A method and device for measuring the diffusion coefficient of cleaning agent in membrane fouling layer

A diffusion coefficient and cleaning agent technology, which is applied in the field of water treatment, can solve the problems of difficult quantitative monitoring of the cleaning agent diffusion process and the inability to accurately describe the change of cleaning agent diffusion, and achieve short measurement time, good practicability, and low cost of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

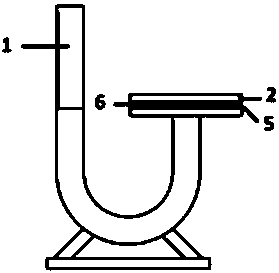

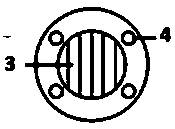

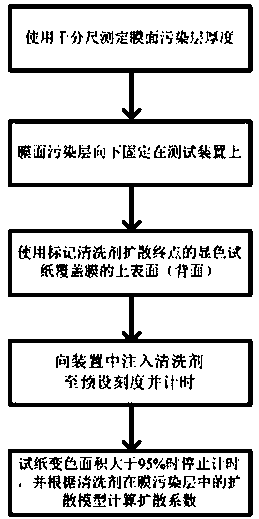

Embodiment 1

[0043] Embodiment 1: use respectively the bovine serum albumin (BSA) solution and sodium alginate (SA) that concentration is 1g / L to pollute ultrafiltration membrane, and measure total available chlorine concentration and be 100mg / L, pH be respectively 5 and 11 Diffusion coefficient of NaClO cleaning agent in two kinds of contamination layers. First, use a micrometer to measure the thickness of the polluted membrane fouling layer. The average thickness of the BSA fouling layer is 210 μm, and the thickness of the SA fouling layer is 213 μm. Use starch potassium iodide test paper as the color test paper. According to the above operation method, fix the membrane on the osmosis device and add cleaning agent so that the water head on one side of the U-shaped tube is 0.5cm higher than the membrane surface, and use a stopwatch to time. After repeating the above experiment three times, it was found that in the BSA pollution layer, the average diffusion time of the cleaning agent with ...

Embodiment 2

[0044] Embodiment 2: on the basis of the experiment described in embodiment 1, add the sodium dodecyl sulfate (SDS) of 0.5mmol / L in cleaning agent to further improve the diffusion rate of cleaning agent, and repeat above-mentioned diffusion coefficient determination experiment . Use NaClO cleaning agent with a total available chlorine concentration of 100mg / L, an SDS concentration of 0.5mmol / L, and a pH of 5 and 11, respectively, to measure its diffusion process in the two pollution layers of BSA and SA, record the diffusion time and follow the test The diffusion coefficient calculation formula derived in the method was used to calculate the diffusion coefficient. The measurement results show that: in the BSA pollution layer, the diffusion coefficient of the cleaning agent at pH=5 after adding SDS is 7.68×10 - 8 cm / s is significantly greater than 4.99×10 without adding SDS -8 cm / s; the diffusion coefficient of the cleaning agent with pH=11 is 14.3×10 - 8 cm / s is significa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com