Hybrid spheres capable of removing Br ions from drinking water as well as preparation method and application of hybrid spheres

A bromide ion and drinking water technology, applied in chemical instruments and methods, ion exchange water/sewage treatment, water pollutants, etc., can solve the problems of small water throughput, large consumption of iron powder, high cost, etc., and achieve continuous Optimized production, improved circulation efficiency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of silver algae gel: preparation of silver nitrate-sodium alginate sol with a mass ratio of silver nitrate:sodium alginate=1:10 and a mass concentration of 5%; 24h;

[0035] (2) Molding: molding the aged silver nitrate-sodium alginate sol into 3mm pellets through a mold, and reacting in 12% calcium chloride solution at 45°C for 5 hours;

[0036] (3) Purification and removal of impurities: the hybrid pellets obtained in step (2) are washed with water until they are free of calcium ions and chloride ions, and then they are centrifuged, dehydrated, and packaged to obtain a hybrid pellet composed of calcium alginate / AgCl material. small ball;

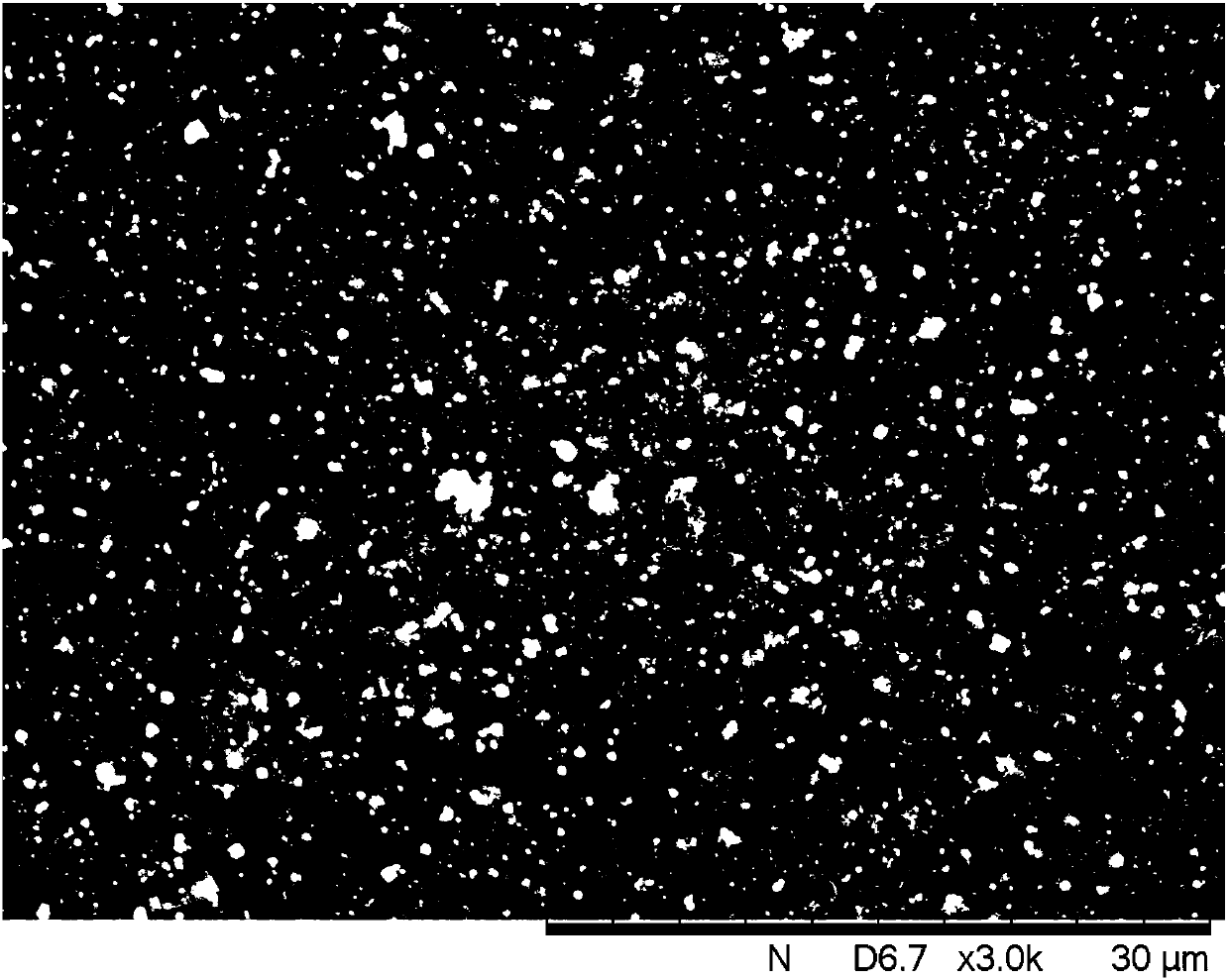

[0037] The prepared calcium alginate / AgCl hybrid pellets were characterized by SEM, and the results are shown in figure 1 As shown, it can be seen that calcium alginate forms a continuous phase, and white silver chloride particles are evenly distributed in the continuous phase of calcium alginate to be "embedded" an...

