Preparation method of nanocellulose/filter paper composite filter membrane material

A technology of nanocellulose and composite filtration, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve problems such as high cost and complicated preparation process, achieve low production cost, improve adsorption and filtration capacity, and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

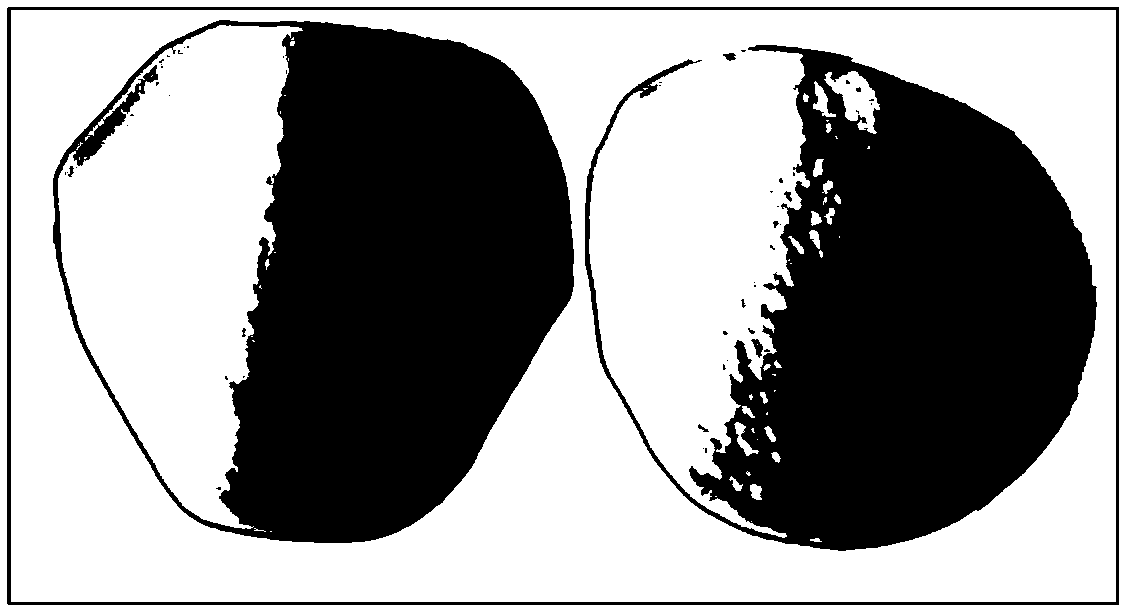

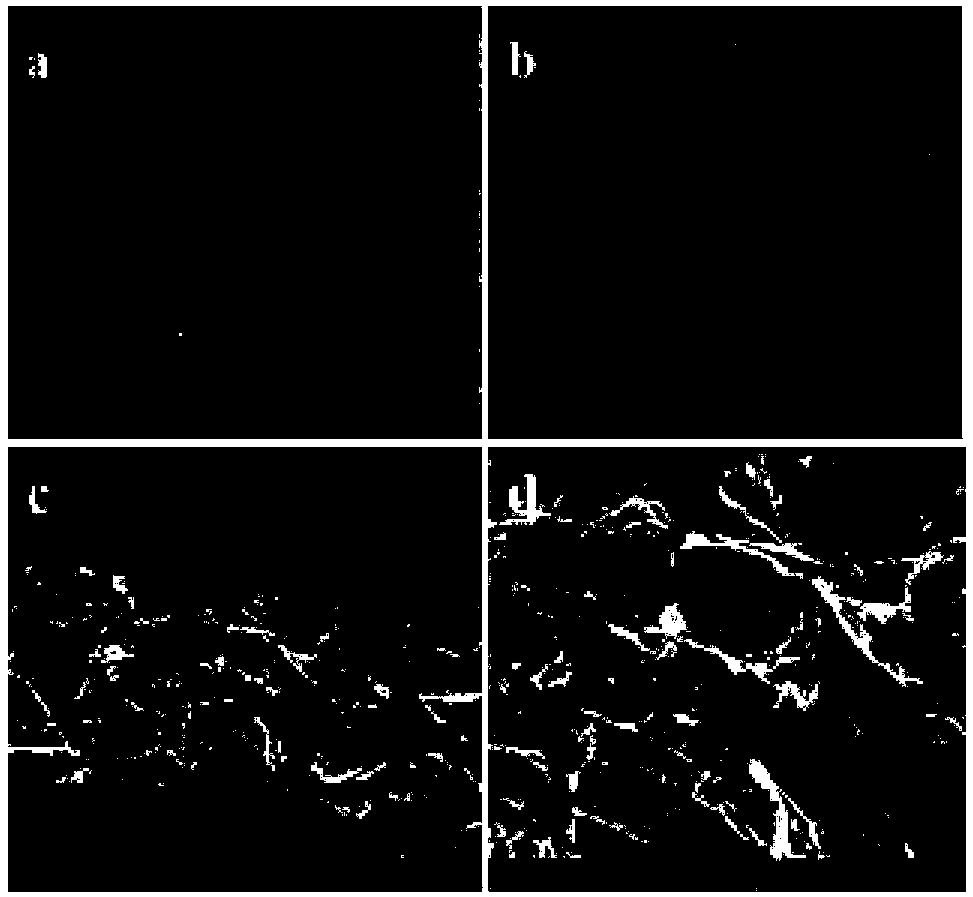

Image

Examples

Embodiment 1

[0033] The preparation method of nanocellulose / filter paper composite filter membrane material, concrete steps are as follows:

