Vanadate luminescent material and preparation method thereof

A technology of luminescent materials and vanadate, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unstable white light emission, weak emission in the red light band, and easy deliquescence of luminescent materials, and achieve enhanced luminous intensity and equipment requirements Low, easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

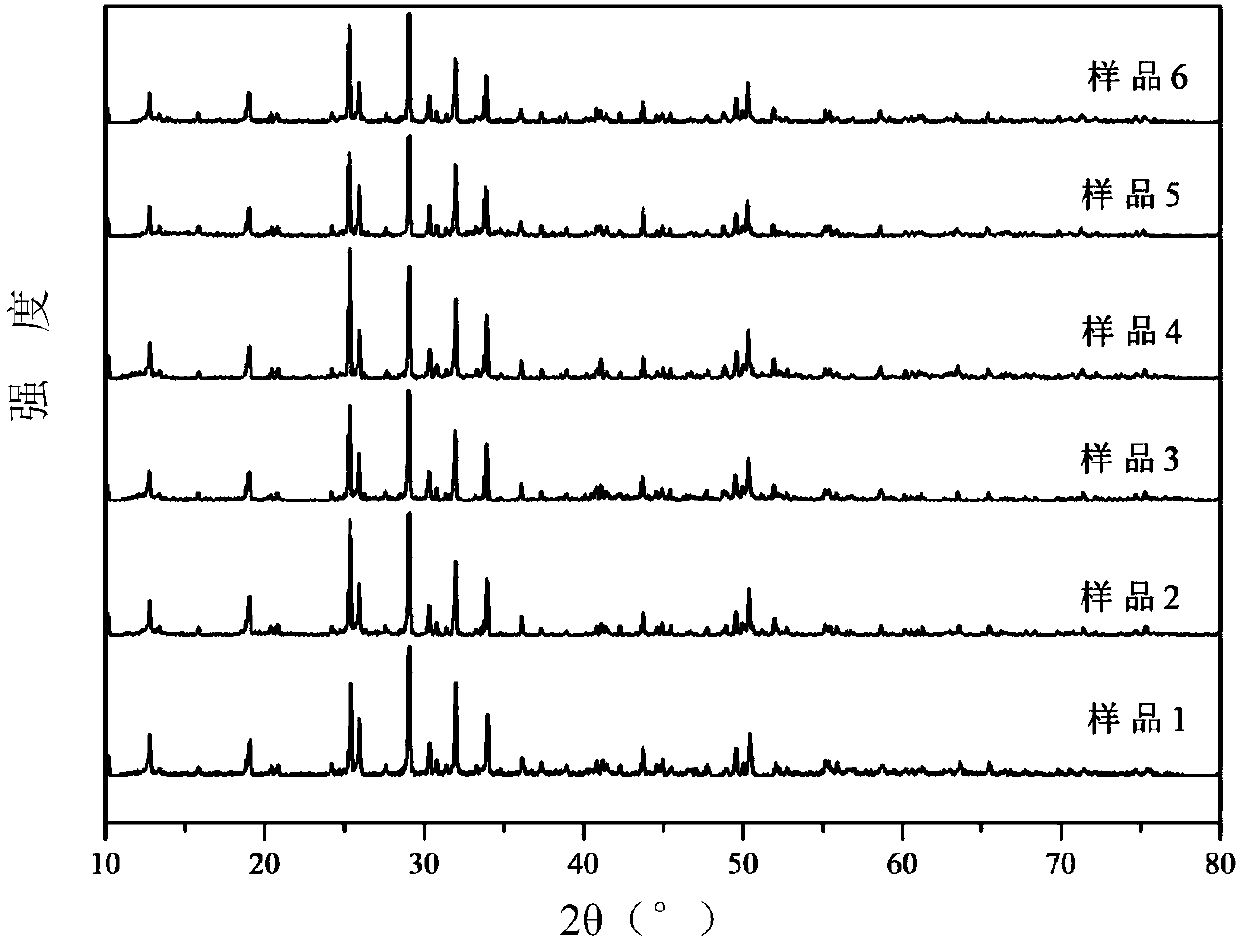

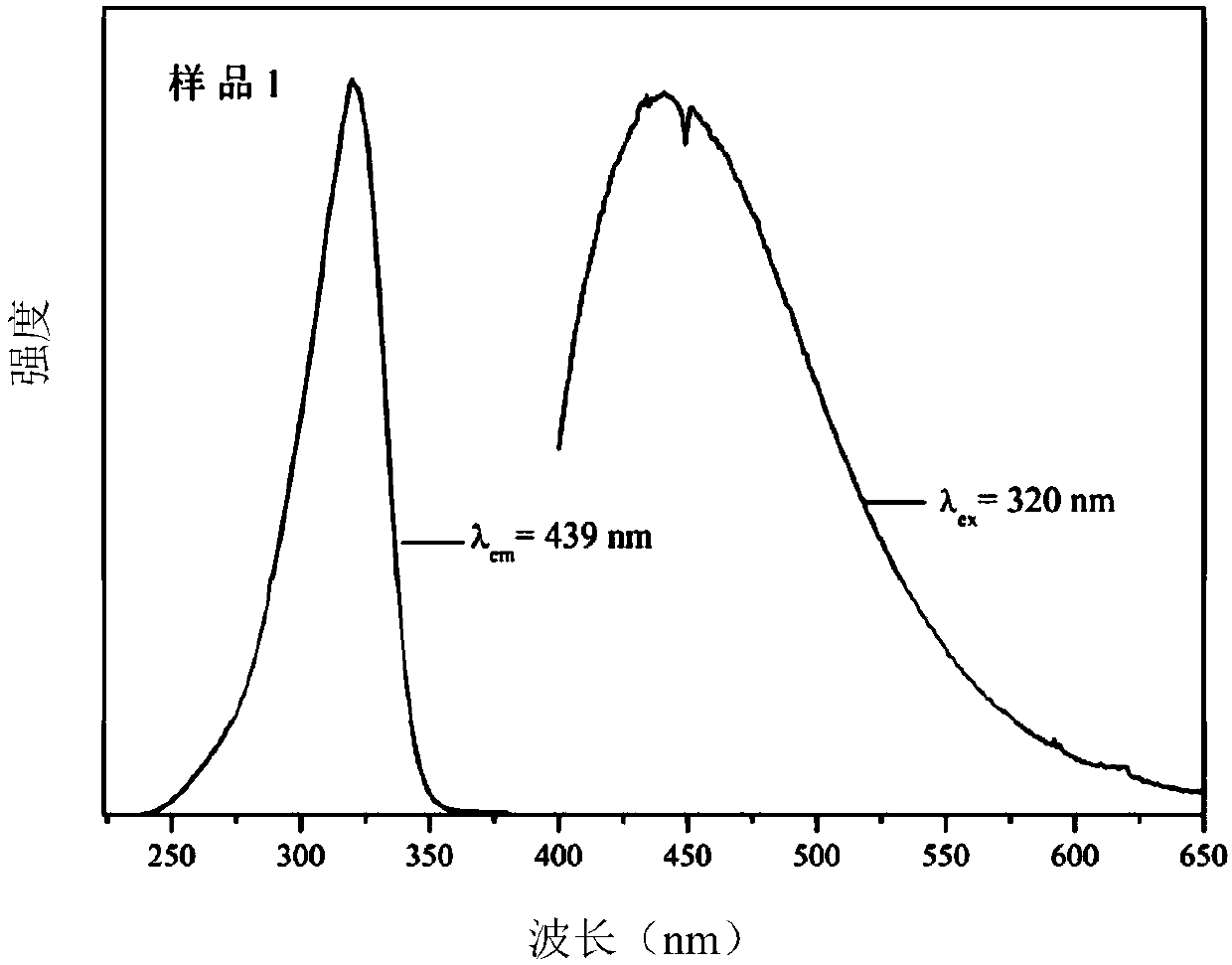

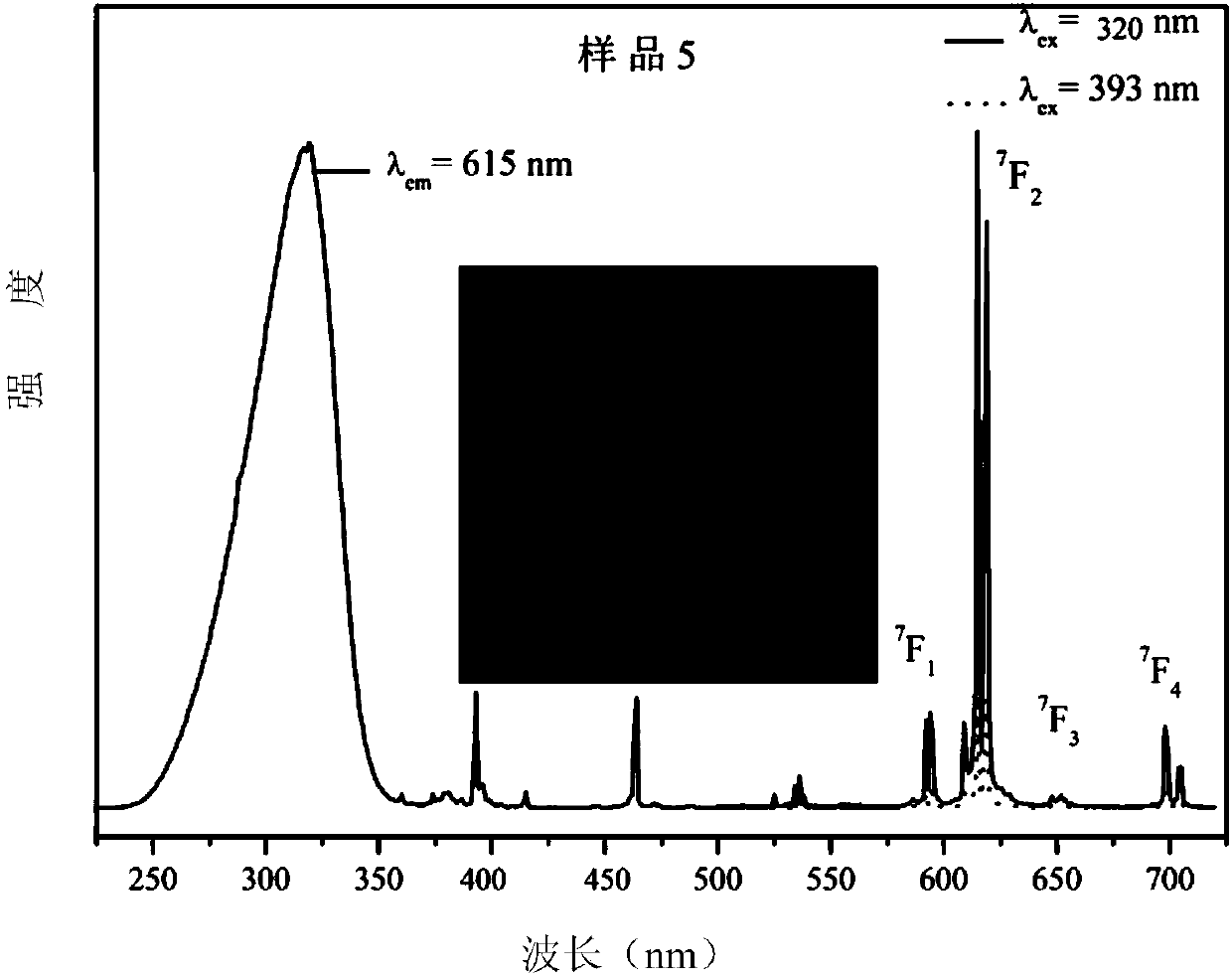

[0035] The composition of the vanadate luminescent material in this embodiment is Sr 3 Lu 1-x (VO 4 ) 3 :xEu 3+ , wherein, x is respectively 0, 0.007, 0.009, 0.02, 0.04, 0.06 (the sample numbers are 1-6 respectively), and the component formula of each sample is shown in Table 1 below.

[0036] The corresponding raw materials and quality (g) of each sample in Table 1

[0037]

[0038] *Note: Sample 1 in Table 1 is the control group, which is not doped with Eu 3+ Sr and Lu vanadates.