Embodiment 2

[0042] (1) Preparation of silver algae gel: prepare a silver nitrate-sodium alginate sol with a mass ratio of silver nitrate:sodium alginate=1:5 and a mass concentration of 1%; keep the silver nitrate-sodium alginate sol dark 10h;

[0043] (2) Molding: mold the aged silver nitrate-sodium alginate sol into 5mm pellets, and react in 30% calcium chloride solution at 60°C for 0.5h;

[0044] (3) Purification and removal of impurities: the hybrid pellets obtained in step (2) are washed with water until they are free of calcium ions and chloride ions, and then they are centrifuged, dehydrated, and packaged to obtain a hybrid pellet composed of calcium alginate / AgCl material. small ball;

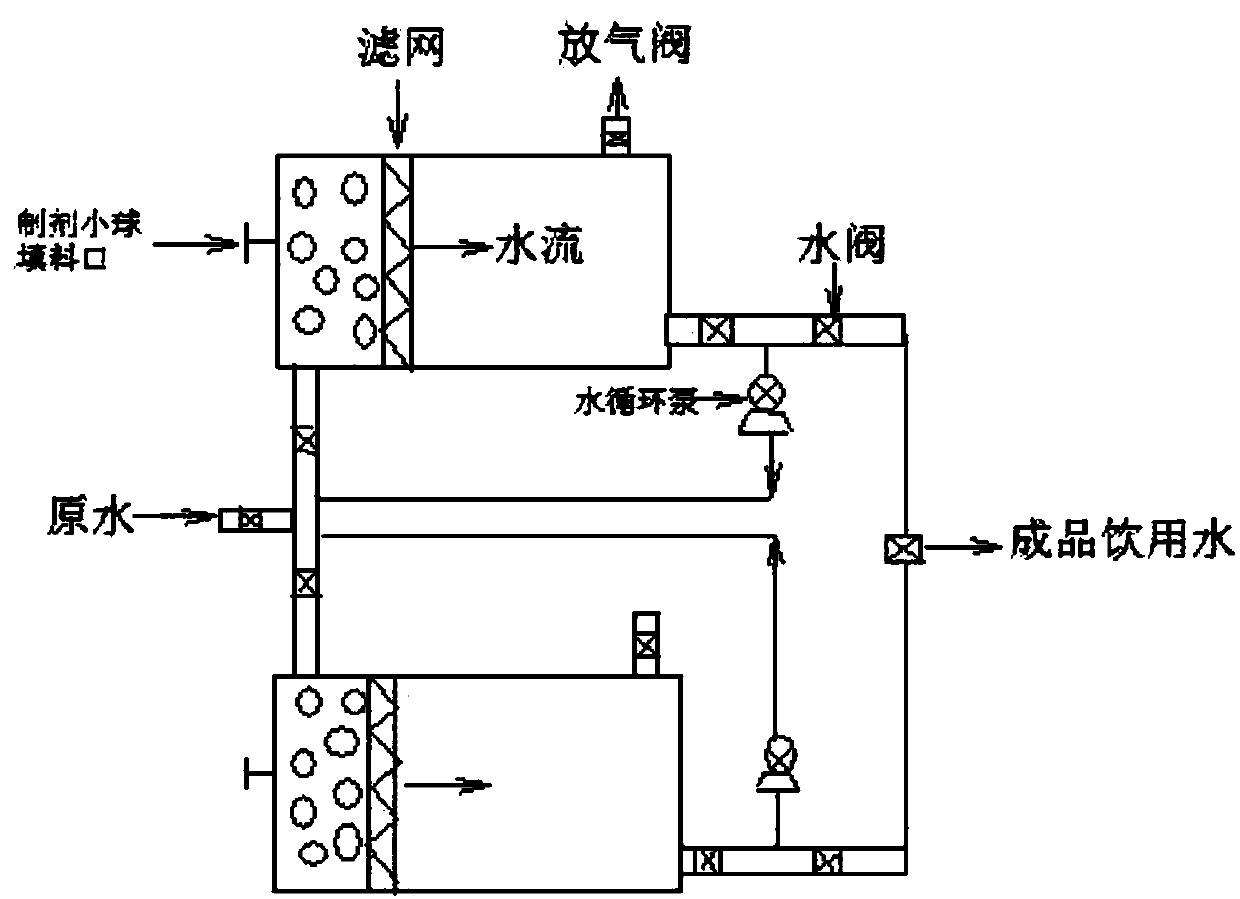

[0045] (4) Br-Cl ion exchange column and ion exchange: put the hybrid pellets into the cylindrical container to equip the hybrid pellet column equipment, then pass the drinking water through the hybrid pellet column equipment, and pass the hybrid pellet The column devices are connected in parallel...

Embodiment 3

[0049] (1) Preparation of silver algae gel: prepare a silver nitrate-sodium alginate sol with a mass ratio of silver nitrate:sodium alginate=1:20 and a mass concentration of 10%; store the silver nitrate-sodium alginate sol in the dark 17h;

[0050] (2) Molding: molding the aged silver nitrate-sodium alginate sol into 2mm pellets through a mold, and reacting in 1% calcium chloride solution at 15°C for 10 hours;

[0051] (3) Purification and removal of impurities: the hybrid pellets obtained in step (2) are washed with water until they are free of calcium ions and chloride ions, and then they are centrifuged, dehydrated, and packaged to obtain a hybrid pellet composed of calcium alginate / AgCl material. small ball;

[0052] (4) Br-Cl ion exchange column and ion exchange: put the hybrid pellets into the cylindrical container to equip the hybrid pellet column equipment, then pass the drinking water through the hybrid pellet column equipment, and pass the hybrid pellet The column...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com