Preparation method for graphene oxide

A graphene and graphene technology, which is applied in the field of graphene oxide preparation, can solve the problems of generating harmful gas, complicated processes, and the like, and achieves the effects of good dispersion and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

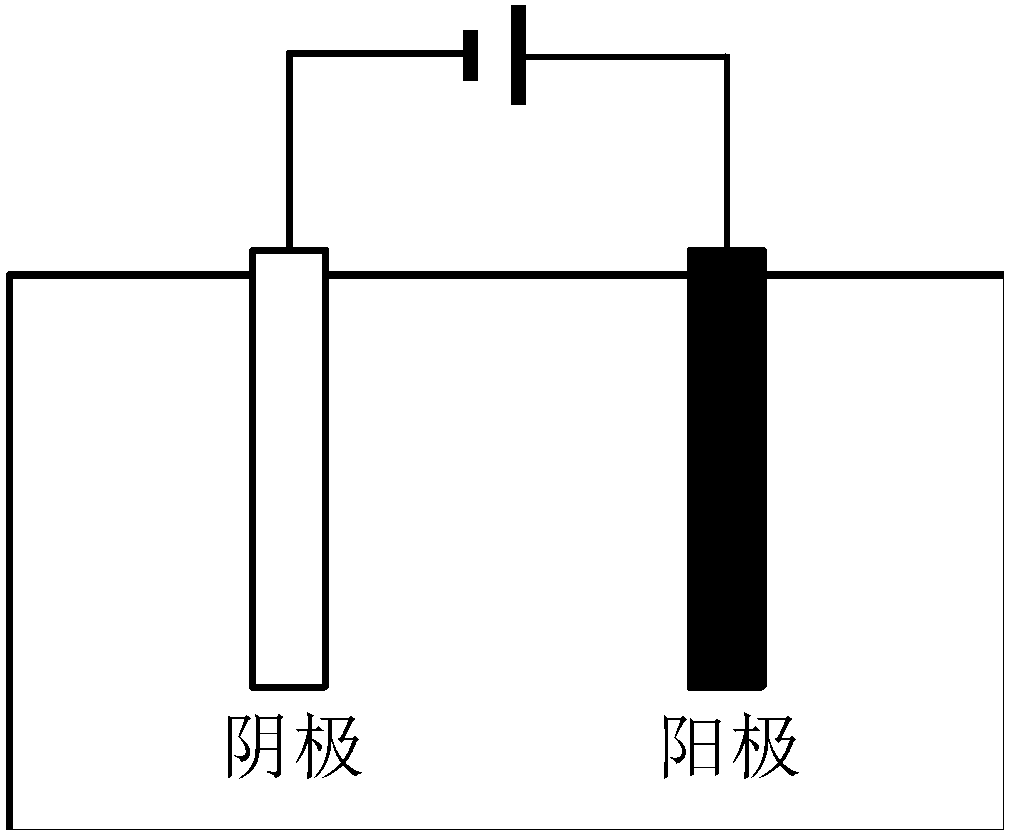

[0022] The embodiment of the present invention provides a kind of preparation method of graphene oxide, and this method mainly comprises the following steps:

[0023] The carbon-containing carbon source is used as the anode, and the conductive material is placed in the electrolyte water as the cathode;

[0024] The solution of graphene oxide is obtained by applying direct current to the anode and the cathode for more than 3 minutes;

[0025] The graphene oxide solution is dried to obtain graphene oxide.

[0026] The invention provides a kind of preparation method of graphene oxide, such as figure 1 as shown, figure 1 In order to prepare graphene oxide devices, water is used as the electrolyte. When direct current is applied, water molecules are ionized into hydrogen ions and hydroxide ions. Under the action of an external electric field, the negatively charged hydroxide ions move to the anode and enter the Hydroxide ions in the anode will pull the graphite layer from the an...

Embodiment 1

[0033] will be 10cm 2 graphite as anode, 15cm 2 The stainless steel sheet is placed in the tap water of the electrolyte as the cathode, and the distance between the graphite and the stainless steel sheet is 5cm;

[0034] Connect the graphite to the positive pole of the DC power supply, connect the stainless steel sheet to the negative pole of the DC power supply, and obtain a solution of graphene oxide under the conditions of a DC current of 4, 20 and 30 milliamperes and a power-on time of 5 days;

[0035] The graphene oxide solution is filtered and dried to obtain graphene oxide.

[0036] Among them, please refer to figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6, figure 2 For the solution of the graphene oxide that embodiment 1 prepares, to figure 2 After filtering and drying the graphene oxide solution in the solution, scanning electron microscopy, transmission electron microscopy and ultraviolet spectrum testing are carried out, such as Figure 3 to F...

Embodiment 2

[0038] will be 150cm 2 CFRP cloth as anode, 15cm 2 The stainless steel sheet is placed in the tap water of the electrolyte as the cathode, and the distance between the carbon fiber and the graphite is 5cm;

[0039] The CFRP cloth is connected to the positive pole of the DC power supply, and the stainless steel sheet is connected to the negative pole of the DC power supply. Under the condition of a DC current of 10 mA and a power-on time of 5 days, a solution of graphene oxide is obtained;

[0040] The graphene oxide solution is filtered and dried to obtain graphene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com