transfer the resulting mixture to the reactor, react at a temperature of 160°C for 18h, and stop the reaction Afterwards, the reactor was cooled to room temperature, washed with water until neutral to obtain product A;

[0029] (3) Add 0.3g In(NO 3 ) 3 , 0.23g Cd(Ac) 2 2H 2 O. Add 0.6 g of cerium nitrate to 100 ml of ethanol solution, stir for 40 min at a temperature of 80° C., then add 0.03 g of thioacetamide, and continue stirring for 2 h for later use;

...

Embodiment 2

[0033] A method for preparing a composite material for decomposing water under visible light to prepare hydrogen energy, comprising the following steps:

[0034] (1) 0.23g Zn(Ac) 2 2H 2 O, 0.32gIn(NO 3 ) 3 1. Add 0.65g of cerium nitrate to 100ml of ethanol solution, stir for 45min at a temperature of 70°C, then add 0.05g of thioacetamide, and continue stirring for 2h before use;

[0035](2) Under constant stirring, add 60ml of 2mg / mL graphene oxide solution to the solution in step (1), and after stirring for 60min, transfer the resulting mixture to a reaction kettle, react at a temperature of 180°C for 15h, and stop the reaction Afterwards, the reactor was cooled to room temperature, washed with water until neutral to obtain product A;

[0036] (3) 0.32g In(NO 3 ) 3 , 0.23g Cd(Ac) 2 2H 2 O. Add 0.65 g of cerium nitrate to 100 ml of ethanol solution, stir for 40 min at a temperature of 80° C., then add 0.05 g of thioacetamide, and continue stirring for 2 h for later use...

Embodiment 3

[0040] A method for preparing a composite material for decomposing water under visible light to prepare hydrogen energy, comprising the following steps:

[0041] (1) 0.3g Zn(Ac) 2 2H 2 O, 0.4gIn(NO 3 ) 3 1. Add 0.7g of cerium nitrate to 100ml of ethanol solution, stir for 45min at a temperature of 70°C, then add 0.06g of thioacetamide, and continue stirring for 2h before use;

[0042] (2) Under constant stirring, add 80ml of 2mg / mL graphene oxide solution to the solution in step (1), and after stirring for 60min, transfer the resulting mixture to the reactor, react at a temperature of 160°C for 18h, and stop the reaction Afterwards, the reactor was cooled to room temperature, washed with water until neutral to obtain product A;

[0043] (3) Add 0.4g In(NO 3 ) 3 , 0.3g Cd(Ac) 2 2H 2 O. Add 0.7 g of cerium nitrate to 100 ml of ethanol solution, stir for 40 min at a temperature of 80° C., then add 0.06 g of thioacetamide, and continue stirring for 2 h for later use;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com