Method for preparing electronic grade ethylene carbonate by falling film crystallization

A technology of ethylene carbonate and falling film crystallization, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of unfavorable lithium-ion battery electrolyte, high operating conditions, and poor lithium-ion batteries, and achieve considerable economic benefits , Reduce energy consumption, increase output and product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0066] As an optional implementation, the method includes the following steps:

[0067] (a) Preheating: Preheat the ethylene carbonate raw material to 39-50°C, keep the temperature constant for 10-60 minutes, and then use a pump to transport the raw material to the crystallizer;

[0068] (b) Feeding: raw materials are fed from the top of the crystallizer, so that the raw materials are circulated between the crystallizer and the raw material storage tank at a flow rate of 100t / h~300t / h, and the temperature of the crystallizer is controlled at 25~35°C;

[0069] (c) Cooling crystallization: crystallize by gradually cooling down, so that ethylene carbonate forms a crystal layer on the wall of the crystallizer, the cooling step is 0.5 ° C / h ~ 3 ° C / h, the cooling end temperature is 15 ~ 35 ° C, crystallization Stop feeding after 2-13 hours, then keep the temperature for 1-3 hours, discharge the uncrystallized ethylene carbonate residual liquid from the material outlet of the cr...

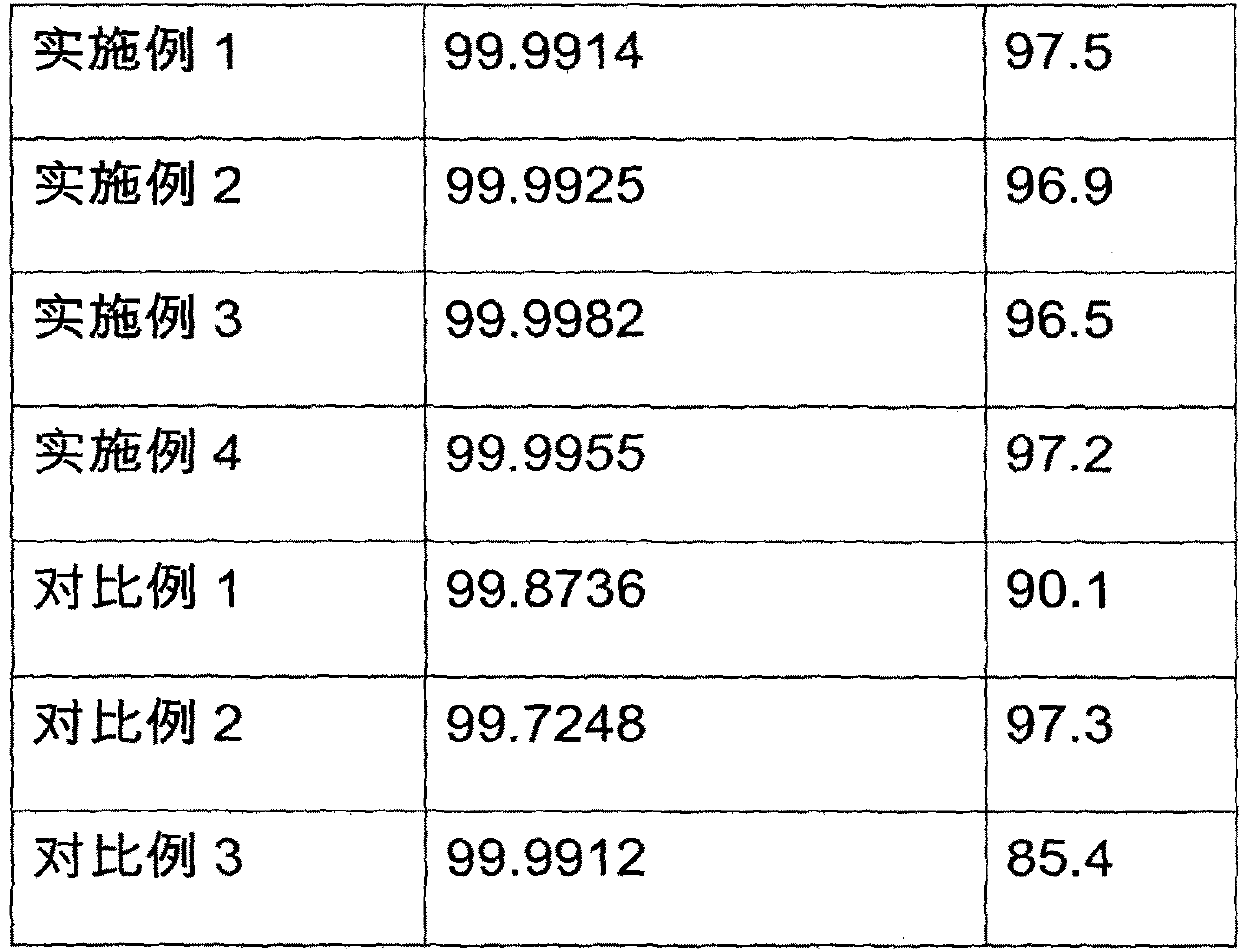

Embodiment 1

[0077]The present embodiment provides a method for preparing electronic-grade ethylene carbonate by falling film crystallization, comprising the following steps:

[0078] (a) add ethylene carbonate raw material from crystallizer top with pump, make ethylene carbonate circulate between crystallizer and ethylene carbonate raw material storage tank by 100t / h flow rate, crystallizer wall temperature temperature drops to 35 ℃;

[0079] (b) Carry out crystallization by gradually lowering the temperature, so that ethylene carbonate forms a crystal layer on the wall of the crystallizer, and the temperature at the end point of cooling is 30°C. Stop feeding after 2 hours of crystallization, and then keep the temperature for 1 hour, and remove the uncrystallized ethylene carbonate residual liquid It is discharged from the material outlet of the crystallizer and transported to the recovery device;

[0080] (c) The crystal layer is melted by heating and sweating in two steps, and the sweat...

Embodiment 2

[0083] The present embodiment provides a method for preparing electronic-grade ethylene carbonate by falling film crystallization, comprising the following steps:

[0084] (a) ethylene carbonate raw material is added from crystallizer top with pump, makes ethylene carbonate circulate between crystallizer and ethylene carbonate raw material storage tank by 200t / h flow rate, and crystallizer wall temperature temperature drops to 30 ℃;

[0085] (b) Carry out crystallization by gradually lowering the temperature, so that ethylene carbonate forms a crystal layer on the wall of the crystallizer. The end point temperature of cooling is 26° C., stop feeding after 5 hours of crystallization, and then keep the temperature for 2 hours to remove the uncrystallized ethylene carbonate residue. It is discharged from the material outlet of the crystallizer and transported to the recovery device;

[0086] (c) The crystal layer is melted by heating and sweating in three steps, and the sweating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com