System and method for producing mesophase pitch and oil products on the basis of hydrogenation of medium and low temperature coal tar

A technology of low-temperature coal tar and mesophase pitch, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, tar pitch/petroleum pitch/natural pitch, and tar processing by distillation, etc. Effective removal of problems such as rapid increase in bed pressure drop, to achieve the effects of improving high added value and economy, ensuring stable operation of the process, and extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will now be further described in conjunction with the drawings and embodiments, but the present invention is not limited to the following implementation situations.

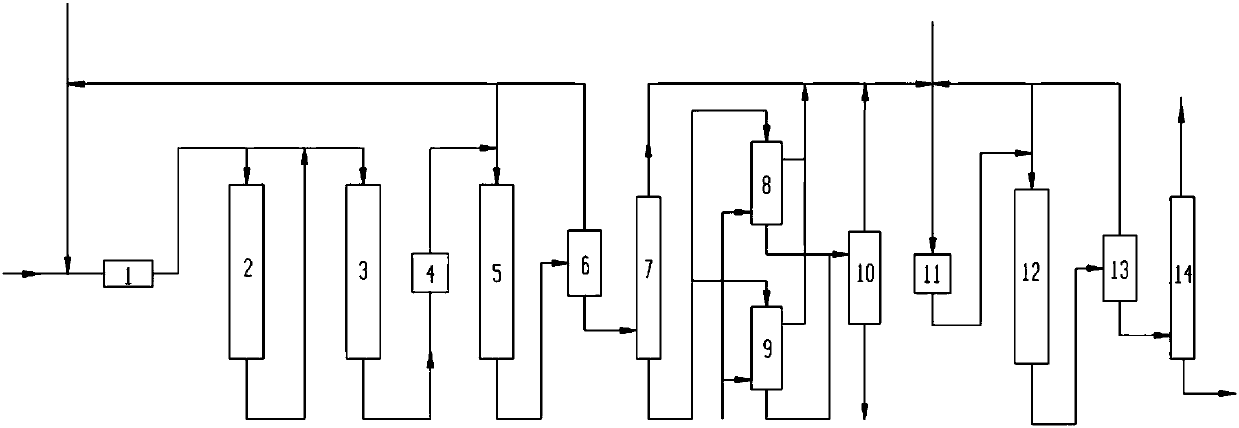

[0051] see figure 1 In this example, the system for producing mesophase pitch and oil products based on medium and low temperature coal tar hydrogenation mainly includes coal tar pretreatment unit, coal tar hydrogenation deasphalting unit, heavy component heat condensation reaction unit and light component hydrofining unit; the coal tar pretreatment unit is composed of an electric desalination device and an automatic backwash filter device; the coal tar hydrodeasphalting unit is composed of a coal tar preheater 1, a first protection and demetallization reactor 2, a second protection and deasphalting Metal reactor 3, coal tar heating furnace 4, deasphalting reactor 5, first high-pressure separator 6 and first fractionation tower 7 are connected; The polycond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com