Oxygen reduction catalyst, preparation method and application thereof

A catalyst and nitrogen-doped carbon technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as easy agglomeration, difficult repetition, low surface area, etc., to promote catalytic reactions, Raw materials are readily available and the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

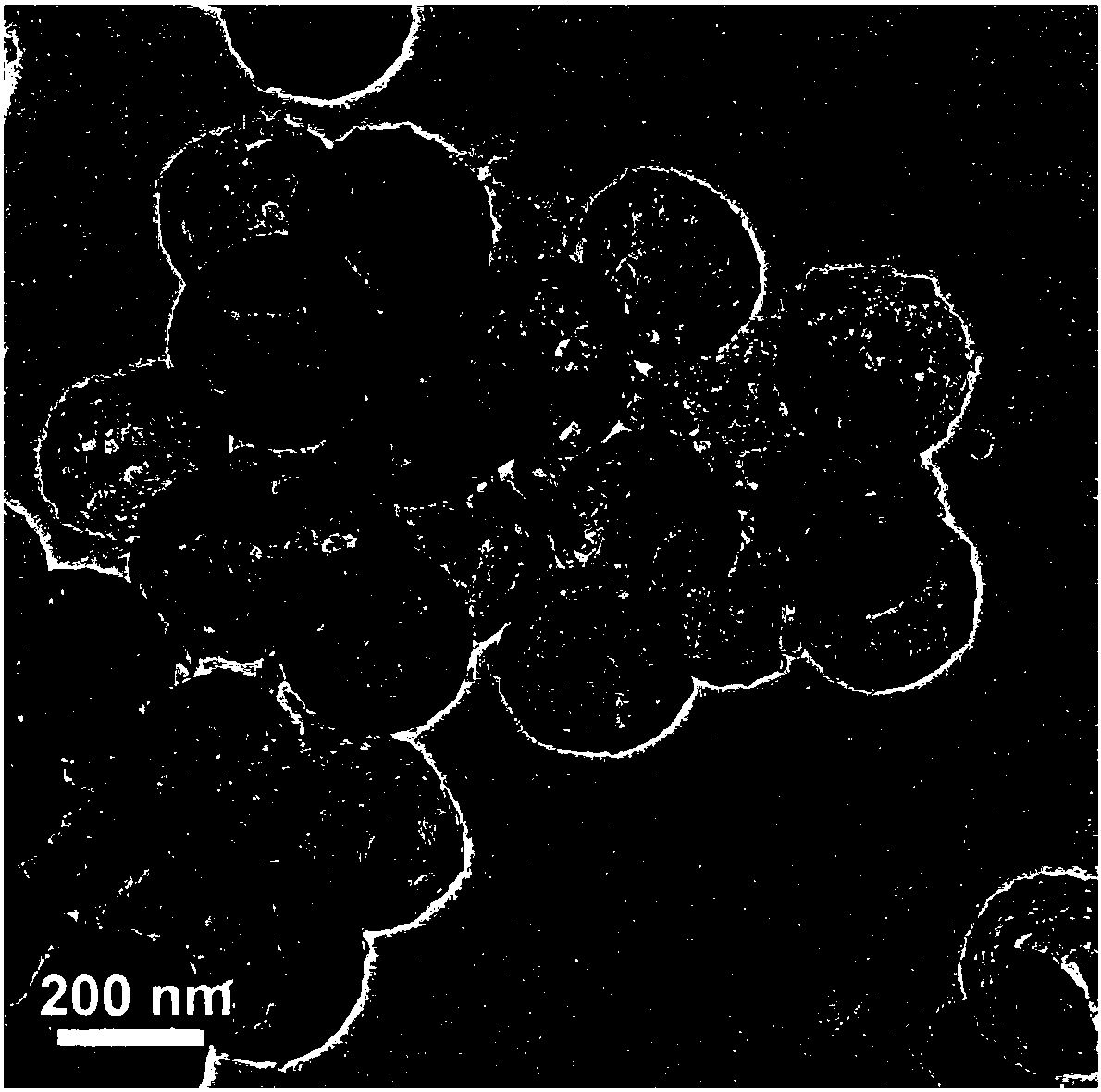

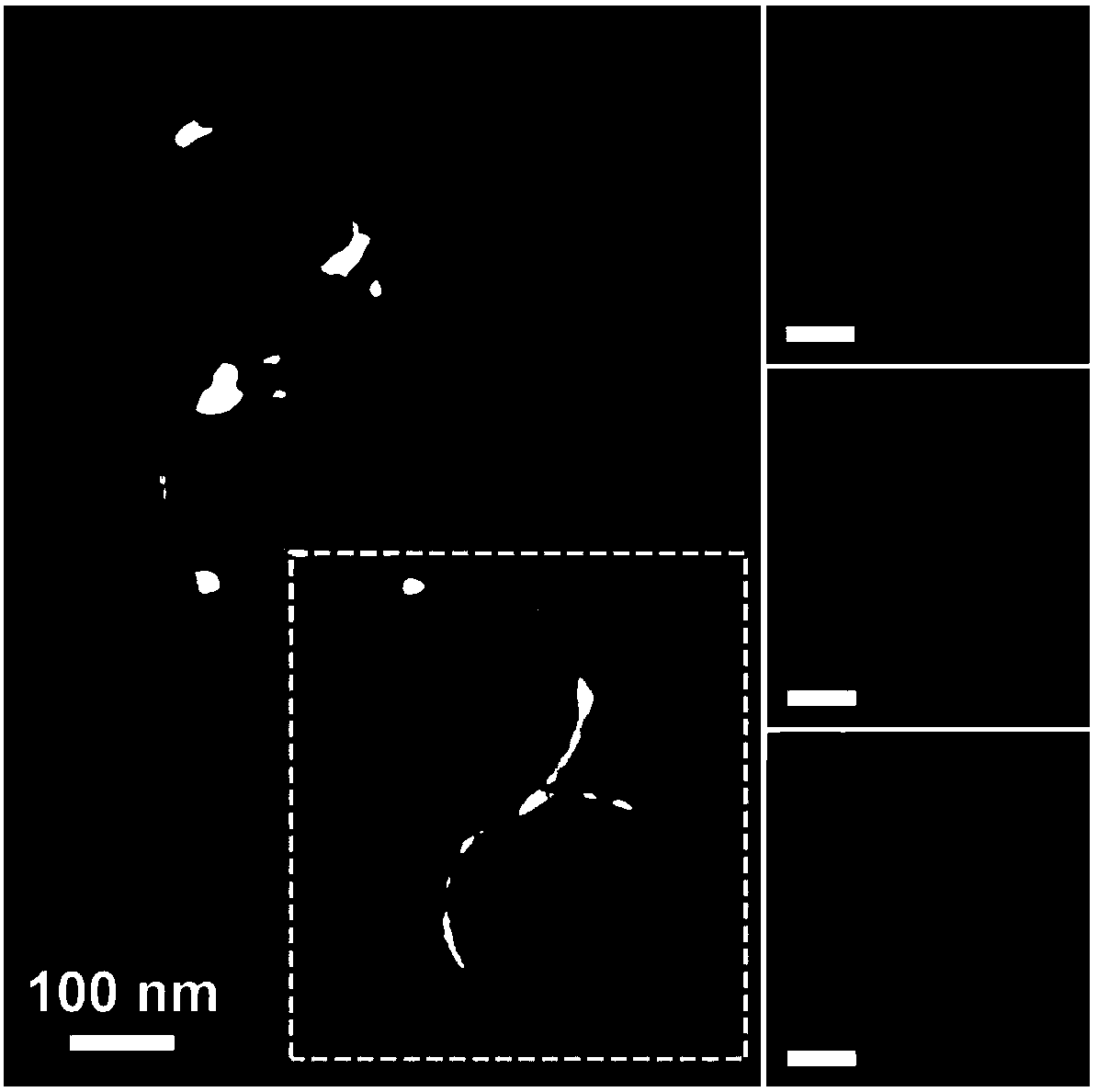

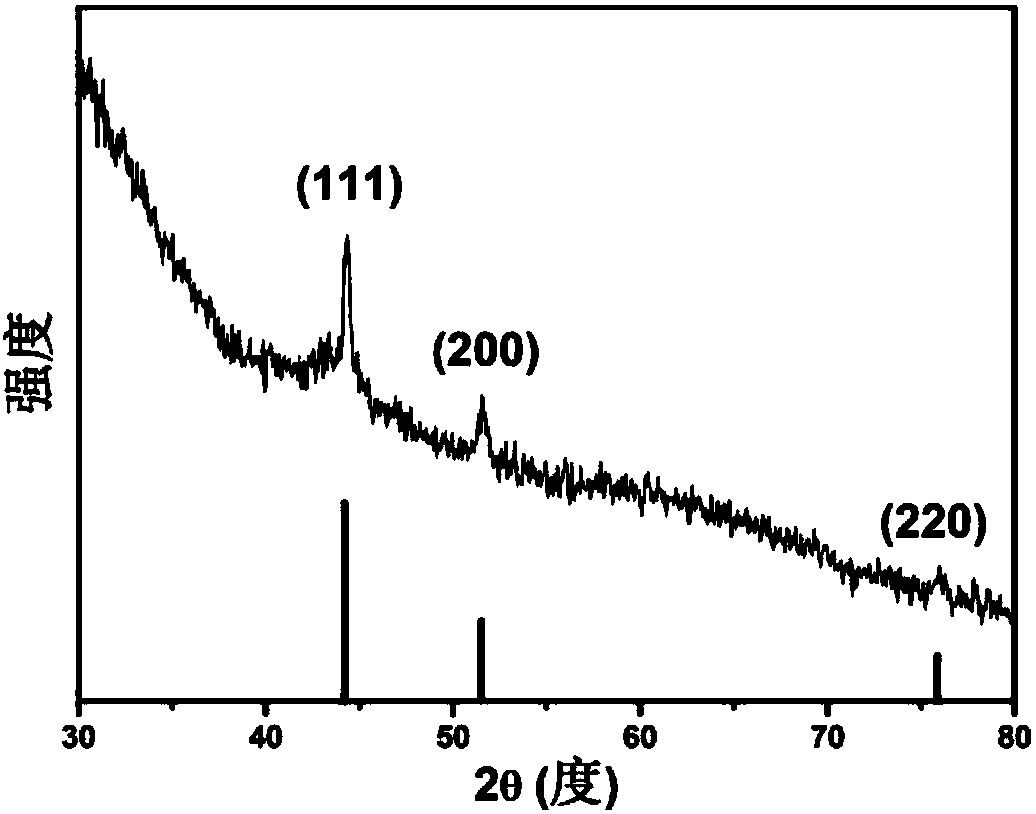

[0038] This embodiment discloses an oxygen reduction catalyst, which includes a hollow nitrogen-doped carbon sphere with a shell, and transition metal nanoparticles embedded in the shell; the shell also has mesopores penetrating inside and outside Pore channel, the average pore diameter of the mesoporous channel is 3.8nm.

[0039] Specifically, in this embodiment, the transition metal nanoparticles are cobalt nanoparticles, and the average particle size of the cobalt nanoparticles is 20 nm.

[0040] More specifically, the particle size of the hollow nitrogen-doped carbon sphere is 290nm, and the thickness of the shell is 20nm; the specific surface area of the oxygen reduction catalyst is 340m 2 / g.

