A kind of nanometer metal/red phosphorus composite material and preparation method thereof

A nano-metal and composite material technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of simple preparation method, uniform size and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the nano metal / red phosphorus composite material of the present invention includes the following steps:

[0028] Dissolve the nano metal soluble salt in water to obtain the nano metal precursor aqueous solution, mix the nano metal precursor aqueous solution with the nano red phosphorous dispersion liquid, stir uniformly, carry out the in-situ reduction compound reaction, and then the reactant is filtered, washed with water, and dried Obtain nano-metal / red phosphorus composite material.

[0029] Specifically, the nano-metal soluble salt is copper sulfate, copper nitrate, copper chloride, silver nitrate or chloroauric acid.

[0030] The concentration of the nano-metal precursor aqueous solution in the mixed solution is 0.1-2.0 mmol / L.

[0031] The reaction temperature of the nano-metal precursor aqueous solution and the nano-red phosphorus dispersion is 30-150°C, and the reaction time is 0.5-2h.

[0032] The dripping process of the nano red phosphorous di...

Embodiment 1

[0041] At room temperature, the commercially available red phosphorus was ground in water, sieved with a 120-mesh screen and dried to obtain micron red phosphorus particles. Weigh 3g and disperse in a reaction consisting of 55mL water, 5mL ethylene glycol, and 0.12g NaOH. In the liquid, stir for 30min, transfer to a 100mL hydrothermal synthesis reaction tank with polytetrafluoroethylene lining, place it in a blast drying box after sealing, heat up at 5℃ / min to 200℃ for 24h, and cool naturally after the reaction is complete To room temperature, the product was repeatedly washed with distilled water and absolute ethanol and centrifuged (12000rmp / min). After the product was dried at 80℃, it was annealed at 380℃ for 1h under the protection of argon. Finally, 1.0g product was dispersed in 500mL In water, 300W, 20KHz ultrasonic for 10h was used to obtain nano red phosphorus dispersion (reaction liquid A).

