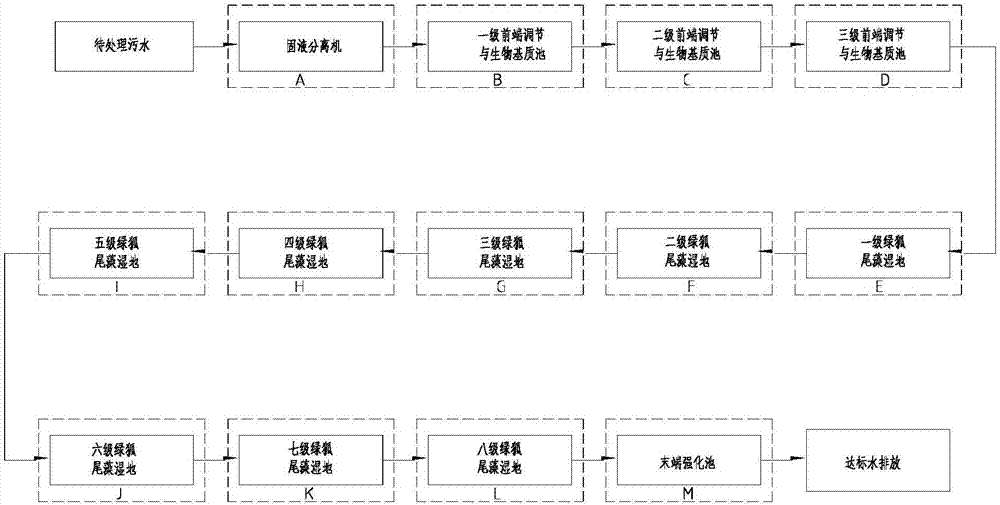

Method and system for carrying out ecological treatment on breeding wastewater from pig farms

A technology for breeding wastewater and pig farms, applied in the field of agricultural environment, can solve the problems of water pollution, content increase, large power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A pig farm was established in Fendong Village, Longkou Town, Heshan City, Jiangmen City, Guangdong Province, Heshan Xinhao Agriculture and Animal Husbandry Co., Ltd. The ecological treatment system for viridiflorium polluted by farming wastewater started construction on December 3, 2016. On January 14, 2017, straw was filled in the front-end adjustment and biological matrix treatment tanks respectively, and clear water was released in the ecological wetland (add about 1% for breeding Wastewater) after planting Chrysopsis viridis, spraying Red Junbao No. 6 in the front-end adjustment and biological matrix treatment pool and ecological wetland respectively on January 27, 2017; on February 14, the aquaculture wastewater was connected to the system. According to a total of 8 test results between February 28, 2017 and July 20, 2017, the COD content in the aquaculture wastewater (after solid-liquid separation) was 7130-9210mg / L, the ammonia nitrogen content was 1242-1791mg / L, ...

Embodiment 2

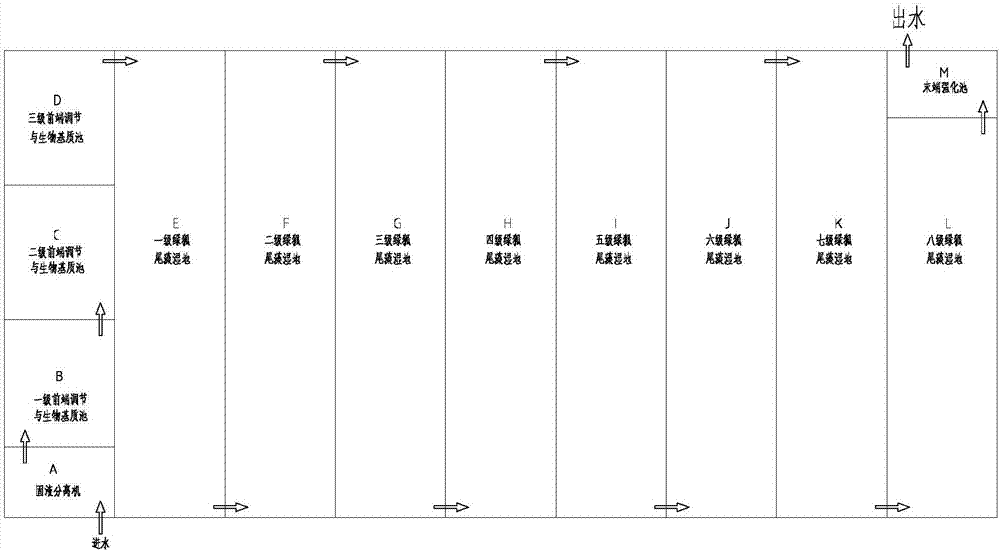

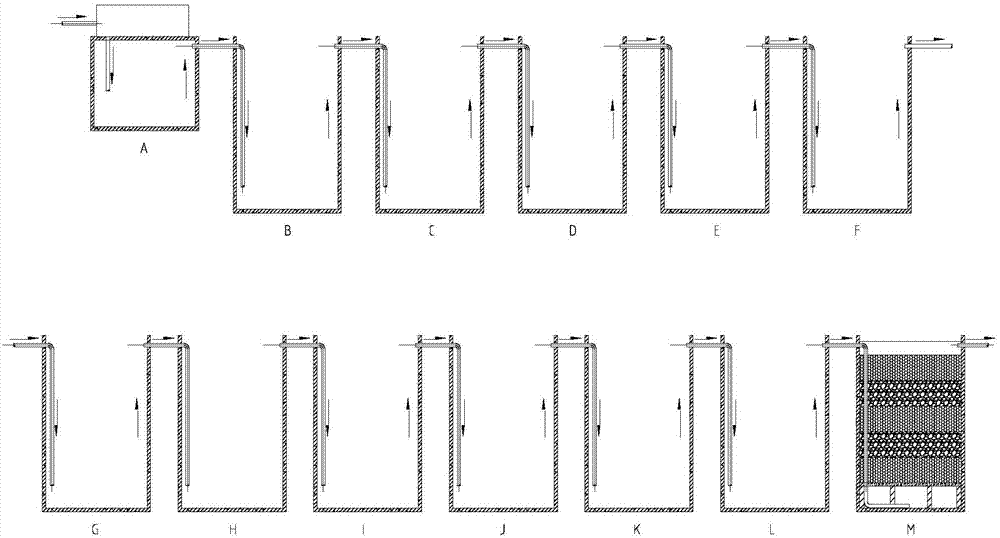

[0077] A system for ecological treatment of pig farm wastewater, which consists of solid-liquid separation equipment, a first-level front-end adjustment and biomass purification pool, a second-level front-end adjustment and biomass purification pool, a third-level front-end adjustment and biomass purification pool, four Level front-end adjustment and biomass purification pool, level 1 ecological wetland, level 2 ecological wetland, level 3 green ecological wetland, level 4 ecological wetland, level 5 ecological wetland, level 6 ecological wetland, level 7 ecological wetland, and terminal enhanced treatment pool , characterized in that: the solid-liquid separation equipment is connected to the first-level front-end adjustment and the biomass purification tank through pipelines, the aquaculture wastewater is separated from the solid-liquid, and the wastewater enters the first-level front-end adjustment and biomass purification tank through the pipeline, and the first-level front-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com