A process for efficiently enriching copper and indium in zinc sulfide concentrate

A zinc sulfide concentrate and high-efficiency technology, which is applied in photography technology, photography auxiliary technology, sulfur preparation/purification, etc., can solve the problems of electrolytic zinc production and copper enrichment, iron removal cost and iron slag increase, indium slag grade, poor quality, etc., to achieve the effect of improving the total zinc recovery rate, ensuring the total recovery rate, and high grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

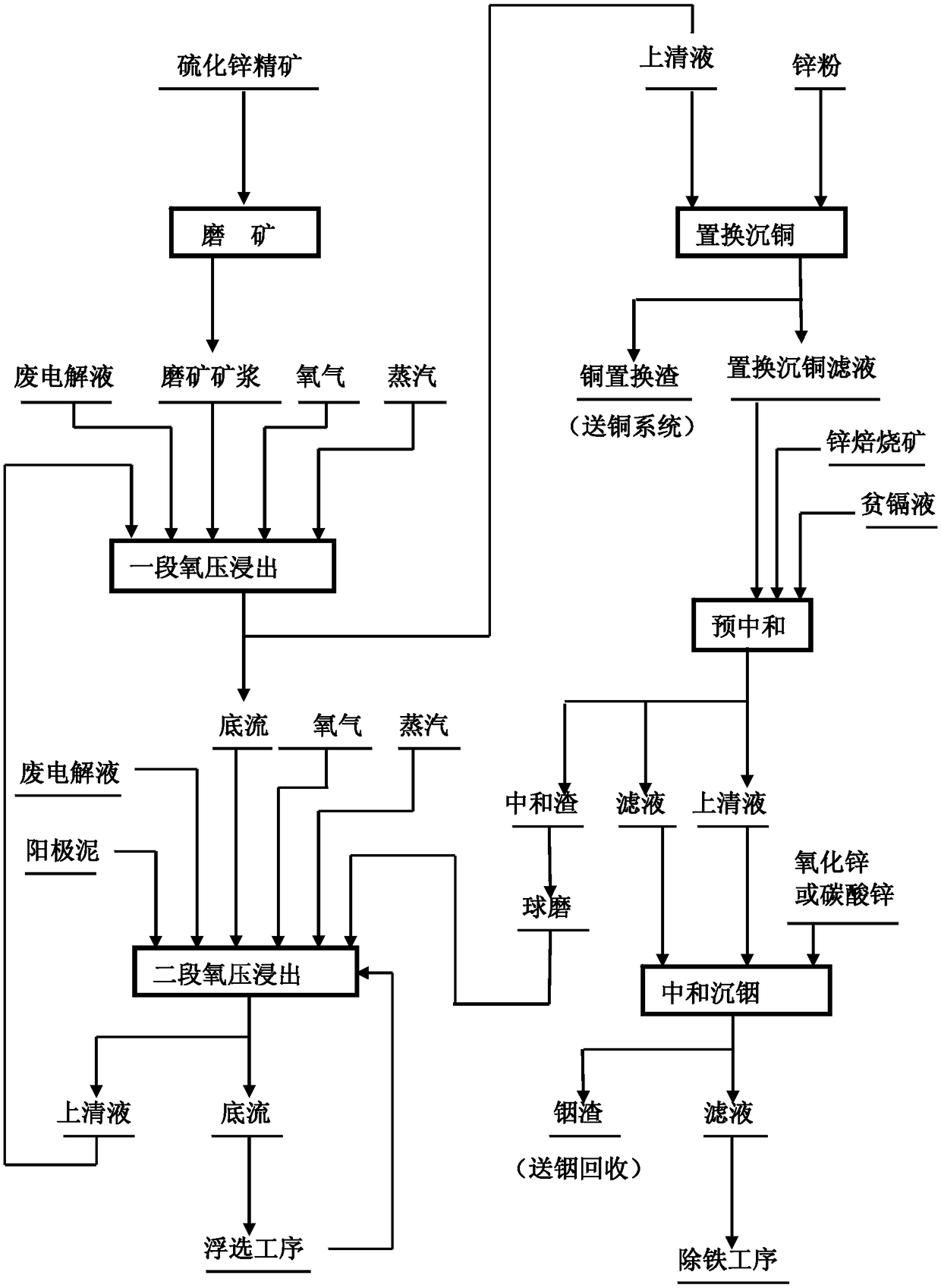

[0027] A process for efficiently enriching copper and indium in zinc sulfide concentrate is characterized in that it comprises the following steps:

[0028] (1) Grinding: put the crushed and screened zinc sulfide concentrate into the storage bin, after being measured, enter the high-efficiency slurry tank for slurry treatment, and then pump it into the vertical grinding machine for grinding, and the output More than 98% of the particle size of the zinc concentrate material is less than 44μm grinding slurry, and the solid content of the grinding slurry is 65%;

[0029](2) One-stage oxygen pressure leaching: the ground ore slurry flows into the middle tank, and is pumped to the one-stage leaching feeding stirring tank, and the one-stage leaching slurry after stirring and mixing is pumped to the first section of the one-stage leaching horizontal autoclave. During the pumping process, the autoclave slurry metering pump is used to control the flow rate, and steam and oxygen are int...

Embodiment 2

[0036] A process for efficiently enriching copper and indium in zinc sulfide concentrate is characterized in that it comprises the following steps:

[0037] (1) Grinding: put the crushed and screened zinc sulfide concentrate into the storage bin, after being measured, enter the high-efficiency slurry tank for slurry treatment, and then pump it into the vertical grinding machine for grinding, and the output More than 98% of the particle size of the zinc concentrate material is less than 44μm grinding slurry, and the solid content of the grinding slurry is 66%;

[0038] (2) One-stage oxygen pressure leaching: the ground ore slurry flows into the middle tank, and is pumped to the one-stage leaching feeding stirring tank, and the one-stage leaching slurry after stirring and mixing is pumped to the first section of the one-stage leaching horizontal autoclave. During the pumping process, the autoclave pulp metering pump is used to control the flow rate, and steam and oxygen are intr...

Embodiment 3

[0045] A process for efficiently enriching copper and indium in zinc sulfide concentrate is characterized in that it comprises the following steps:

[0046] (1) Grinding: put the crushed and screened zinc sulfide concentrate into the storage bin, after being measured, enter the high-efficiency slurry tank for slurry treatment, and then pump it into the vertical grinding machine for grinding, and the output More than 98% of the particle size of the zinc concentrate material is less than 44μm grinding slurry, and the solid content of the grinding slurry is 67%;

[0047] (2) One-stage oxygen pressure leaching: the ground ore slurry flows into the middle tank, and is pumped to the one-stage leaching feeding stirring tank, and the one-stage leaching slurry after stirring and mixing is pumped to the first section of the one-stage leaching horizontal autoclave. During the pumping process, the autoclave slurry metering pump is used to control the flow rate, and steam and oxygen are in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com