A filter film for purifying organic pollutants in indoor air and preparation method thereof

A technology of organic pollutants and internal air, applied in the field of indoor air purification, can solve the problems of poor mechanical properties of activated carbon materials, reduce adsorption capacity, and long production cycle, and achieve the effects of facilitating industrial production, improving purification efficiency, and killing bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

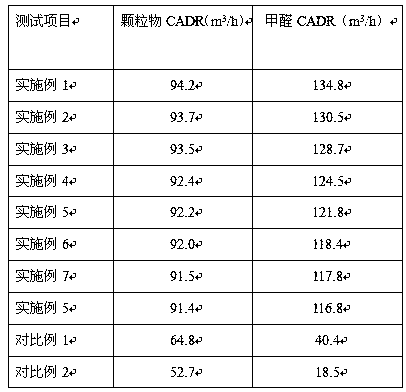

Examples

Embodiment 1

[0039] A preparation method of a filter film for purifying organic pollutants in indoor air:

[0040] (1) Disperse glycidyl methacrylate into acetone, and ultrasonically disperse it for 20 minutes at 500W, then add divinylbenzene to it, continue to stir evenly, then add azobisisobutyronitrile, and add after stirring and mixing. Polyoxyethylene fatty amine, add potassium sulfate solution under stirring condition, and continue stirring to form emulsion;

[0041] (2) Add zeolite powder, tourmaline powder, germanium rare earth powder and nano-titanium dioxide to the emulsion, and stir to obtain mixture 1;

[0042] (3) mixing the mixture 1 in step (2) with the gel material to obtain a sol;

[0043] (4) Spray the sol evenly on the non-woven fabric, then drive the substrate to rotate so that the glue on the substrate forms a film layer, stop the rotation of the substrate after the distribution of the glue is stable, and inject again at the center of the substrate. Glue, then drive ...

Embodiment 2

[0045] A preparation method of a filter film for purifying organic pollutants in indoor air:

[0046] (1) Disperse glycidyl methacrylate into N,N-dimethylformamide, ultrasonically disperse for 15 minutes at 400W, add divinylbenzene, continue to stir evenly, and then add azobis Isobutyronitrile, add polyoxyethylene fatty acid ester after stirring and mixing, add potassium sulfate solution under stirring condition, and continue stirring to form emulsion;

[0047] (2) Add bentonite, tourmaline powder, far-infrared powder and nano-titanium dioxide to the emulsion, and stir to obtain mixture 1;

[0048] (3) mixing the mixture 1 in step (2) with the gel material to obtain a sol;

[0049] (4) Spray the sol evenly on the non-woven fabric, then drive the substrate to rotate so that the glue on the substrate forms a film layer, stop the rotation of the substrate after the distribution of the glue is stable, and inject again at the center of the substrate. Glue, then drive the substrat...

Embodiment 3

[0051] A preparation method of a filter film for purifying organic pollutants in indoor air:

[0052] (1) Disperse glycidyl methacrylate into N-methylpyrrolidone, disperse by ultrasonic for 12 minutes at 600W, add divinylbenzene, continue to stir evenly, and then add azobisisobutyronitrile, After stirring and mixing, add polyoxyethylene amide, add potassium sulfate solution under stirring conditions, and continue stirring to form an emulsion;

[0053] (2) Add diatomite, tourmaline powder, far-infrared powder and nano-titanium dioxide to the emulsion, and stir to obtain mixture 1;

[0054] (3) mixing the mixture 1 in step (2) with the gel material to obtain a sol;

[0055] (4) Spray the sol evenly on the non-woven fabric, then drive the substrate to rotate so that the glue on the substrate forms a film layer, stop the rotation of the substrate after the distribution of the glue is stable, and inject again at the center of the substrate. Glue, then drive the substrate to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com