Embodiment 2

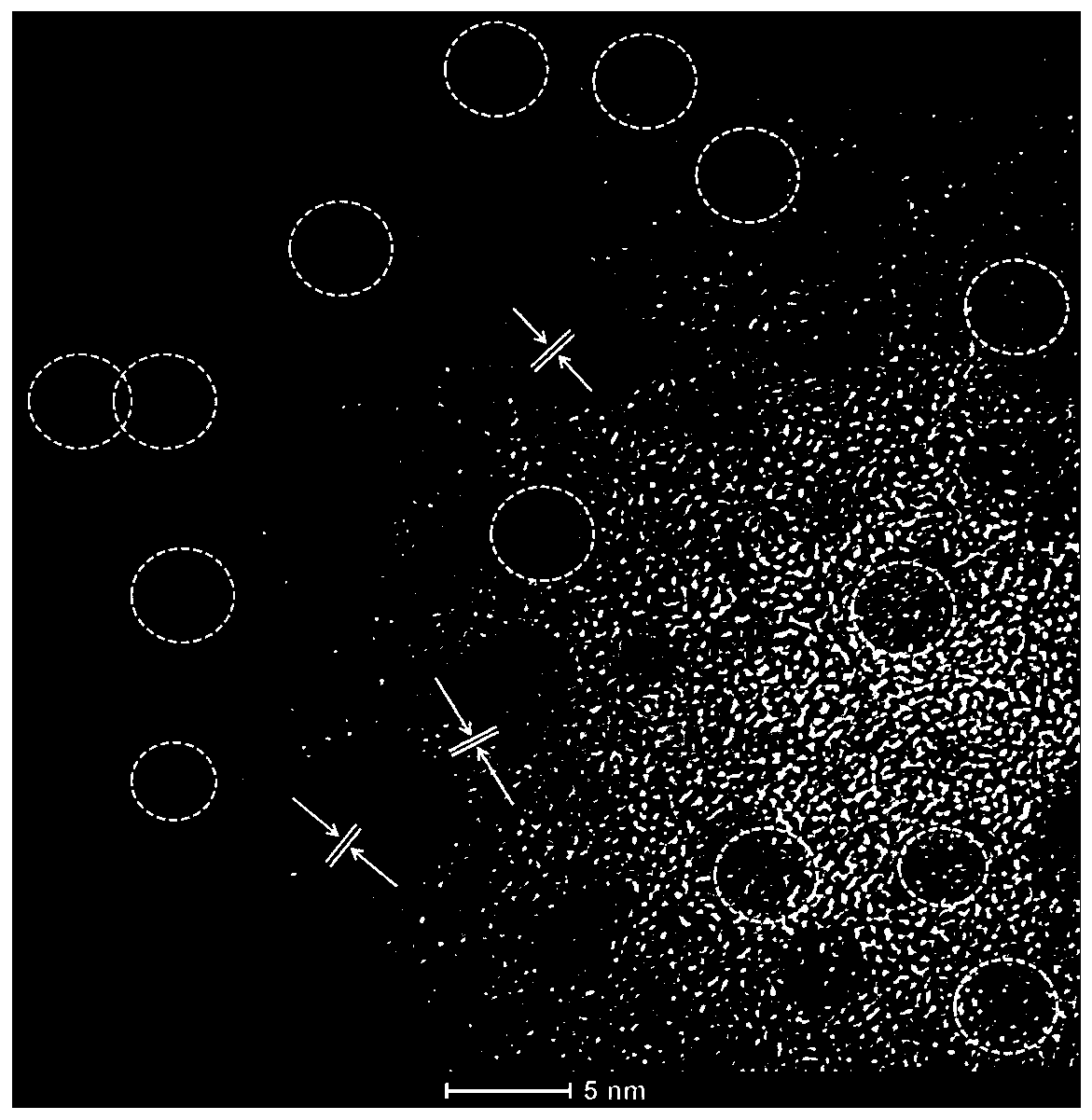

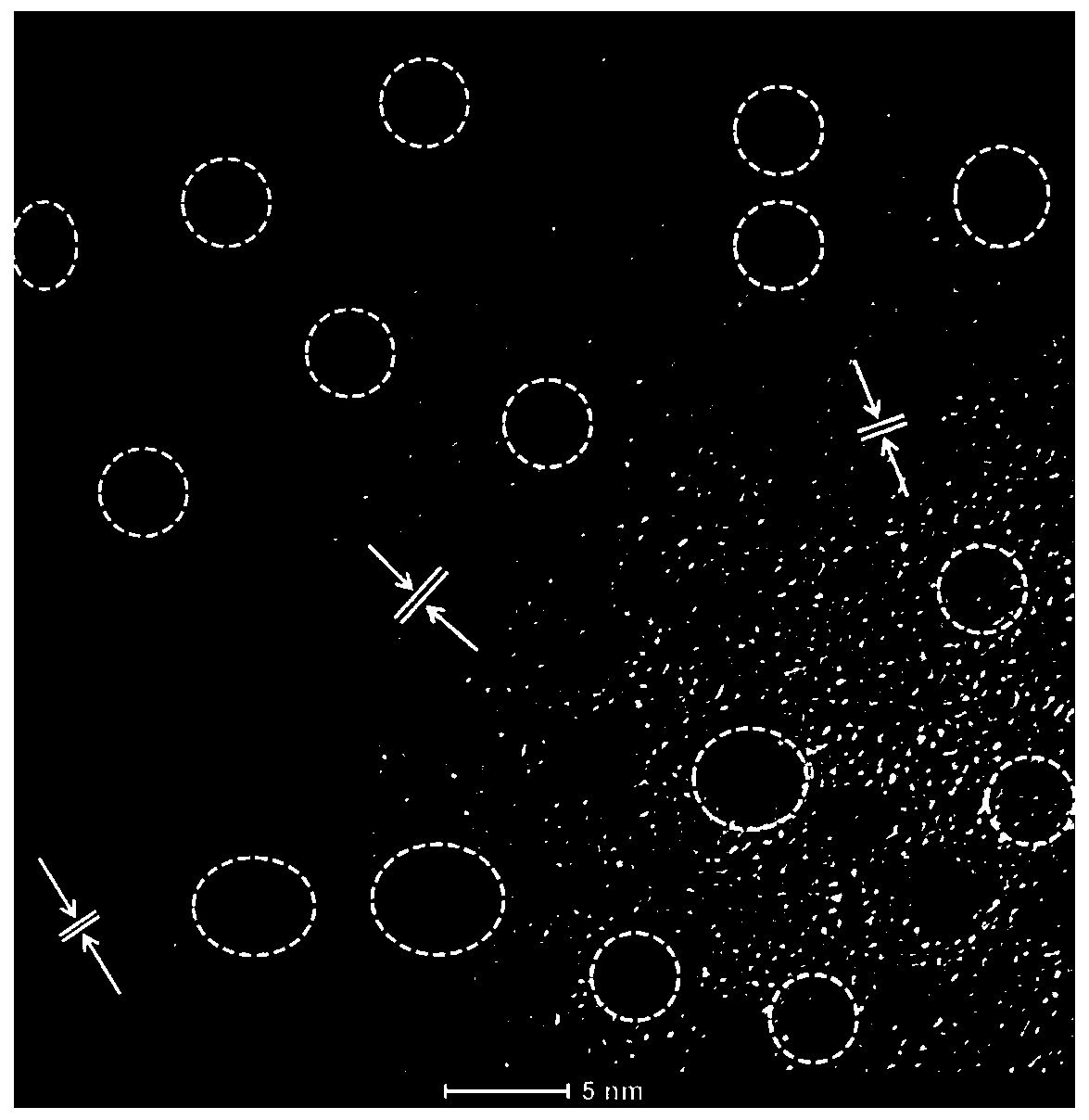

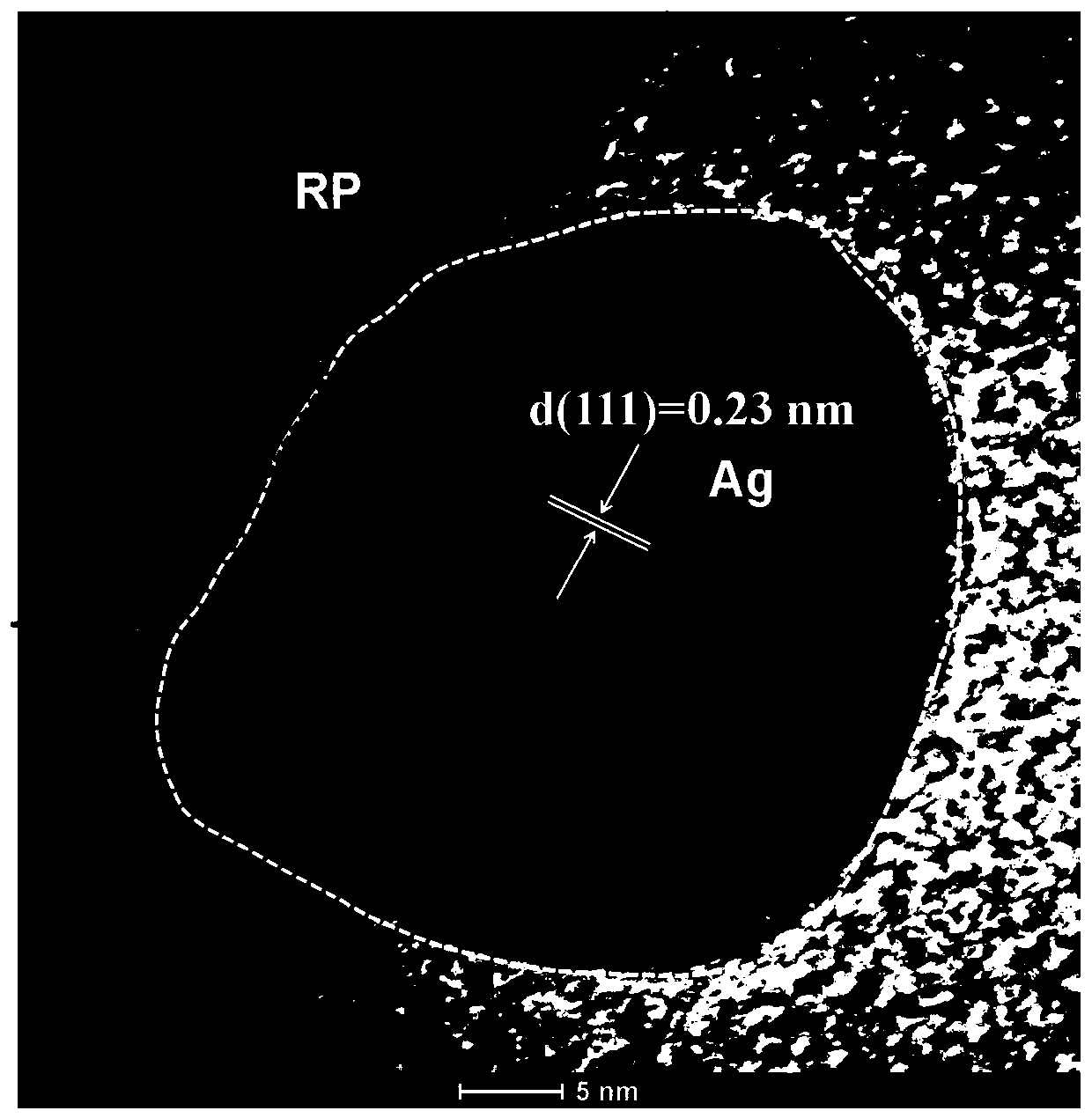

[0043] Weigh 0.021g CuSO 4 ·5H 2 O was dissolved in 40mL of water (reaction solution B); then take 40mL of reaction solution A in Example 1, add it dropwise to reaction solution B within 30 minutes, continue stirring for 30 minutes, and then transfer to the hydrothermal synthesis reactor (lined 100mL polytetrafluoroethylene), sealed and placed in a blast drying box, heated at 5°C / min to 150°C and kept for 2h. After the reaction is completed, it is naturally cooled to room temperature. The product is filtered with a 200nm filter membrane and rinsed repeatedly with distilled water , The solid product is dried at 60 ℃ to obtain nano-copper / red phosphorus composite material. Such as figure 1 In the white circle part is nano metal copper, RP represents red phosphorus, figure 1 It can be seen that the nano-copper particles are uniformly distributed on the surface of red phosphorus, with a particle size of about 4nm; Figure 5 It can be seen that under visible light, the photocurrent o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com