[0039] Prepare samples 1-6 according to the formula dosage of each sample in Table 1, the process is as follows: weigh a certain amount of strontium carbonate SrCO 3 , Lanthanum oxide Lu 2 o 3 , europium oxide Eu 2 o 3 and ammonium metavanadate NH 4 VO 3 , after grinding in an agate mortar and mixing evenly, put the obtained grinding mixture into a corundum crucible, and place it in a muffle furnace, and select an air atmosphere for sintering. Burn for 6 hours, then heat up to 900°...

Embodiment 2

[0054] The composition of the vanadate luminescent material in this embodiment is Sr 3 La 0.97 (VO 4 ) 3 :0.03Eu 3+ , and its preparation process is as follows: According to the general chemical formula Sr 3 La0.97 (VO 4 ) 3 :0.03Eu 3+ , respectively weigh a certain amount of strontium oxide SrO, lanthanum oxide La 2 o 3 , europium oxide Eu 2 o 3 and vanadium pentoxide V 2 o 5 , after being ground in an agate mortar and mixed evenly, the obtained grinding mixture is put into a corundum crucible and placed in a muffle furnace, and the air atmosphere is selected for sintering. Burn for 4 hours, then heat up to 800°C and calcined for 10 hours, then cool to room temperature with the furnace, take out the sample and grind it into powder, and the general chemical formula is Sr 3 La 0.97 (VO 4 ) 3 :0.03Eu 3+ vanadate luminescent material.

Embodiment 3

[0056] The composition of the vanadate luminescent material in this embodiment is Ca 3 Y 0.95 (VO 4 ) 3 :0.05Eu 3+ , the preparation process is as follows: Weigh a certain amount of calcium carbonate CaCO 3 , Y 2 o 3 , europium acetate (CAS No.62667-64-5) and ammonium metavanadate NH 4 VO 3 , after grinding and mixing uniformly in an agate mortar, put the obtained grinding mixture into a corundum crucible, and place it in a muffle furnace, select an air atmosphere for sintering, wherein, the specific procedure for sintering is: first raise the temperature to 200°C Burn for 5 hours, then heat up to 850°C for 9 hours, then cool to room temperature with the furnace, take out the sample and grind it into powder, and the general chemical formula is Ca 3 Y 0.95 (VO 4 ) 3 :0.05Eu 3+ vanadate luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com