[0041] It is worth noting that the material of the shell in the oxygen reduction catalyst of this embodiment is nitrogen-doped carbon, which has a graphene-like structure; that is, when the shell is in an unfolded state, it is a two-dimensional layered structure, and the she...

Embodiment 2

[0044] Example 2 is intended to describe in detail the preparation method of the oxygen reduction catalyst in Example 1 above.

[0045] The preparation method of the oxygen reduction catalyst according to the present embodiment comprises the following steps:

[0046] In step S1, the microsphere template is dispersed in the alkaline solution to obtain a first mixture.

[0047] In this embodiment, the microsphere template is specifically a polystyrene microsphere template, and the alkaline solution is trishydroxymethylaminomethane aqueous solvent; but the present invention is not limited thereto, and the microsphere template is also Can be other templates such as polyacrylate microspheres, polyurethane microspheres, etc., as long as the materials can be thermally decomposed at a higher temperature (such as 700 ° C ~ 1000 ° C); the alkaline solution can also be such as At least one of aqueous ammonia solution, aqueous sodium hydroxide solution, aqueous potassium hydroxide soluti...

Embodiment 3

[0059] Example 3 is intended to describe the application of the oxygen reduction catalyst described in Example 1 in the cathode of a fuel cell.

[0060] The application of the oxygen reduction catalyst according to this embodiment in the cathode of the fuel cell specifically refers to the following steps:

[0061] In step Q1, the oxygen reduction catalyst is dispersed in an aqueous solution of ethanol to obtain a first solution.

[0062] Specifically, the mass of the oxygen reduction catalyst in Example 1 used in this example is 5 mg, and the aqueous ethanol solution used to disperse the oxygen reduction catalyst is prepared by mixing 765 μL of water and 200 μL of ethanol.

[0063] In step Q2, a perfluorosulfonic acid solution is added to the first solution to obtain a first slurry.

[0064] Specifically, the amount of perfluorosulfonic acid solution used was 35 μL.

[0065] Preferably, after adding the perfluorosulfonic acid solution to the first solution, sonicate for 40 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com