[0034] 1) Preparation of nanocellulose dispersion

[0035] Weigh 1g of dry weight cellulose sample of hardwood bleached wood pulp, 0.1g of sodium bromide, 0.016g of TEMPO and 100mL of distilled water into a beaker, stir evenly, and fully dissolve. Add 6 mmol sodium hypochlorite to the system, add dropwise 5M hydrochloric acid to adjust the overall system pH to 10, and start oxidation. Use MM-60R type automatic titrator to automatically drop 0.5M sodium hydroxide solution to maintain the overall system pH at 10. When the system hardly consumes the sodium hydroxide solution, add a small amount of absolute ethanol to terminate the reaction, add 0.5M hydrochloric acid to adjust the pH to neutral, and obtain oxidized cellulose for use. Take 0.1g dry weight of oxidized cellulose and add it into 100mL distilled water for homogenization, ultrasonic operati...

Embodiment 2

[0041] The preparation of nanocellulose / filter paper composite filter membrane material, the method is the same as in Example 1, wherein, in step 1), the bleached wood pulp of the cellulose sample broad-leaved wood adopts softwood bleached wood pulp, bleached straw pulp, or bleached bamboo pulp. an alternative.

Embodiment 3

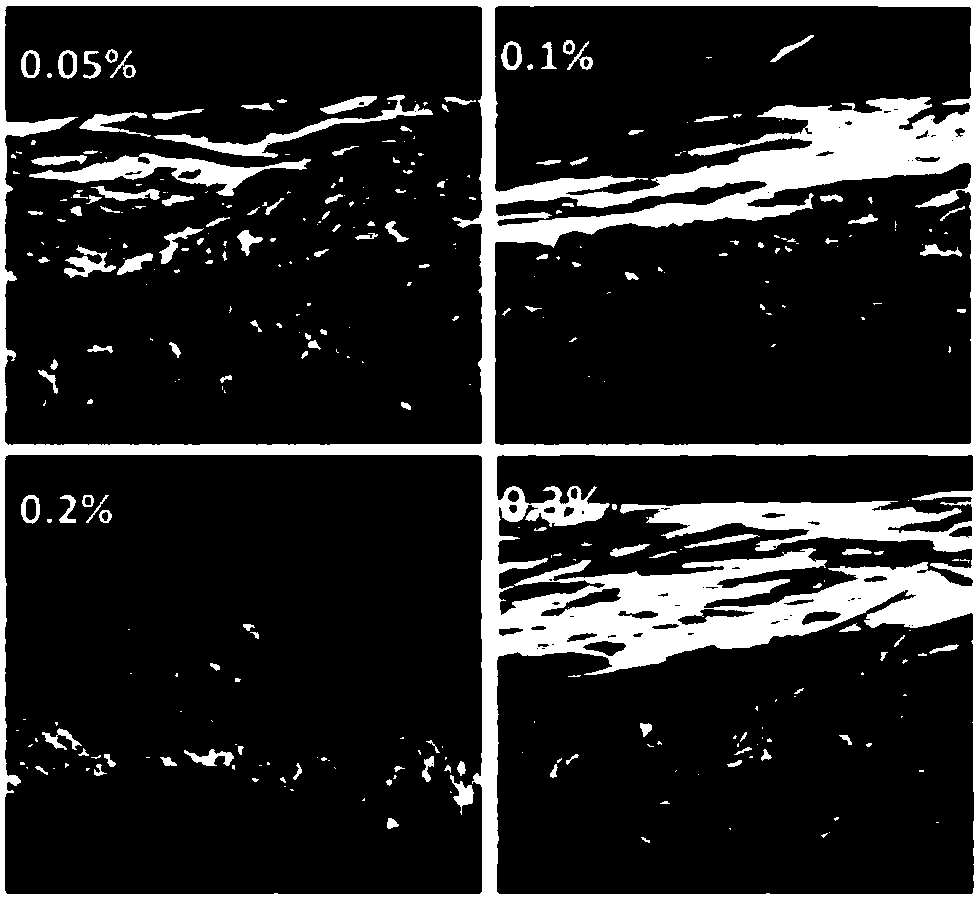

[0043] The preparation of nanocellulose / filter paper composite filter membrane material, the method is the same as in Example 1, wherein, in step 2), the nanocellulose dispersion with a concentration of 0.05% adopts a concentration of 0.1%, 0.2%, and 0.3% nanocellulose Either of the dispersions can be substituted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com