Method for preparing tantalum-based rare earth polyacid and nanocrystal of tantalum-based rare earth polyacid

A technology of rare earth polyacids and nanocrystals, which is applied in the direction of nanotechnology, nanotechnology, polycrystalline material growth, etc., can solve the problems of low efficiency and difficult recovery of catalysts, and achieve the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

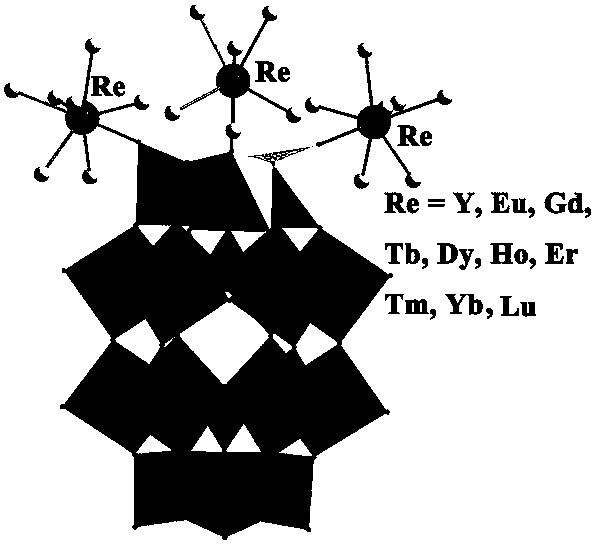

[0022] Preparation of rare earth polyacid Y-POM single crystal product

[0023] Will K 5 Na 4 [P 2 W 15 o 59 (TaO 2 ) 3 ]·17H 2 O (0.20 g, 0.04 mmol) was dissolved in 25 mL deionized water and heated to 75 °C to obtain a light yellow solution; add solid NaHSO 3 (0.04 g, 0.38 mmol) solution became colorless; Y(NO 3 ) 3 ·6H 2 O (0.05 g, 0.15 mmol) was added to the solution; 2 mL of glacial acetic acid (or 1 mL of 1 M hydrochloric acid solution) was added to the solution for acidification, cooled to room temperature and allowed to stand for a week to obtain a Y-POM single crystal product with a final yield of 82%, its structure is as attached figure 1 shown.

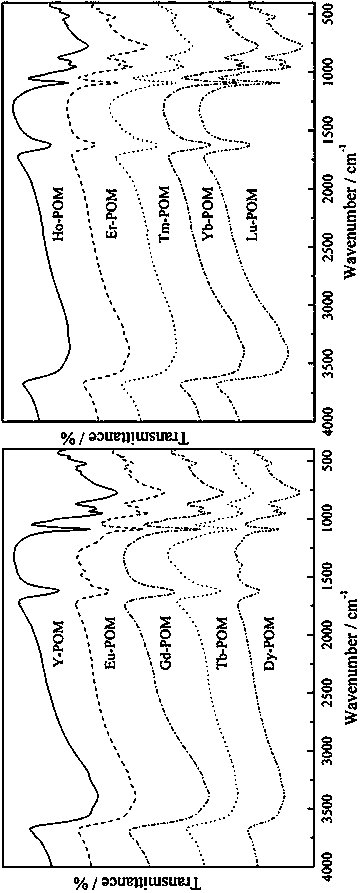

[0024] Preparation of other tantalum-based rare earth polyacid single crystal products

[0025] The synthesis conditions of Eu-POM, Gd-POM, Tb-POM, Dy-POM, Ho-POM, Er-POM, Tm-POM, Yb-POM and Lu-POM are the same as those of Y-POM, except that Y(NO 3 ) 3 ·6H 2 O is replaced by EuCl respectively 3 ·6H 2 O, Gd...

Embodiment 2

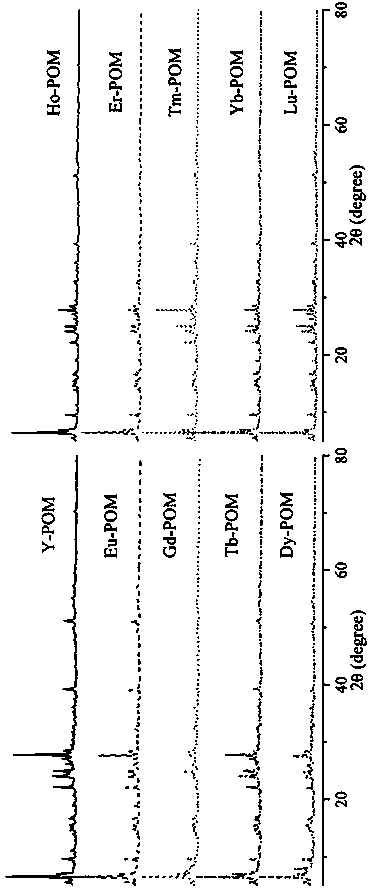

[0027] Preparation of Nanoscale Rare Earth Polyacid Y-POM

[0028] Will K 5 Na 4 [P 2 W 15 o 59 (TaO 2 ) 3 ]·17H 2 O (0.20 g, 0.04 mmol) was dissolved in 25 mL deionized water and heated to 75 °C to obtain a light yellow solution; add solid NaHSO 3 (0.04 g, 0.38 mmol) solution became colorless; Y(NO 3 ) 3 ·6H 2 O (0.1 g, 0.26 mmol) was added to the solution; 1 mL of 1M hydrochloric acid solution was added to the solution for acidification, and then 25 mL of ethanol solution was added, and the resulting solution was continuously stirred for 20 min and cooled naturally to room temperature (the speed was kept at 1000 r / min ), a large amount of fine powder product was formed during this process, the product was collected by filtration and washed with 2.0 mL deionized water and 2.0 mL ethanol, and the yield of the final product was 91%. as attached Figure 4 As shown, its powder XRD pattern is consistent with the single crystal sample, and the SEM electron microscope ph...

Embodiment 3

[0030] Mass Preparation of Nanoscale Rare Earth Polyacid Y-POM

[0031] Will K 5 Na 4 [P 2 W 15 o 59 (TaO 2 ) 3 ]·17H 2 O (2.0 g, 0.4 mmol) was dissolved in 250 mL of deionized water and heated to 75 °C to obtain a pale yellow solution. Add solid NaHSO 3 (0.4 g, 3.8 mmol) The solution became colorless. Then set Y(NO 3 ) 3 ·6H 2 O (1.0 g, 2.6 mmol) was added to the solution; 10 mL of 1M HCl solution was added to the solution for acidification, and 250 mL of ethanol was added. The resulting solution was continuously stirred for 20 minutes and cooled to room temperature naturally. During this process, a large number of fine powder products were formed. The product was collected by filtration and washed with 10 mL of deionized water and 5 mL of ethanol to finally obtain 1.75 g of nano-sized product with a yield of 80%. as attached Figure 4 As shown, its powder XRD is consistent with the single crystal sample. Its particle size and Figure 5 similar in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com