Modified cement polystyrene mold shell building block and processing process thereof

A technology of polystyrene formwork and cement, which is applied to building components, heat preservation, fire protection, etc., can solve the problems of short service life, cracking and water seepage, poor safety performance, etc., to improve durability, prolong service life, meet heat preservation performance and The effect of refractory properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0021] A modified cement polyphenyl formwork block, including the following components per unit volume: 230-320 kg of high-grade Portland cement, 6-12 kg of graded polystyrene particles, 0-90 kg of secondary fly ash, and acrylic acid High molecular polymer waterproofing agent 4~12kg, water 120~170kg.

[0022] A processing technology for modified cement polystyrene formwork blocks, comprising the steps of:

[0023] ⑴Weigh and equip the required raw material components according to the above formula;

[0024] ⑵Use the light aggregate forced mixer to mix the prepared raw materials evenly;

[0025] ⑶ Utilize a pressure molding machine to mold the uniformly mixed raw materials;

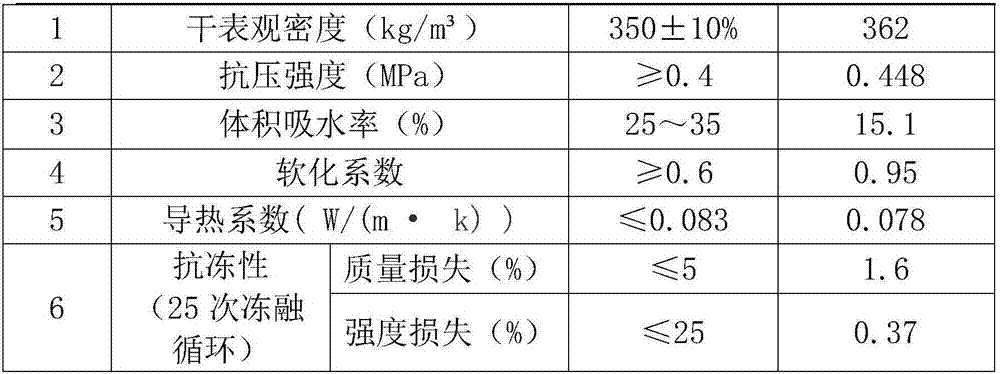

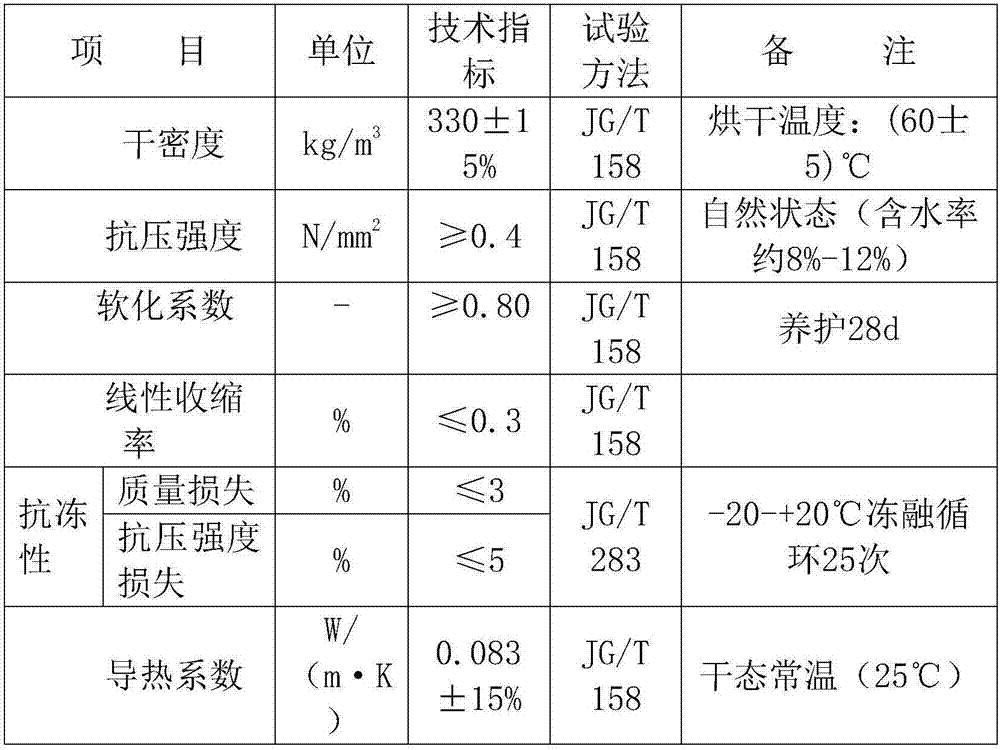

[0026] ⑷The molded raw materials are naturally cured for 28 days to make semi-finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com